- Joined

- May 27, 2016

- Messages

- 3,479

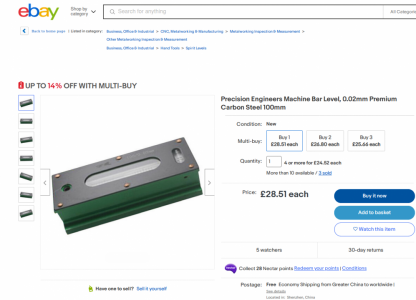

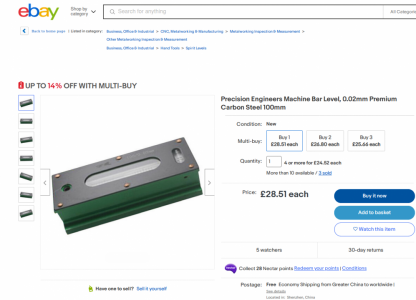

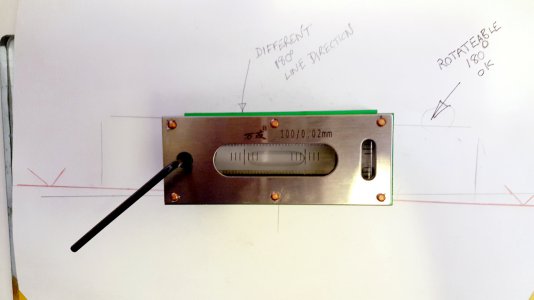

100mm (4") Wanyou 0.02mm/m from eBay UK

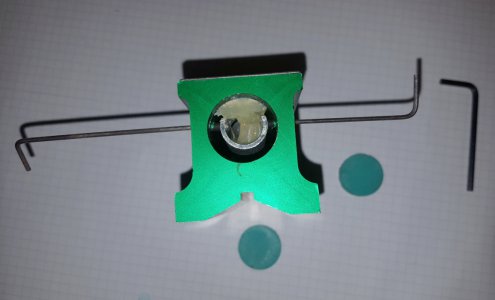

Here we have a take-apart of probably one of the cheapest levels available via eBay.

I have two of them, and I only wanted them as a source of sensitive level vials I could fix onto (my version) homebrew Kingway tool.

I thought that things might go easier if one could have them with the vials already mounted into something that could easily clamp/fix onto a Kingway crossbar.

They have an "adjustment screw", so we at least have a little try-out. It did not go well!

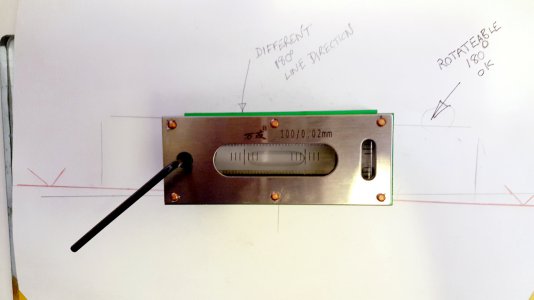

The self-calibration recipe(s) are well known. Start with you assume the level is wrong, and also, your level surface isn't (level). Throw in that it needs to be flat (enough) and stiff (enough). Done on a 3/8" thick plate glass on the green cutting mat, on the desk, it can see a deflection from a smartphone being placed on the desk to the side. The 0.02mm/m choice is probably too sensitive. That is 4.1 arc-seconds, equivalent to 0.0002" /10". They take a long time to settle.

The term "precision" here is a bit relative, not synonymous with "sensitivity", or "resolution". I am also thinking "quality".

We also have the 200mm Stiefelmayer Prazision here as a reference. It is a beautiful thing, and can be trusted.

On any flat surface, there is a line somewhere that is level, found by rotating the level on the surface. Of course, if the level itself is also out of adjustment, then rotating it 180° onto the same line does not work. It finds a new line. A line bisecting those is nearer the truth, so put it there, adjust the vial, and try again. You can converge on it in later stages by adjusting to move the bubble to split the difference when rotating 180, then trying again to find the line.

I took the short-cut, first using the Stiefelmayer to discover where was level. It would return to level when rotated 180°. The problem was, no amount of adjustment would let the Chinese level repeat the trick.

Wanyou #1 finds a different line nearby. Given it's shorter this could be some tiny thing in the paper thickness under it. I get it one should do this on the hard surface.

Wanyou #2 could not repeat the 180°trick. Why??

It was as if the adjust move also shifted or twisted something else inside, but 180°would not happen anywhere. It was time to take it apart!

Also, in passing the little cross level was always at the limit, whereas the Stiefelmayer was near middle, but getting that sorted is another issue.

-

-

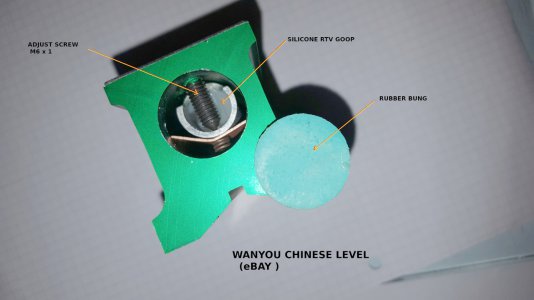

It's Aluminum!

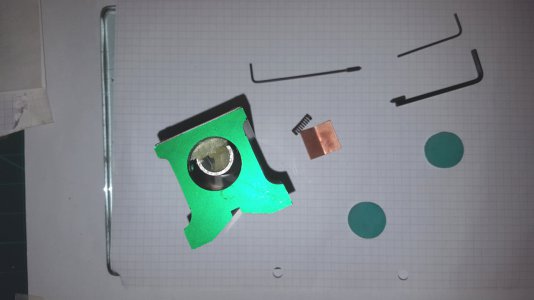

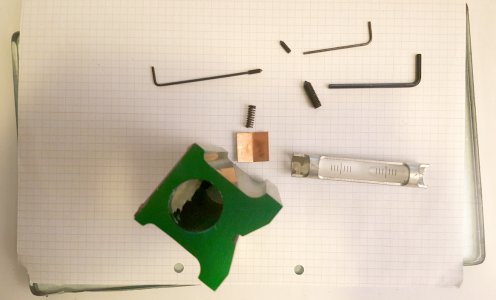

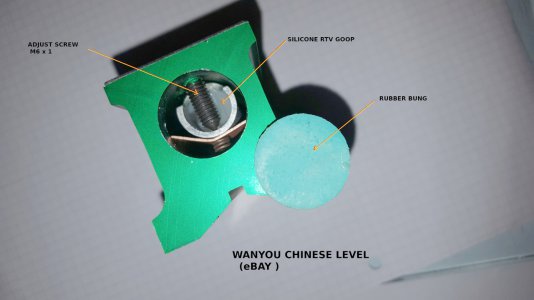

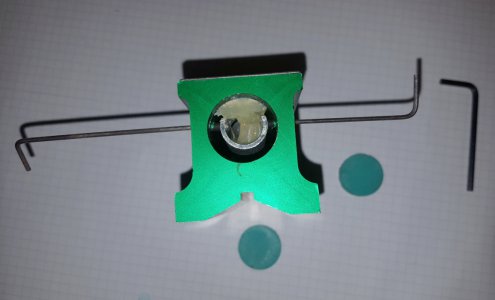

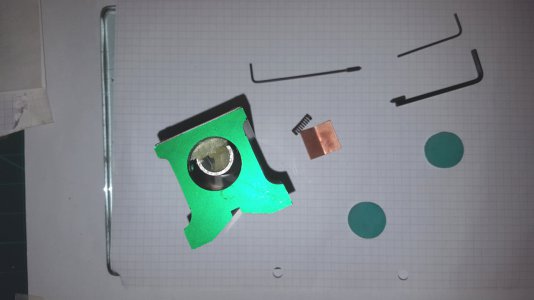

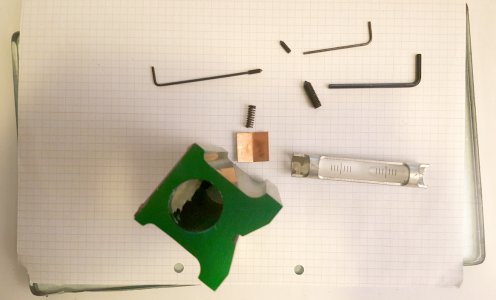

Yeah! At that price, don't expect anything else. If you want a practical working level ,choose precision ground hardened cast iron. So, given the total non-functionality of Wanyou #2, I started the strip-down, beginning by digging out the blue rubber bungs on the ends.

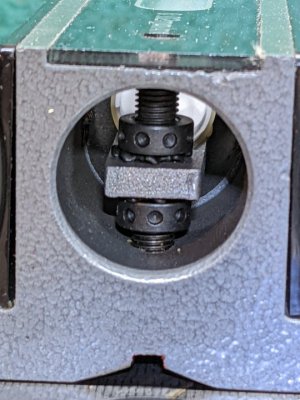

One end is (kind of) hinged.

From each side is a little black hex set-screw, with a pointed end that finds it's corresponding hole in the aluminum tube that holds the vial glass. The glass is set into the tube by silicone RTV. The same goop holds the tiny cross-level vial in place. The RTV had met such that the tube hung there, even after I took the screws out. This is supposed to be a metric thing, but the only allen wrenches I that fitted measured as 1/16" AF

_

_

Is it OK for me?

I suppose I could hang it back together with some "improvements", and use as a part for the Kingway. For use as a level to directly measure the ups and downs along a straight edge, or machine way - not really! I am cheapskate enough to try, but I do have the Stiefelmayer.

Just notice the big burr where the drill for the pivots went through. The fat burr probably better suits the screw point anyway. I suppose, Chinese style, if it's in a place nobody can see, then don't make it pretty.

So there you have it!

A Starret, or Stiefelmayer, or similar is freaky expensive for a level. You can refurbish a good used Starret, make sure there are no dings where it matters, and do a self-calibration. For the price, something like this I can find useful in my way, as a project part source. I know what it is, and what it does. Even so, the goopy bits and internals would be nothing to write home about!

Here we have a take-apart of probably one of the cheapest levels available via eBay.

I have two of them, and I only wanted them as a source of sensitive level vials I could fix onto (my version) homebrew Kingway tool.

I thought that things might go easier if one could have them with the vials already mounted into something that could easily clamp/fix onto a Kingway crossbar.

They have an "adjustment screw", so we at least have a little try-out. It did not go well!

The self-calibration recipe(s) are well known. Start with you assume the level is wrong, and also, your level surface isn't (level). Throw in that it needs to be flat (enough) and stiff (enough). Done on a 3/8" thick plate glass on the green cutting mat, on the desk, it can see a deflection from a smartphone being placed on the desk to the side. The 0.02mm/m choice is probably too sensitive. That is 4.1 arc-seconds, equivalent to 0.0002" /10". They take a long time to settle.

The term "precision" here is a bit relative, not synonymous with "sensitivity", or "resolution". I am also thinking "quality".

We also have the 200mm Stiefelmayer Prazision here as a reference. It is a beautiful thing, and can be trusted.

On any flat surface, there is a line somewhere that is level, found by rotating the level on the surface. Of course, if the level itself is also out of adjustment, then rotating it 180° onto the same line does not work. It finds a new line. A line bisecting those is nearer the truth, so put it there, adjust the vial, and try again. You can converge on it in later stages by adjusting to move the bubble to split the difference when rotating 180, then trying again to find the line.

I took the short-cut, first using the Stiefelmayer to discover where was level. It would return to level when rotated 180°. The problem was, no amount of adjustment would let the Chinese level repeat the trick.

Wanyou #1 finds a different line nearby. Given it's shorter this could be some tiny thing in the paper thickness under it. I get it one should do this on the hard surface.

Wanyou #2 could not repeat the 180°trick. Why??

It was as if the adjust move also shifted or twisted something else inside, but 180°would not happen anywhere. It was time to take it apart!

Also, in passing the little cross level was always at the limit, whereas the Stiefelmayer was near middle, but getting that sorted is another issue.

-

-

It's Aluminum!

Yeah! At that price, don't expect anything else. If you want a practical working level ,choose precision ground hardened cast iron. So, given the total non-functionality of Wanyou #2, I started the strip-down, beginning by digging out the blue rubber bungs on the ends.

One end is (kind of) hinged.

From each side is a little black hex set-screw, with a pointed end that finds it's corresponding hole in the aluminum tube that holds the vial glass. The glass is set into the tube by silicone RTV. The same goop holds the tiny cross-level vial in place. The RTV had met such that the tube hung there, even after I took the screws out. This is supposed to be a metric thing, but the only allen wrenches I that fitted measured as 1/16" AF

_

_

Is it OK for me?

I suppose I could hang it back together with some "improvements", and use as a part for the Kingway. For use as a level to directly measure the ups and downs along a straight edge, or machine way - not really! I am cheapskate enough to try, but I do have the Stiefelmayer.

Just notice the big burr where the drill for the pivots went through. The fat burr probably better suits the screw point anyway. I suppose, Chinese style, if it's in a place nobody can see, then don't make it pretty.

So there you have it!

A Starret, or Stiefelmayer, or similar is freaky expensive for a level. You can refurbish a good used Starret, make sure there are no dings where it matters, and do a self-calibration. For the price, something like this I can find useful in my way, as a project part source. I know what it is, and what it does. Even so, the goopy bits and internals would be nothing to write home about!

Last edited: