We got a lot more done this weekend on the mill. The table is back on and the oiling problem for the lead screw is taken care of. There was one metering valve in the valve block in the saddle with nothing connected to it and no way to oil the ball screw. I used some brake cleaner and got the valve unplugged and used some 1/8" copper tubing and made up a drip line that oils the screw. Jim looked at the PDF's of the factory manual JimS sent us said that's the way it was done from the factory, but for the life of me I can't understand why anyone would take it off and leave the screw un-lubricated. When I went to put the X axis motor back on I found some slop in the keyway on the ball screw. It would cause backlash so has to be taken care of. Tried drilling the flexible coupler it to put some set screws in to lock it to the shaft, but the coupler is hardened so that didn't work out. I found a new stainless one on fleabay and ordered it today.

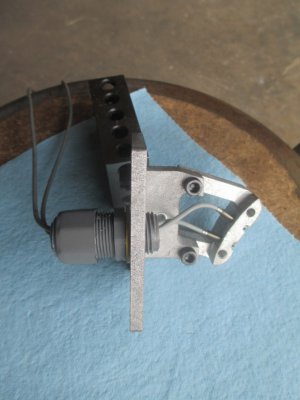

We got the spindle motor back on with quite a bit of work. Used some all thread and compressed the spring on the motor pulley so we could drop it in place easier. Jim made a spacer up that held the pulleys apart and we just used pry bars to pop it off after the motor was in place. We used Jim's forklift to lift the motor to put in in place. ( EDIT: Pic added by Jim)

Now a rant about Home Depot's 1/2" all thread. Drove 10 miles to get the rod (my second trip yesterday to Home Depot, went there instead of Ace because Harbor Fright is just a few blocks away and we needed a bearing spreader) and got back to Jim's and the rod was covered in such a thick galvanized coating that the nuts couldn't be screwed on. I tried chasing the threads with a die and no dice. What a royal pain, had to make a trip ( my second one yesterday) to Ace hardware for another piece of rod. Needles to say I'm not real high on Home Depot's quality control right now. Cost us precious time and me money.

After we got the motor on I wired up the VFD to the motor. Powered it up and Jim couldn't get the motor it to turn on. So we gave up for the day about 8 last night. Today Jim told me today he found a loose connection on the buss bar (amazingly it isn't something I did) and now the spindle is in his words " spindling"

I've made a number of "errors" wiring things up and thankfully Jim had the patience to fix them.

No much more left to do now. Jim has a lot of programming to do, and I need to get a 3 way valve on for the mist coolant, ordered it today along with a few other parts from Automation Direct. We also need to get the power draw bar on and wired up and connected to air valve, and the K axis reader head on and wired in and get the X axis ball motor connector on when it comes in, and get the stepper motor on for the speed changer.

I'm sure I'm forgetting something but we will take care of it when it comes up. Jim said we may be making some ships next weekend, that's if all the parts come in.

Today I scored a 1954 Craftsman drill press for $50.

http://www.hobby-machinist.com/threads/picked-up-a-craftsman-drill-press-today.37782/#post-323118

As I said in the thread on the way home with it I told my girlfriend I now have a project to work on at home. She said you need a home project? You work four 10's and spend 2 days a week at Jim's working on your mill and you need a project for your only day off at home? I just laughed.

I don't sit still with nothing to do very well at all even on my "only" day off. She has never been with someone like me before