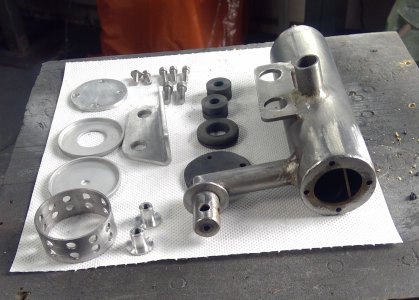

So, I finally settled on a catch can design and built it. The first one was simply too big, creating mounting problems, so that was binned. The final one is made of 42mm tube with four baffles. Instead of welding the baffles inside of the tube, I fixed them together with a 4mm screwed and peened the end so it wouldn’t come apart, the baffle cartridge was then pressed into place resting on top of the intake tube so it won’t float around. The intake tube stretches across the diameter of the 42mm tube and has three exit holes underneath. For the blowby gas to escape it has to exit via the four baffles and finally through some stainless mesh before exiting through the air filter on top, set between the two carb filters.

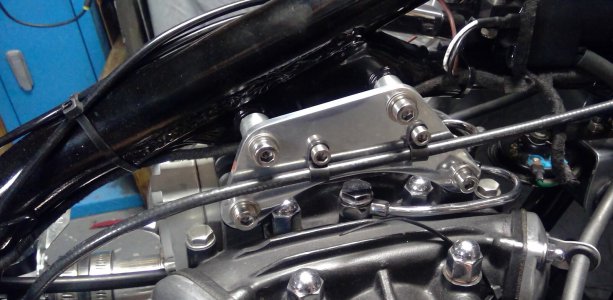

I’ve gone with a remote empty point via a tap connected to the catch can by a rubber hose. The filtering medium inside the can is replaceable via the top plate secured on top by four 4mm stainless allens. The can is mounted to an aluminium bracket by two rubber gromets and two threaded T nuts to stop the gromet from being squished too far, then fixed to the right, rear engine bracket.

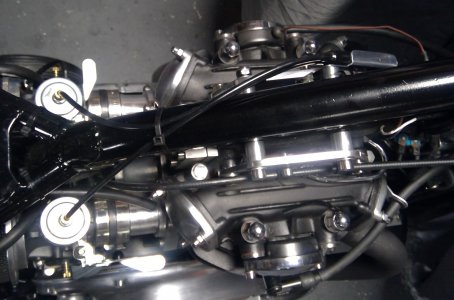

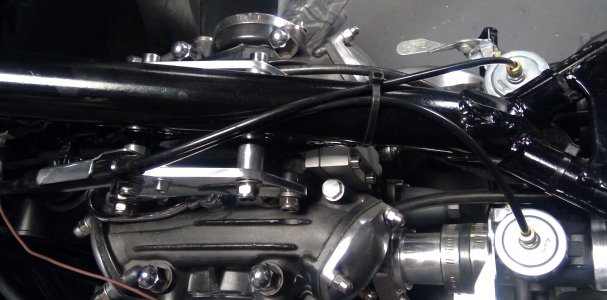

Mounting the can proved a little troublesome: behind the motor over top of the swing arm pivot is the only place I could find to mount it. To make it less noticeable I painted it black and welded an outlet on the side so I could mount the final filter between the two carb filters. It is only a small catch can with around 220ml capacity, that’s in total of course, realistically only around 100mm under the baffles. If it proves too small, I can fit a larger container under the swingarm connected to the catch can outlet by a rubber hose.

It’s very busy in this are area now, two carbs, three filters, catch can, fuel distributor block, making it a little difficult to remove the air filter caps.