- Joined

- Mar 29, 2017

- Messages

- 746

So- my Millrite is up and running. See my earlier thread in this forum. (Big "high five" to the folks here and at Automation Direct". Bought the GS 2, easy programming, no sweat. GOOD manual)

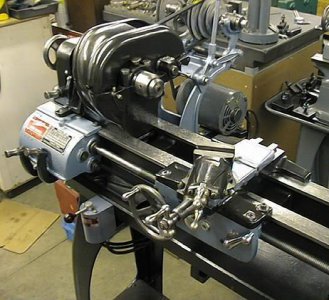

Now that is done, I am on to repairing my old, WORN OUT,12x36 craftsman/atlas lathe. The bed is worn both on carriage areas, and tailstock areas, of the ways. I am aware of the various options, concerning repair. Am I insane, or just overly optomistic, about my chances to make it better, not RIGHT, but BETTER, by attempting a repair of the bed on the mill? Just take it down, or epoxy back to original, or grind it, or SCRAP it? Max wear about .004 on carriage area, next to the headstock. I aint never gonna get a contract from NASA, I am just intrigued by my newfound options, and the challenge. I look forward to hearing this varied group weigh in. Pull NO punches, please.

Now that is done, I am on to repairing my old, WORN OUT,12x36 craftsman/atlas lathe. The bed is worn both on carriage areas, and tailstock areas, of the ways. I am aware of the various options, concerning repair. Am I insane, or just overly optomistic, about my chances to make it better, not RIGHT, but BETTER, by attempting a repair of the bed on the mill? Just take it down, or epoxy back to original, or grind it, or SCRAP it? Max wear about .004 on carriage area, next to the headstock. I aint never gonna get a contract from NASA, I am just intrigued by my newfound options, and the challenge. I look forward to hearing this varied group weigh in. Pull NO punches, please.