- Joined

- Sep 22, 2018

- Messages

- 23

@bill stupak i felt the conventional cut was beating the machine up much more than the climb cut. After touching up the end mill on a stone and using a different piece of stock, I was getting much better conventional cutting performance (0.020") than before and the climb was good too.

@WCraig work being held by a 4" grizzly milling vise. Piece is secure in the vice and vice is secure to table.

@macardoso that's a distinct possibility regarding material variability. The second piece milled much easier. I'm impressed by your previous post. It's good to know this machine can do more. You said DOC was .125". What was WOC?

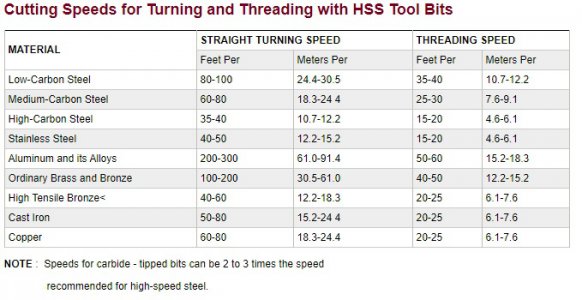

I'll double check my table. I'm guessing my problem is/was a dull end mill and too large of a diameter.

@WCraig work being held by a 4" grizzly milling vise. Piece is secure in the vice and vice is secure to table.

@macardoso that's a distinct possibility regarding material variability. The second piece milled much easier. I'm impressed by your previous post. It's good to know this machine can do more. You said DOC was .125". What was WOC?

I'll double check my table. I'm guessing my problem is/was a dull end mill and too large of a diameter.