- Joined

- May 7, 2014

- Messages

- 776

Update: Much Much better performance after quite a learning experience. Here is the follow-up to help future Newbs possibly.

Machine: Shopmaster Patriot. Not the new Mill Turn.

There were several helps on this noted below.

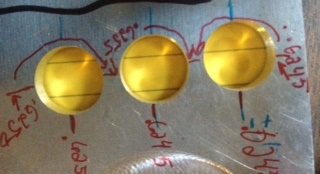

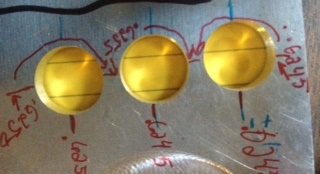

All circles are right in there now! Very close (.001 / .002 ) from circle to circle. And .001 to .002 in 2 measurements 90' apart on circle. Ran groups of three circles 3 times. What seems really cool now is that Mach3 and the glass DRO's are displaying tens to a thou difference. Fluke or finally dialed in- Time will tell. But cool to see.

Learned a Lot! Experiment, learn, repeat. Man this stuff is not for the impatient that is for sure.

CGout.

Machine: Shopmaster Patriot. Not the new Mill Turn.

There were several helps on this noted below.

- Setup Backlash adjustments. Gage based Measurements, Motor tuning, and Mach3settings based on Hoss Vid.

- Mach3- Turn off CV on angles >90 degrees (Mach3, General config settings checkbox) Read to try in a few places.

- Fixing the Quill movement via a socket-screw into a machined quill slot. (biggest gains on this 1 fix for me).

- Setting the tapered gib adjustments and experimenting with too loose, too tight- until best results.

All circles are right in there now! Very close (.001 / .002 ) from circle to circle. And .001 to .002 in 2 measurements 90' apart on circle. Ran groups of three circles 3 times. What seems really cool now is that Mach3 and the glass DRO's are displaying tens to a thou difference. Fluke or finally dialed in- Time will tell. But cool to see.

Learned a Lot! Experiment, learn, repeat. Man this stuff is not for the impatient that is for sure.

CGout.