There has been a lot of great information shared already so forgive me if this is repetitive. I tried to keep this brief but it is tough.

A couple of notes on successful grinding starting from the beginning.

- The machine must be leveled to a very high sensitivity.

- A .0005"/foot or better level is required.

- The machine table should be inspected for flatness before mounting the chuck

- The table can be ground if it is not within .0002" flatness over the chuck mounting area.

- The chuck must be inspected for flatness/parallelism before mounting.

- If the bottom is not flat, it should be blocked in, top side down and ground flat.

- Blocking it in and shimming any twist/warp will keep from reproducing the same defect.

- Do not use the magnet or clamp to hold it it down.

- Mount the chuck..

- Assemble the rail in order to indicate in straight in the x axis direction

- clamp the chuck, 15 foot pounds on the left and 10 foot pounds on the right.

- This is to allow for heat expansion.

- Magnet on or magnet off?

- Permanent magnets, always on.

- They do not create heat when on.

- Electromagnetic chucks turned on with power reduced to below 30% or off

- They will create heat and the reduced power helps

- Never leave them on at full power for long periods unless you have flood coolant running.

- Electro permanent chucks

- Perform just like Permanent magnetic chucks

- Grinding the chuck (top, bottom or table)

- A course dress is recommended

- Down feed should not exceed .0002"-.0003" (Y-axis)

- Cross feed should be about .050" to .100" per stroke (Z-axis)

- Traverse speed (X-axis) should be fairly rapid

- You will want to do several spark outs

- If you have coolant, use it!

- smearing wax on the chuck between cuts works

- Smearing cutting oil on the chuck between cuts works as well or better.

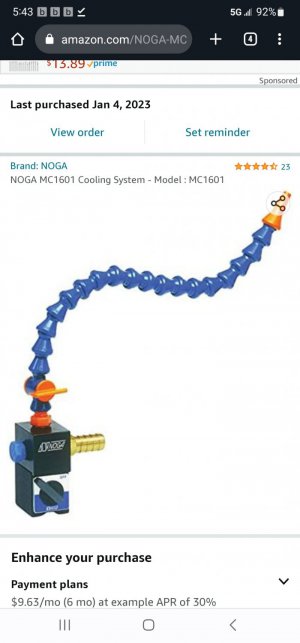

- Mist coolant works better and flood coolant is best.

- With care, a chuck can be ground dry. Leave electromagnetic chucks off and wait for the surface to cool to ambient between cuts.

I attached some information about wheel selection and dressing. I put this together many years ago so there may be some outdated terminology. If you have any questions, do not hesitate to ask.