- Joined

- Feb 15, 2020

- Messages

- 399

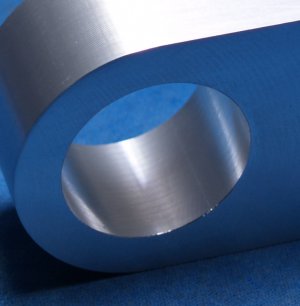

I had read in other posts here that Sherline's boring head is not a very good tool. I've used mine a few times now and I can say you can get good results with it, but it needs help out of the box.

The first two holes I bored with mine I did get good results, probably from my ignorance, but I noticed I could rock the tool around where the top and bottom of the head clamp together. Also with the clamp screw tight there was a visible gap between the top and bottom parts of the head. Not knowing any better I figured that's just the way it's designed.

The next hole I tried I couldn't get anything to go right, so I decided to figure out what was going on.

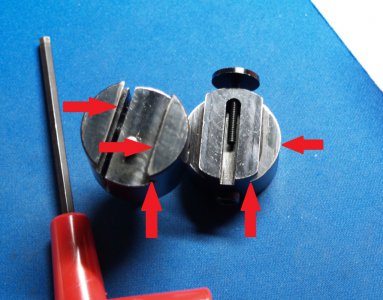

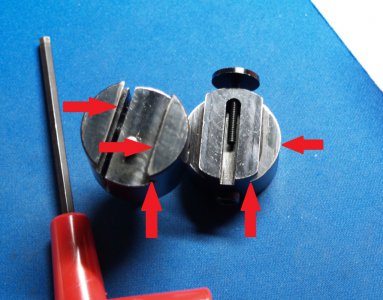

What I found was the hardened steel pin that the end of the adjusting screw bears upon, that Sherline calls the Gear Drive Pin, was making contact with the bottom half of the head when the clamp screw was tightened. This was why I could rock the end of the tool.

Grinding the tip of the pin to provide some clearance eliminated the rocking and the visible gap was gone, but created another problem. Now when I ran the adjustment screw through its range the bottom of the head would suddenly loosen after a few turns. This problem was solved by filing the edges of the dovetails on the top part of the head (two arrows from the left), and deburring every other machined edge.

Now the cutting tool is held solid and the adjustment screw takes even pressure throughout its range.

Hope you find this helpful.

Eric

The first two holes I bored with mine I did get good results, probably from my ignorance, but I noticed I could rock the tool around where the top and bottom of the head clamp together. Also with the clamp screw tight there was a visible gap between the top and bottom parts of the head. Not knowing any better I figured that's just the way it's designed.

The next hole I tried I couldn't get anything to go right, so I decided to figure out what was going on.

What I found was the hardened steel pin that the end of the adjusting screw bears upon, that Sherline calls the Gear Drive Pin, was making contact with the bottom half of the head when the clamp screw was tightened. This was why I could rock the end of the tool.

Grinding the tip of the pin to provide some clearance eliminated the rocking and the visible gap was gone, but created another problem. Now when I ran the adjustment screw through its range the bottom of the head would suddenly loosen after a few turns. This problem was solved by filing the edges of the dovetails on the top part of the head (two arrows from the left), and deburring every other machined edge.

Now the cutting tool is held solid and the adjustment screw takes even pressure throughout its range.

Hope you find this helpful.

Eric