I picked up a new Sherline lathe and mill to get into machining, so far the mill has been great however I'm running into some issues with the cross slide on the lathe and can't figure out if I've not setup the machine correctly or if there's something else going on.

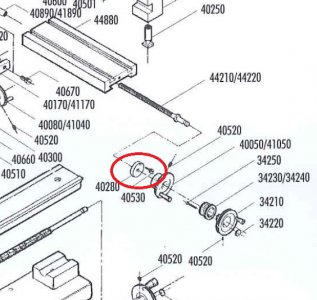

For the first 50% of travel the cross slide feels fine and just like other handwheels, however at about 50% I start getting some binding that increases to the point where I can't turn the the handwheel anymore. The binding is at a specific rotation of the handwheel(i.e. the first 50% of the turn is normal and second 50% requires increased force). I've removed/rethreaded it multiple times, adjusted the gib, backlash screw and made sure all surfaces are properly lubricated. Having the gib looser gives me a larger range I can "use" but then the cross slide has more play in it than I think it probably should(and it still starts binding).

I've got a query out to Sherline but anything else I should consider or do I just have a bad cross slide?

For the first 50% of travel the cross slide feels fine and just like other handwheels, however at about 50% I start getting some binding that increases to the point where I can't turn the the handwheel anymore. The binding is at a specific rotation of the handwheel(i.e. the first 50% of the turn is normal and second 50% requires increased force). I've removed/rethreaded it multiple times, adjusted the gib, backlash screw and made sure all surfaces are properly lubricated. Having the gib looser gives me a larger range I can "use" but then the cross slide has more play in it than I think it probably should(and it still starts binding).

I've got a query out to Sherline but anything else I should consider or do I just have a bad cross slide?