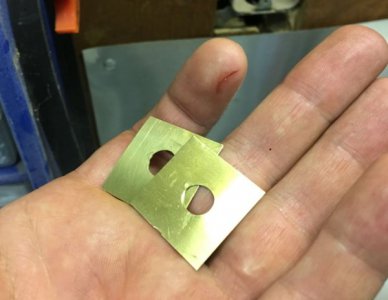

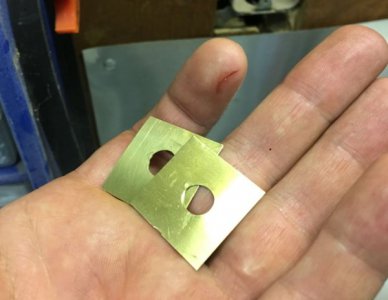

So pro-tip, when you are thinking in your head "if I do this, guaranteed it's gonna cut me" - stop! It was almost comedic, how the next second I was all "yuuuuup, that cut me". Pro-tip #2 -

drilling brass shims using standard drills is very dumb. I made the critical error of thinking "it's so thin, that brass grabbing thing shouldn't matter". Haha! Pro-tip #3 Don't hold sharp tiny stuff you are about to drill with your bare hands.

It's kind of miraculous I have made it this far in life, honestly.

I also discovered that I truly don't understand how shimming works (it almost seemed like "do the opposite of what your indicator says"), but in the end it only took me about 45 minutes.

Further, the brass shim stock I got seemed to influence readings dramatically more than their advertised size values. For example, X-axis was 0 on the left, +15 on the right. (in the end) I

added a 5-thou shim on the right to bring it to +1.5. The Y-axis was 0 at the front, +8 at the back. I added a 3-thou shim to the back to bring it to +1. I have to assume the shim stock was good, but my understanding of shimming was not.

(

maybe I needed to accommodate for where I was shimming, and the difference it would make farther out? i.e. needs maths?)

The good news, though...

- The mill is trammed in! Only out about 1.5 thou across the X-axis, and <1 thou across the Y-axis.

- The old Palmgren vise I had "accidentally" lying around is working great, although the jaws have seen better days - another project for another day...

- Took some long cuts in scrap mild steel, not feeling the same ridge between cuts from before! \o/

Shimming adventure

Decided against drilling...also, mark the thickness!

Decided against drilling...also, mark the thickness!

OWWWWW that was dumb

OWWWWW that was dumb

Brass & normal drill angles yo

Brass & normal drill angles yo

New-old vise!

With proper (?) usage of strap clamps!

New-old vise!

With proper (?) usage of strap clamps!

Thanks again, everyone!