- Joined

- Dec 12, 2014

- Messages

- 261

Hi all,

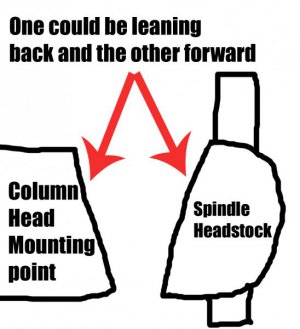

It's been a little while since I've touched some scraping projects. I've been on a roll of machinery upgrades, namely the new to me Wells-Index Super 55. But, that has only lead me back to scraping and checking of machinery. As I've been reading Machine Tool Reconditioning(RTC), I've noted the sequence clearly outlined on where to start checking and where a scraper would begin. If I'm understanding this correctly, the book lays out that a datum point for a vertical mill would be the spindle. Using that as the datum point, one would progress to a sequence of checks starting on the column, then to the knee, etc., etc. There is a part of me seriously contemplating such a project, but I may hold off for now. However, I still want to work through the exercise of checking the state for all ways and sliding members. As you will see the machine is going through a complete tear down. The spindle has been sent to Wells-Index for a regrind to R8. I'm asking the following:

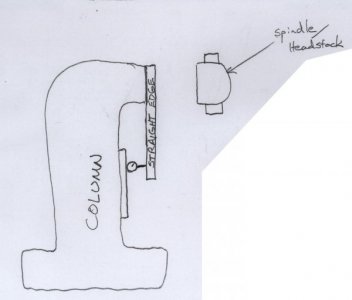

Could the mounting plate for the vertical head be the datum point? This machine does NOT have the ability to nod the head. RTC recommends laying the column down to scrape the flat ways and then rotate the column to scrape the dovetails. My cast iron plate is large enough to cover the entire surface of the column way and it has two rods that can be used to easily maneuver the plate. Should I go for it or is there another method to check the vertical head mount relationship to the column way? I was considering a straight edge held flat against the head mount and extending down. This would allow me slide an indicator across the straight edge.

Second question:

Does one HAVE to start at the datum point and then proceed to the knee, saddle, then table? I ask because a quick check shows that the table retains original scrape marks at the ends and has .002" of wear in the middle. According to the text, if original factory scrape marks are present I should be able to use the original scrape marks as my starting point and scrape to the lowest point. Thus scraping straight down.

Alright, I'm tired. Hope all of this makes sense.

It's been a little while since I've touched some scraping projects. I've been on a roll of machinery upgrades, namely the new to me Wells-Index Super 55. But, that has only lead me back to scraping and checking of machinery. As I've been reading Machine Tool Reconditioning(RTC), I've noted the sequence clearly outlined on where to start checking and where a scraper would begin. If I'm understanding this correctly, the book lays out that a datum point for a vertical mill would be the spindle. Using that as the datum point, one would progress to a sequence of checks starting on the column, then to the knee, etc., etc. There is a part of me seriously contemplating such a project, but I may hold off for now. However, I still want to work through the exercise of checking the state for all ways and sliding members. As you will see the machine is going through a complete tear down. The spindle has been sent to Wells-Index for a regrind to R8. I'm asking the following:

Could the mounting plate for the vertical head be the datum point? This machine does NOT have the ability to nod the head. RTC recommends laying the column down to scrape the flat ways and then rotate the column to scrape the dovetails. My cast iron plate is large enough to cover the entire surface of the column way and it has two rods that can be used to easily maneuver the plate. Should I go for it or is there another method to check the vertical head mount relationship to the column way? I was considering a straight edge held flat against the head mount and extending down. This would allow me slide an indicator across the straight edge.

Second question:

Does one HAVE to start at the datum point and then proceed to the knee, saddle, then table? I ask because a quick check shows that the table retains original scrape marks at the ends and has .002" of wear in the middle. According to the text, if original factory scrape marks are present I should be able to use the original scrape marks as my starting point and scrape to the lowest point. Thus scraping straight down.

Alright, I'm tired. Hope all of this makes sense.

Last edited: