What is wrong with a Dremel or other grinder? They remove too much in concentrated spots and way too fast.

It is good you have lots to time, because it takes a lot of time....

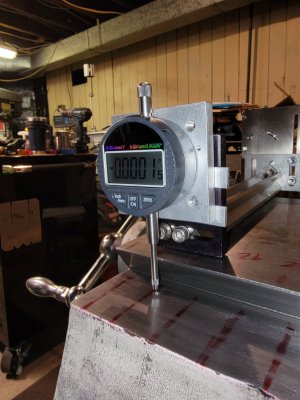

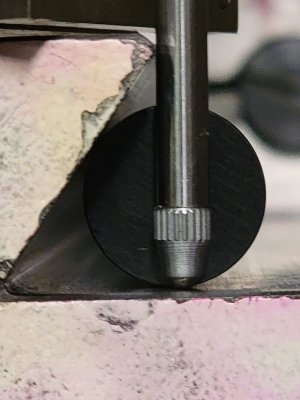

I have had a similar problem with my mill ways and I have been fixing it .... slowly.... not by scraping or to grinding, but by sanding. Use good water proof emery cloth. The way you describe thinks your desire is to remove 0.005" along the non-dipped rest of the way to bring it down to the dip. I have not attempted to take this out of the v-groove only the flat part of the way where the saddle rests and runs. Yes, my machine has hardened ways too, but you would be impressed at how fast it actually comes off. You are correct, the way to achieve this is to have a good measurement tool. Don't start until you figure this part out. In the case of my Mill I have a reference surface to work from. So I use a flat bar that rests on the reference surface and then use digital dial indicator (plunge style) gauge to measure the distance to the flat part of the way along the length of the way by sliding my flat bar along. The dial indicators yield quite accurate results. I can measure deviations on the few micron scale repeatedly! You also have to measure across the flat part, not just down the length. You want to keep it flat in both directions. I have also built a tool that does something similar, but measures the depth of the V groove, actually the distance between the two V grooves, between the two sides of the saddle. However, I have yet to try it out.

Patience is critical. Go slow with more time spent in measuring than in actual sanding.

Which part of your way dips? The flat part or the V? If it is the flat part you stand a chance. I would not try the V surfaces without an even more complex measuring tool. Check the tops of your Vs are they flat? If so you might use them as reference surfaces.

I found that these digital depth micrometers are quite accurate and very repeatable. Most importantly, they are affordable. They also sell a digital cable that will suck the reading right into Excel or Word at the click of a button. So you do not have to write it all down by hand. Clockwise Tools. If you think you want to go this route check out the micrometers and the cable... links below.

"Clockwise Tools Digital Indicator, DITR-0105 0-1 Inch/25.4mm, 0.00005 Inch/0.001mm Resolution, Inch/Metric Conversion, Auto Off" Amazon at $64. I have two so I can measure both sides of my ways at the same time.

Get the high accuracy 1" stroke version. There is one with auto off and one without. Your choice. It takes a 3V li-ion cell.

Get the high accuracy 1" stroke version. There is one with auto off and one without. Your choice. It takes a 3V li-ion cell.

You will also find the cable at their store or via these links:

It is good you have lots to time, because it takes a lot of time....

I have had a similar problem with my mill ways and I have been fixing it .... slowly.... not by scraping or to grinding, but by sanding. Use good water proof emery cloth. The way you describe thinks your desire is to remove 0.005" along the non-dipped rest of the way to bring it down to the dip. I have not attempted to take this out of the v-groove only the flat part of the way where the saddle rests and runs. Yes, my machine has hardened ways too, but you would be impressed at how fast it actually comes off. You are correct, the way to achieve this is to have a good measurement tool. Don't start until you figure this part out. In the case of my Mill I have a reference surface to work from. So I use a flat bar that rests on the reference surface and then use digital dial indicator (plunge style) gauge to measure the distance to the flat part of the way along the length of the way by sliding my flat bar along. The dial indicators yield quite accurate results. I can measure deviations on the few micron scale repeatedly! You also have to measure across the flat part, not just down the length. You want to keep it flat in both directions. I have also built a tool that does something similar, but measures the depth of the V groove, actually the distance between the two V grooves, between the two sides of the saddle. However, I have yet to try it out.

Patience is critical. Go slow with more time spent in measuring than in actual sanding.

Which part of your way dips? The flat part or the V? If it is the flat part you stand a chance. I would not try the V surfaces without an even more complex measuring tool. Check the tops of your Vs are they flat? If so you might use them as reference surfaces.

I found that these digital depth micrometers are quite accurate and very repeatable. Most importantly, they are affordable. They also sell a digital cable that will suck the reading right into Excel or Word at the click of a button. So you do not have to write it all down by hand. Clockwise Tools. If you think you want to go this route check out the micrometers and the cable... links below.

"Clockwise Tools Digital Indicator, DITR-0105 0-1 Inch/25.4mm, 0.00005 Inch/0.001mm Resolution, Inch/Metric Conversion, Auto Off" Amazon at $64. I have two so I can measure both sides of my ways at the same time.

Clockwise Tools

Clockwise Tools company is a carrier that provides a diverse selection of high cost performance tools, home appliances, and other accessories. We have Clockwise Tools and VINCA two brands that offer quality products aim at meeting the needs of both professional and home DIY market demands. We...

www.amazon.com

You will also find the cable at their store or via these links: