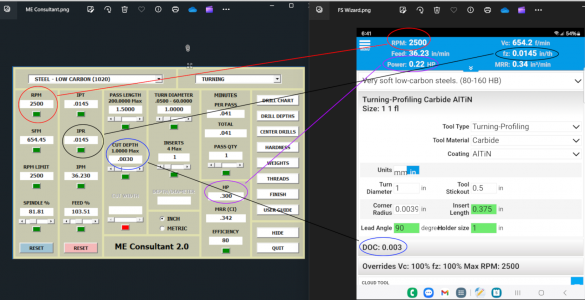

I fiddled with FS Wizard and ME Consultant, they both come up with more or less the same parameters, for turning a part.

Sandvick-Coromant's cutting tool is more detailed, and generally in agreement with the two mentioned above, but it has no provision for low-life machines like mine; once max rpm is lowered past their optimal, no solution is offered.

So speed and feed OK.

Depth of cut reflects in the horsepower needed to get the job done. I don't know if the 250w motor plate on the machine indicates input power, or output. In any event, both programs appear to assume the lathe has a lot of horsepower. I don't see a way to set horsepower as a constraint, so i have to back into it by fiddling with DOC.

Here's a pictogram:

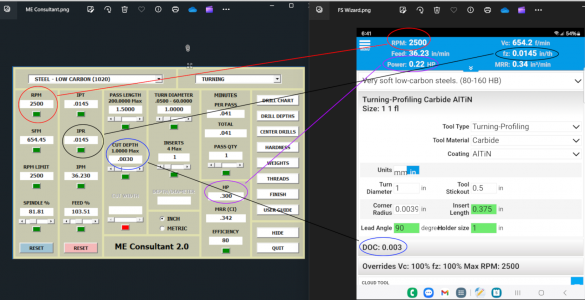

Sandvick-Coromant's cutting tool is more detailed, and generally in agreement with the two mentioned above, but it has no provision for low-life machines like mine; once max rpm is lowered past their optimal, no solution is offered.

So speed and feed OK.

Depth of cut reflects in the horsepower needed to get the job done. I don't know if the 250w motor plate on the machine indicates input power, or output. In any event, both programs appear to assume the lathe has a lot of horsepower. I don't see a way to set horsepower as a constraint, so i have to back into it by fiddling with DOC.

Here's a pictogram: