- Joined

- Sep 22, 2018

- Messages

- 23

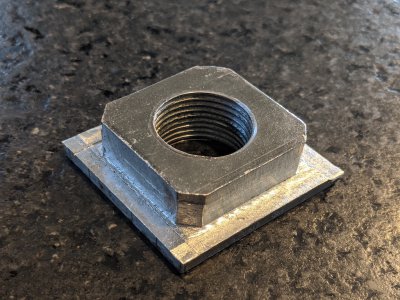

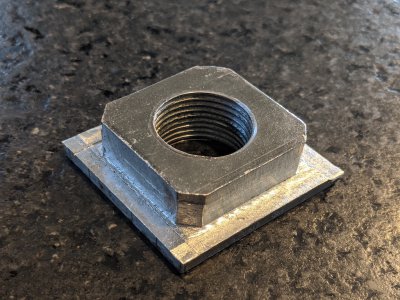

I have a small mill, G0704, and am wondering what this machine can reasonably do when milling steel. The picture below shows an endcap for 2" square tubing with 0.25" wall thickness. The stock is 3/4" x 2" flat bar steel cut into a 2" square piece. I needed to remove approximately 0.25" on the 4 sides and 0.5" deep. I was going to mill out that perimeter area and quickly found that it was going to take a lot of passes to achieve that. I ended up roughing out the recess area with a bandsaw and then finishing out to final dimensions using the mill. Even with the roughing process it took quite a bit of time.

So the point to my post. What are reasonable expectations when milling steel on this machine?

I was using a 2 flute, 1/2" diameter HSS end mill running at 1200 RPM. I find that i'm only able to take off a few thousandths (0.003") per pass. Conventional milling is hard on the machine, lots of noise and chatter, even with the lightest of cuts and climbing cuts seem to be easier and less jolting but well aware of what could happen with too deep of a cut.

Is that DOC all that I can reasonably expect from this machine?

So the point to my post. What are reasonable expectations when milling steel on this machine?

I was using a 2 flute, 1/2" diameter HSS end mill running at 1200 RPM. I find that i'm only able to take off a few thousandths (0.003") per pass. Conventional milling is hard on the machine, lots of noise and chatter, even with the lightest of cuts and climbing cuts seem to be easier and less jolting but well aware of what could happen with too deep of a cut.

Is that DOC all that I can reasonably expect from this machine?