I ordered a cheap carbide tipped boring bar set from Shars. I ordered the 5/8' Shank. I needed to use one to bore out a pulley center. I unboxed my AXA boring bar holder and the hole is way too big for the boring bars. I didn't measure the shank yet to see how big they really are.

I had to get this done so I installed one in one of the tool bit holders and used it with great success.

Can I get a different bushing or do I have to buy different boring bars? I don't want to keep using them in a tool holder designed for square tool bits.

This was my first boring project and I needed it done to fix a tool to get a job done. I can't believe how well it worked even though it ws the wrong way to do this. The pulley center had a keyway which made me nervous. I took very light cuts and measured often until it was the right size.

I don't want to create a habit of doing things wrong as a beginner but this did keep 3 men working for the rest of the week.

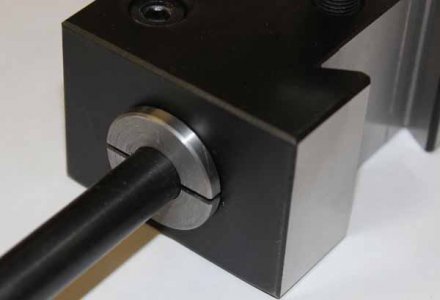

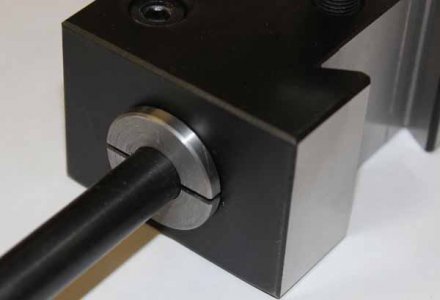

Not the wrong way at all, many quick change tool blocks have V-grooves just for this purpose, along with holding drill bits.

I run an old CNC lathe with a QCTP nearly every day, 12+ tool blocks 5 of which hold boring bars and internal grooving tools in V-grooves, I do have a round tool block with a 1 1/2" diameter bore only because the other blocks will not fit a round shank of bigger then 1" or so.

For small boring bars less then 1/2" I drill and ream a square piece of material, drill and tap some set screw holes, insert the round shank in it and clamp it in a square tool block, this is nearly a requirement with round tooling 1/4" and less in this situation.

Remember that the only wrong method is one that does not work, the correct method is the one that works.

I made 53 of these very supremely annoying small parts today, .135" reamed bore, .236" OD X .014" step, .079" overall length with a .375" OD from 304, I was only required to make 40 but droped a dozen in the chip tray, the part to part time was a bit under 4 minutes so I just made more to make up for the lost ones, an operation using flood coolant makes them slippery little buggers to handle.

free upload image

free upload image