- Joined

- Oct 31, 2016

- Messages

- 2,720

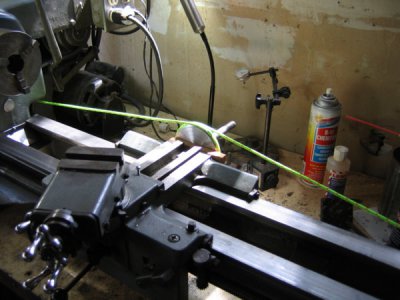

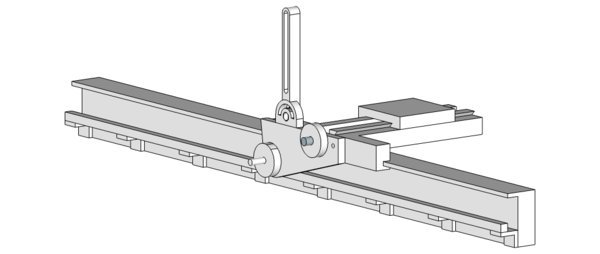

Getting started with this project. The coupler nut arrived Friday while I was out of town. Today I found some aluminum and steel flat stock in my scrap bin. Any preference in using aluminum or steel for the end plate?

I have thought of another way to lock the shaft into the coupler nut. The coupler nut is 1/2 x 10 tpi LH acme. I thought about tapping half of the coupler nut with 1/2 x 13 RH standard thread. I would think that this would lock the coupler to the lead screw and the shaft when I tighten the shaft against the lead screw and having opposing threading would keep everything locked together. Is this a dumb idea?

I am still trying to figure out the math to calculate the diameter of the wheel. Info I found and posted above used a 10 tpi lead screw as an example but didn't include any of the actual math. The original article probably included the math. I have not found a copy online that I could study. The cross slide lead screw on my lathe is also 10 tpi. I have tried to back into his answer and the only thing I come up with is that he multiplied the taper per foot by 10. This seems too simplistic to me. I might have to make a wheel and measure how far the cross slide moves in one foot. Can anybody help me out with this?

I have thought of another way to lock the shaft into the coupler nut. The coupler nut is 1/2 x 10 tpi LH acme. I thought about tapping half of the coupler nut with 1/2 x 13 RH standard thread. I would think that this would lock the coupler to the lead screw and the shaft when I tighten the shaft against the lead screw and having opposing threading would keep everything locked together. Is this a dumb idea?

I am still trying to figure out the math to calculate the diameter of the wheel. Info I found and posted above used a 10 tpi lead screw as an example but didn't include any of the actual math. The original article probably included the math. I have not found a copy online that I could study. The cross slide lead screw on my lathe is also 10 tpi. I have tried to back into his answer and the only thing I come up with is that he multiplied the taper per foot by 10. This seems too simplistic to me. I might have to make a wheel and measure how far the cross slide moves in one foot. Can anybody help me out with this?

Last edited: