I found another lathe on market place this week I may go take a look at I'd like some more experienced opinions on if possible.

www.facebook.com

www.facebook.com

I've realized the biggest things I want in a lathe are at least 10" of swing that's probably the absolute maximum diameter of a piece I'd be working on it (and that would be too often) and then the ability to cut thread. Looking at the link posted above it meets one requirement but I'm unsure about the thread cutting ability. I understand there is normally an attachment on the cross slide that can show you when to engage the half nut? I'm not sure I see anything like that on the craftsman but I'm also not particularly familiar with these machines.

As always thank you all for your wealth of knowledge.

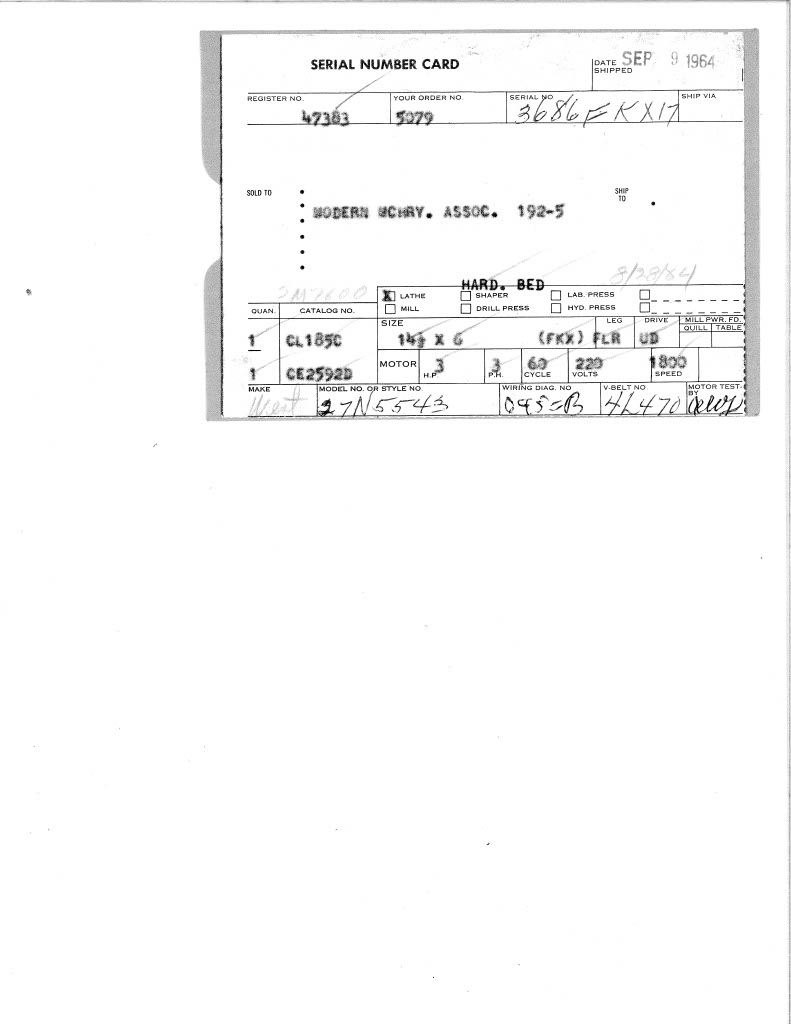

Additionally I found a little more information about the south bend I posted last weekend. The seller was kind enough to provide the serial number for the lathe and I paid the $25 to grizzly for the card.

Based on this I am led to believe the lathe has hardened ways? I understand a lot of people seem to prefer hardened ways and it became a more common option in lathes as they matured into the second half of the 1900's. Is there any additional considerations with hardened ways I should keep my eye out for when looking at the machine tomorrow?

Log into Facebook

Log into Facebook to start sharing and connecting with your friends, family, and people you know.

www.facebook.com

www.facebook.com

I've realized the biggest things I want in a lathe are at least 10" of swing that's probably the absolute maximum diameter of a piece I'd be working on it (and that would be too often) and then the ability to cut thread. Looking at the link posted above it meets one requirement but I'm unsure about the thread cutting ability. I understand there is normally an attachment on the cross slide that can show you when to engage the half nut? I'm not sure I see anything like that on the craftsman but I'm also not particularly familiar with these machines.

As always thank you all for your wealth of knowledge.

Additionally I found a little more information about the south bend I posted last weekend. The seller was kind enough to provide the serial number for the lathe and I paid the $25 to grizzly for the card.

Based on this I am led to believe the lathe has hardened ways? I understand a lot of people seem to prefer hardened ways and it became a more common option in lathes as they matured into the second half of the 1900's. Is there any additional considerations with hardened ways I should keep my eye out for when looking at the machine tomorrow?

Last edited: