-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Spindle Goop

- Thread starter NegativeK

- Start date

- Joined

- Dec 23, 2019

- Messages

- 1,138

Ewww. It should not be a sealed bearing up there. The oilers are set up to wick onto a felt washer, which then drip feeds the top bearing and spindle bearings as the oil runs down. Pull the top of the head off and have a good look in there too, it could well be full of nasty schmoo. I doubt it's done much damage, though it's worth assessing whether the spindle bearings are holding up ok with lack of lube. If the shim tube between the outer races can be moved sideways easily, they're toast.

- Joined

- Dec 23, 2019

- Messages

- 1,138

Problem with running grease is there's no way to replenish it or run sealed bearings of the correct type in the Bridgeport spindle. I suspect the emulsion is due to condensation mixing in. That sealed bearing has created quite the trap.

- Joined

- Jan 6, 2017

- Messages

- 1,248

Those sealed bearings are designed for grease, but only for the grease that comes pre-packed inside the seal. Not that red stuff everywhere.

As Lo-Fi pointed out, there shouldn't be sealed bearings in there.

Milling machines of that type typically come with tapered roller bearings, or sometimes angular contact bearings.

Which begs the question, what type of bearings are those? Because the performance of a milling machine can be severely diminished by poor bearing selection.

If someone who had no idea what he was doing, replaced them with whatever was cheapest from Amazon, it would make for some pretty bad spindle performance.

The cheapest bearings available are typically p0 precision, c3 clearance deep groove radial ball bearings. Designed for radial loads only, and with "extra" clearance built into the rollers. Not good for the axial loads drilling produces. Not good for anything else spindle related either.

The OP should replace those with some P5 tapered rollers or Angular Contact bearings ASAP.

As Lo-Fi pointed out, there shouldn't be sealed bearings in there.

Milling machines of that type typically come with tapered roller bearings, or sometimes angular contact bearings.

Which begs the question, what type of bearings are those? Because the performance of a milling machine can be severely diminished by poor bearing selection.

If someone who had no idea what he was doing, replaced them with whatever was cheapest from Amazon, it would make for some pretty bad spindle performance.

The cheapest bearings available are typically p0 precision, c3 clearance deep groove radial ball bearings. Designed for radial loads only, and with "extra" clearance built into the rollers. Not good for the axial loads drilling produces. Not good for anything else spindle related either.

The OP should replace those with some P5 tapered rollers or Angular Contact bearings ASAP.

Last edited:

- Joined

- Jan 6, 2017

- Messages

- 1,248

Your Acra 2s appears to be the same basic machine as the Grizzly G0796. It has the same "M" on the column casting as the original Bridgeport model they copied, the same dual drains in the base casting, and lots of other indicators.

The grizzly manual shows it to use the common 7207 (35mmx72x17mm) angular contact bearing for both the upper and lower. the pulley carrier takes the 6206zz deep groove shielded radial bearing.

The cheapo sealed radial bearings in that 35x72x17 size are 6207. I wonder what the chances are, when you clean the grease off, those bearings say "6207-2rs c3" or similar

When you replace those, look for 7207 bearings with a 20ish degree contact angle and P5-P4 precision (abec5 to abec9) depending on your budget.

The grizzly manual shows it to use the common 7207 (35mmx72x17mm) angular contact bearing for both the upper and lower. the pulley carrier takes the 6206zz deep groove shielded radial bearing.

The cheapo sealed radial bearings in that 35x72x17 size are 6207. I wonder what the chances are, when you clean the grease off, those bearings say "6207-2rs c3" or similar

When you replace those, look for 7207 bearings with a 20ish degree contact angle and P5-P4 precision (abec5 to abec9) depending on your budget.

Okay, I've gotten some clarity on what's going on and what I'm going to do next. Brace for wall of text.

Re. the state of the machine, I'm in Vegas -- so no condensation or rain. The machine's also in very, very good condition otherwise. No detectable wear in the lead screw, and the two gibs I pulled looked like the scraping was untouched. I'm pretty certain the seller didn't bone me and the machine was very occasionally used -- just dirty from being in an auto shop.

For the bearings, they're NTN 7207C and NSK 6206V. I actually got a thumbs up from Tom Lipton on Acras (he has the variable speed model and has worked with other models,) so I'm not too concerned about being cheaped out by the builder. More importantly, the runout I measured before the spindle gooping was in the low tenths. And even if it's worse when under load, I'm going to keep using the ones I have until I'm unhappy with them, and then I'll just order from H&W. I'm hoping to avoid spending that money, but I'm comfortable installing them if necessary.

As for the plan going forward.. I've finally pieced together the puzzle. The upper bearing is shielded, and the lower bearings definitely had some grease in them -- so the assembler (I don't think it was anyone else; the nose cap had the set screw in the only drilled spot on the threads) went with grease, not oil. This also explains why the spindle oiling cup that's mentioned in the manual was replaced with a grease zerk, and the grease zerk explains the Nutella that's all over the top bearing. The oil that's visible is likely from me adding more than I should, in hopes that I'd flush out any tire dust that had accumulated.

So given all of that blather, I'm going to clean clean clean, repack the bearings, clean the inside of the quill, and be a lot more gentle with the two remaining oil spots. I also figure I'll need to pull apart the top housing and degunk what's in there, but that's for future me to deal with. I'm not super thrilled about pulling the motor off without help.

Re. the state of the machine, I'm in Vegas -- so no condensation or rain. The machine's also in very, very good condition otherwise. No detectable wear in the lead screw, and the two gibs I pulled looked like the scraping was untouched. I'm pretty certain the seller didn't bone me and the machine was very occasionally used -- just dirty from being in an auto shop.

For the bearings, they're NTN 7207C and NSK 6206V. I actually got a thumbs up from Tom Lipton on Acras (he has the variable speed model and has worked with other models,) so I'm not too concerned about being cheaped out by the builder. More importantly, the runout I measured before the spindle gooping was in the low tenths. And even if it's worse when under load, I'm going to keep using the ones I have until I'm unhappy with them, and then I'll just order from H&W. I'm hoping to avoid spending that money, but I'm comfortable installing them if necessary.

As for the plan going forward.. I've finally pieced together the puzzle. The upper bearing is shielded, and the lower bearings definitely had some grease in them -- so the assembler (I don't think it was anyone else; the nose cap had the set screw in the only drilled spot on the threads) went with grease, not oil. This also explains why the spindle oiling cup that's mentioned in the manual was replaced with a grease zerk, and the grease zerk explains the Nutella that's all over the top bearing. The oil that's visible is likely from me adding more than I should, in hopes that I'd flush out any tire dust that had accumulated.

So given all of that blather, I'm going to clean clean clean, repack the bearings, clean the inside of the quill, and be a lot more gentle with the two remaining oil spots. I also figure I'll need to pull apart the top housing and degunk what's in there, but that's for future me to deal with. I'm not super thrilled about pulling the motor off without help.

We're back!

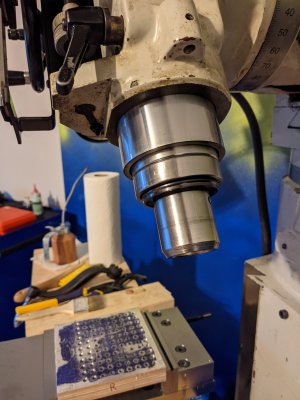

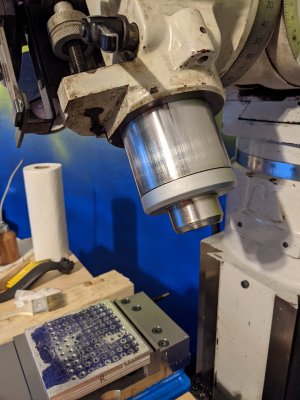

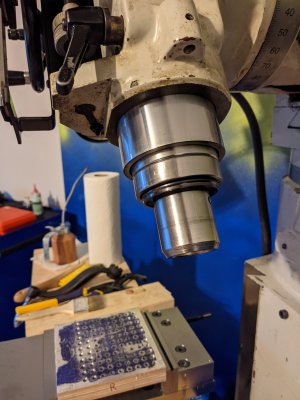

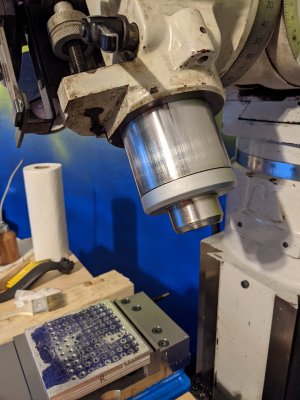

The grease arrived today, all the bearings are packed, and reassembly went smoothly. Runout in the taper is at 0.0003", which is maybe a tenth or two more than what it was. Maybe some day I'll regrind the taper, but I really don't feel the need now.

I'm somewhat proud of fixing the problem in only a few days, but really I'm just happy that I didn't make things notably worse.

The grease arrived today, all the bearings are packed, and reassembly went smoothly. Runout in the taper is at 0.0003", which is maybe a tenth or two more than what it was. Maybe some day I'll regrind the taper, but I really don't feel the need now.

I'm somewhat proud of fixing the problem in only a few days, but really I'm just happy that I didn't make things notably worse.

Last edited: