- Joined

- Apr 20, 2011

- Messages

- 430

As they say "been there and done that" (I hate that saying)

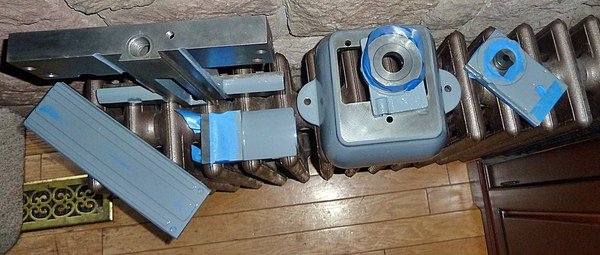

I bought my 13" Sheldon for $650 (sound familiar) and while it didnt have quite the rust yours has, it was a wreck condition wise! It had a very unusual under drive that Mr Knox over on the yahoo site called the "walking stick drive" (you've GOT to get joined up over there, Mr Knox is an encyclopedia on Sheldons) Heres a link to a write up on it on Tonys website

http://www.lathes.co.uk/sheldon/page8.html

Lemme pause here and say that I do have some rust experience - I bought a 13" South Bend and a 10" Emco

that had gone thru hurricane Katrina and sat for some 5 years and they were BAD, the ways were at least as bad as yours and probably worse. I'm still using the SB after 6 yrs now and even with the pitted ways (oil holders) the lathe performs like a dream. Seriously, its pretty doubtful the pits will affect the operation of the lathe - now wear is a different story. I mainly use media (sand) blasting for my clean ups, along with LOTs of elbow grease - 3M pads, wire wheels etc .

As you are finding out, there is a ton of work in reclaiming one of these but you can never figure your time in them, you have to do it out of the love and appreciation of seeing a fine old piece (ole merican arn!) like this come back to life. My hobby is finding these old jewels and doing just that, I had some $1500 money in my Sheldon and I sold it for $2500 after 30mins on Craig list, then got some 4-5 other calls (as the fella was coming to pick it up a guy offered me 3000 if I would let him have it!!) I greatly agonized over whether to sell the SB or the Sheldon, I really liked the Sheldon, but in the end the newer model SB with the enclosed gearbox won out,

I suspect that your Sheldon being ex military will have negligible wear - my SB was off a Coast Guard ship and apparently had very little use. You are right in figuring on needing to replace the dials, I've replaced them on every lathe I've rebuilt. As you said those tiny little dials need to be replaced anyway.

Have Fun!!

I bought my 13" Sheldon for $650 (sound familiar) and while it didnt have quite the rust yours has, it was a wreck condition wise! It had a very unusual under drive that Mr Knox over on the yahoo site called the "walking stick drive" (you've GOT to get joined up over there, Mr Knox is an encyclopedia on Sheldons) Heres a link to a write up on it on Tonys website

http://www.lathes.co.uk/sheldon/page8.html

Lemme pause here and say that I do have some rust experience - I bought a 13" South Bend and a 10" Emco

that had gone thru hurricane Katrina and sat for some 5 years and they were BAD, the ways were at least as bad as yours and probably worse. I'm still using the SB after 6 yrs now and even with the pitted ways (oil holders) the lathe performs like a dream. Seriously, its pretty doubtful the pits will affect the operation of the lathe - now wear is a different story. I mainly use media (sand) blasting for my clean ups, along with LOTs of elbow grease - 3M pads, wire wheels etc .

As you are finding out, there is a ton of work in reclaiming one of these but you can never figure your time in them, you have to do it out of the love and appreciation of seeing a fine old piece (ole merican arn!) like this come back to life. My hobby is finding these old jewels and doing just that, I had some $1500 money in my Sheldon and I sold it for $2500 after 30mins on Craig list, then got some 4-5 other calls (as the fella was coming to pick it up a guy offered me 3000 if I would let him have it!!) I greatly agonized over whether to sell the SB or the Sheldon, I really liked the Sheldon, but in the end the newer model SB with the enclosed gearbox won out,

I suspect that your Sheldon being ex military will have negligible wear - my SB was off a Coast Guard ship and apparently had very little use. You are right in figuring on needing to replace the dials, I've replaced them on every lathe I've rebuilt. As you said those tiny little dials need to be replaced anyway.

Have Fun!!