Here is a list of all the parts/work that was done...

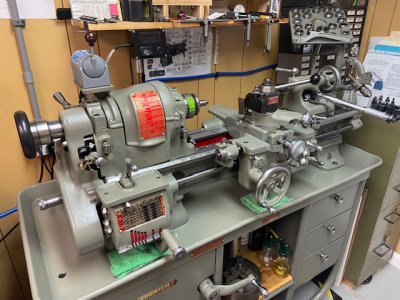

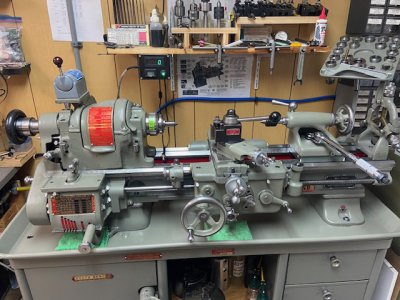

SOUTH BEND 10LX TOOLROOM PRECISION LATHE

Model No. CL8187ZN 3-1/2 Ft Bed SN: 168288

Ordered 27 Aug 1945 / Delivered: 10 Dec 1945

Rebuilt & Restored March 2023 – January 2024

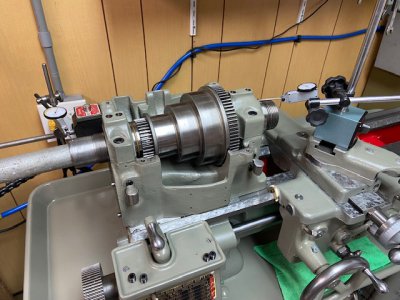

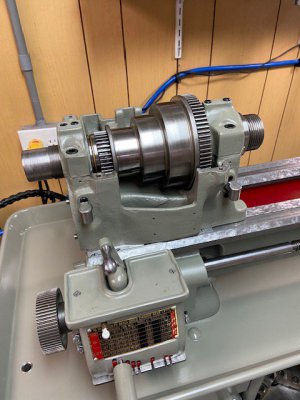

HEADSTOCK

New Oiling Data Plate w/ new drive screws

New Bearing Adjustment Data Plate w/ new drive screws

New S/S Cover hinge screws and jamb nuts

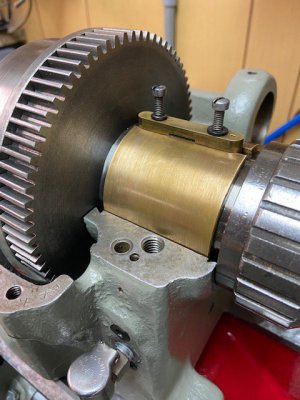

NOS Bronze Spindle Bearings and Expanders

New Felts

New laminated brass bearing cap shims

Original bolts & screws refinished in black oxide

New Capillary oiler tubes mfr’d & refitted

New capillary oilers

New Back Gear dog point set screw mfr’d

New spindle take up nut washer replaced w/ bronze oilite washer/bearing & bearing surface refinished

Spindle gear replaced with NOS item

Twin gears (Reversing gears) replaced with new gears with sealed roller bearings (American Machine & Gearworks)

All taper pins replaced with S/S pins & holes clean-up reamed

New oiling felts installed in reversing gear assembly

New ½ height S/S nut installed on reversing gear stud

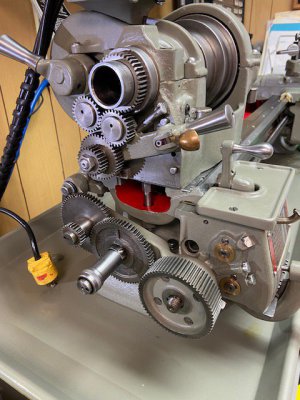

GEAR TRAIN ASSY

Primary Guard Cover screws converted to studs with acorn nuts

Data plates restored

Primary drive gear replaced with NOS item

Primary bracket (Banjo bracket) mounting stud replaced with S/S bolt & hardened washers

APRON

NOS Worm Gear installed

NOS Worm Gear Collar installed

NOS Worm Gear Bushing installed

NOS Worm Gear pins installed

NOS Worm Gear / Lead Screw Key installed

Rebuilt Star Clutch Assy

NOS Star clutch L/H screw installed

Apron oiler tube installed (previously missing)

Gits oiler installed for Apron Hand wheel shaft (modification)

New sump cover gasket installed & sealed

New oiling felt-wicks installed throughout

All taper pins replaced with S/S pins & holes clean-up reamed

SADDLE ASSY

NOS Complete Direct Reading (Lg Dial) Assy installed

New ball crank handle nut installed

Threading Stop Assy Installed with hex head shoulder bolt.

Gib replaced and shimmed

New wipers installed

Wiper retainers refinished

Wiper retainer screw replaced with new S/S screws

Wipers & brass holders modified for lower height / new screws custom fit

NOS bronze Cross Feed screw nut installed

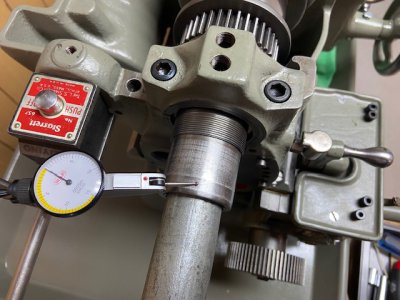

Cross Feed ways planed and scraped perpendicular to spindle Center Line.

Saddle ways planed & scraped to fit bed.

Saddle gib shimmed to provide .002 clearance

New Gib adjustment screw lock screw installed

Follow rest mounting holes plugged with set screws

Taper attachment mounting holes plugged with set screws

COMPOUND REST ASSY

Complete Direct Reading (Lg Dial) Assy installed

Compound screw straitened to > .0015 TIR

New Compound Rest nut installed (brass)

New ball crank handle nut installed

Gib replaced

New Gib adjustment screw lock screw installed

SINGLE TUMBLER GEAR BOX

New Gits oilers installed (8)

Gits oiler tube installed as mod for tumber/idler gear lube.

Restored brass data plate installed

NOS Pinion gear installed

Custom made Idler gear mfr’s & installed

New Timken roller bear installed for idler gear/shft

New custom made bronze bearings mfr’d for Clutch Lever gear shaft & Cone Gear shaft

Bearing diameters on shafts turned to .500”

All taper pins replaced with S/S pins & holes clean-up reamed

Oil passage set screws for clutch lever shaft replaced with new.

New oiling felts installed throughout

TAIL STOCK ASSY

Quill cleaned & polished

New felt washer installed on quill screw

New rubber washer installed on quill screw

Quill wheel nut replaced with acorn nut

NOS Tail Stock clamp installed

New felt wipers installed

Tail stock based planed and scraped to fit bed

Shims installed between base and housing to account for planning and scraping (.008”)

BED ASSY

Bed ways and flats planed and scraped (-.036”)

Rack gear shimmed down to account for planning (.058” brass stock)

Gearbox mounting shimmed down to account for planning (.058” brass stock)

Lead screw support bearing shimmed down to account for planning (.058” brass stock)

New gaskets mfr’d for Head stock & tail stock bed mounts (Felpro Karopak)

New S/S screws for lead screw / gearbox cover

New S/S screws for rack gear (longer)

Rebuild & Planing/Scraping Data Plate installed on back side of bed.

MISCELLANEOUS

NOS motor pulley installed (PT213K2)

New 5L44 V belt installed

Cabinet drawer slides rebuilt.

Cabinet drawer locks/latches rebuilt

Original cabinet badging & data plates installed

Anti-vibration pads installed for motor mount (8)

Anti-vibration leveling legs installed on cabinet legs (4)

Wood center shelf install w/ under cabinet lighting

South Bend Forward / Reverse switch mount installed on quill guard

Square D switch rebuilt / restored

All handles and knobs polished

Installed ball oiler on flat belt tension lever shaft housing

Rubber / Nylon flat belt (glued) installed (59-1/4”)

OVERALL

All parts / entire machine detail stripped, cleaned & gauged – all parts repaired or replaced as needed and new paint applied – Sherwin William SB Gray (Custom mix 11-1321). Chip tray further coated with VHT Engine Clear Coat (Gloss)

All unpainted / non lubricated surfaces treated with Boeshield T-9

All way planning & scraping performed by:

Rees Acheson

Alstead, NH

ACCESSORIES

Hand Wheel Collet Closer w/ 42 Collets, Wrench, & (2) spindle thread protector nuts.

Collet Storage Rack (stripped, cleaned, painted & restored)

Micrometer Carriage Stop (stripped, cleaned, painted & restored)

Threading Dial (stripped, cleaned, painted & restored)

Threading C.F. Stop (stripped, cleaned, painted & restored)

Telescoping Steady Rest

Aloris AXA Tool Post installed

UPGRADES

Digital Tachometer installed

LUBRICANTS

New lubricants obtained:

Mobil DTE Heavy Medium 26 (General Lube),

Mobil DTE Light 22 (Gearbox),

Mobil Velocite 10 (Spindle)

Super Lube ISO 150 EP (Ways),

Super Lube Synthetic Grease (Back gear)

Roy Dean DE112 Grease (Back gear / cone pulley)