How close do you need to get to the shoulder? Does the part require no thread relief between the thread & shoulder? With practice you should be able to get it. I can thread into a 1/16" wide thread relief no problem disengaging the half nut without any aid.

By aid what I mean is a dial indicator. When I single point threads I set up a dial indicator to read zero 10 thou off a shoulder or blind hole. I use the modified flank method for threading so to set the dial indicator after setting tool position off the work, I retract the cross slide, advance the compound to the full depth required for the thread pitch being cut, then move the carriage so the cutter bottoms out on the shoulder or the blind hole. Then I set the dial indicator for the carriage +.010. I set the 0 mark at 12:00, the needle starts moving from 6:00 on my DI.

I'm certainly not a pro or even close but I'm able to disengage at 0 on the dial indicator pretty consistently or within a few thou. So in theory I could probably get even close than 10 thou but I never have a need to get that close & to play it safe. Sometimes I thread with no thread relief at all using this method. I know I'm not the only one that uses a dial indicator for threading. Although I have a DRO now, a digital display is pretty much useless for the Z axis for threading.

Threading from headstock to the tailstock is great & allows you to run higher spindle speeds than you normally would & should give you a better surface finish but there are downsides too. Pretty much always need a thread relief which most people use anyway (stronger with no thread relief). But if threading a very coarse pitch the thread dial will be moving pretty fast. There is no room for error engaging the half nut on a specific mark when needed. At least with threading conventionally from right to left you do have room for error & can reset with no damage if you miss your mark. But this shouldn't be an issue once you are used to it. If you are threading a metric thread & you have an imperial lathe (or vice versa) you can't use the half nut here & if the thread is up to a shoulder or a blind hole, getting your carriage lined up for the next thread will be tricky. On top of all that you'll need LH tools. Not knocking the method, just saying it's not for everyone.

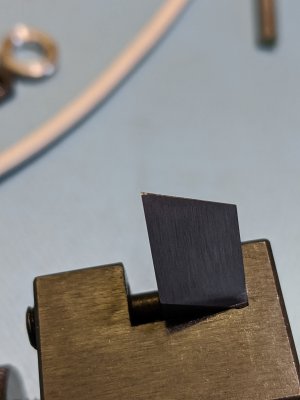

View attachment 316720

No thread relief

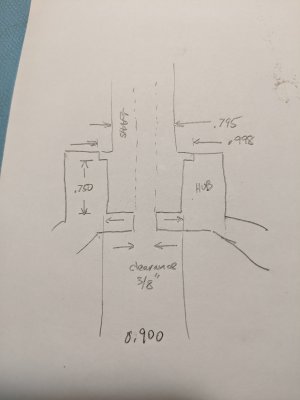

View attachment 316721

, holding the handwheel was easy. All it took was a night's sleep to figure it out. Switched jaws on the 3J chuck and opened the jaws. The wheel's not quite running true, but it's ok. It was true on initial clamping, but it shifted when I tightened (actually loosened) the jaws. Slight vibration when running. Not quite enough vibration to make me want to balance it.

, holding the handwheel was easy. All it took was a night's sleep to figure it out. Switched jaws on the 3J chuck and opened the jaws. The wheel's not quite running true, but it's ok. It was true on initial clamping, but it shifted when I tightened (actually loosened) the jaws. Slight vibration when running. Not quite enough vibration to make me want to balance it.