-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rt Fixture Plate

- Thread starter dlane

- Start date

- Joined

- Dec 27, 2014

- Messages

- 658

Not sure I follow.

You protect the table on the RT the same way you protect the table on your mill with clamps, fixture plates, vises, etc.

Pallets and fixtures are generally considered sacrificial. You just mill right into them when you need to and clean them up as part of maintenance.

I have never used a fixture plate on the RT, I usually just clamp the work to the table, or put it in a 4jaw chuck. The few times I have had to mill to the bottom of a part, I have just put a spacer under the work so I don't hit the RT.

I'd like to have one, but it has never been worth the time or money to make one for the few times it would simplify things up this point. I am sure I will acquire one eventually though.

You protect the table on the RT the same way you protect the table on your mill with clamps, fixture plates, vises, etc.

Pallets and fixtures are generally considered sacrificial. You just mill right into them when you need to and clean them up as part of maintenance.

I have never used a fixture plate on the RT, I usually just clamp the work to the table, or put it in a 4jaw chuck. The few times I have had to mill to the bottom of a part, I have just put a spacer under the work so I don't hit the RT.

I'd like to have one, but it has never been worth the time or money to make one for the few times it would simplify things up this point. I am sure I will acquire one eventually though.

- Joined

- Dec 27, 2014

- Messages

- 658

... what is preferred spacer material ,aluminum, steel , wood , plastic

...

Whatever is the right size and too slow to get away

1-2-3 blocks are what I probably use most of the time, I have 4 pairs of cheap Chinese ones for this purpose. I also use parallels, machinists jacks, marble countertop scraps, chunks of metal from the scrap bin.

For one off work, cost is the biggest consideration. MDF, plywood, and paper are all cheap and often solid enough to use as machining spacers depending on what you are cutting and how heavy a cut. If you have to machine into the spacer, soft material is better.

- Joined

- Sep 27, 2014

- Messages

- 3,123

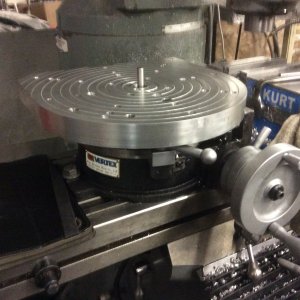

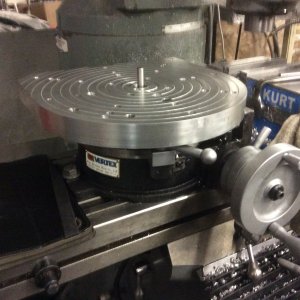

Hi all , so it ended up being 12"ish x 1-1/4" thick ,kinda square / kinda round, the 3/8 dowell in the center is a slip fit into a mt3 Chuck arbor that I turned the JT 6 end down to .750 that slips into the reemed .750 center hole in plate. It has several 3/8-16 and 3/8 reamed holes for mounting clamps and dowell pins . I think it will work for my needs

Scribe lines are .500 apart , solid pin at 0 deg 3" is a snug fit in t slot ,red locktighted in plate.

That aluminum was slow cutting on my Doall vert band saw with a 10-14 very pitch blade .

This was a learning experience

Thanks

Scribe lines are .500 apart , solid pin at 0 deg 3" is a snug fit in t slot ,red locktighted in plate.

That aluminum was slow cutting on my Doall vert band saw with a 10-14 very pitch blade .

This was a learning experience

Thanks

- Joined

- Dec 27, 2014

- Messages

- 658

BAH!

Now I'm going to have to make one

Fine work!

Now I'm going to have to make one

Fine work!

- Joined

- Sep 27, 2014

- Messages

- 3,123

Had some spare chucks lying around , I mounted a craftsman 8" 4jaw to the RT fixture plate.

I made a plug that fits the Chuck back hole snugly and a reemed 3/8 center hole to center the Chuck on plate , then drilled , taped 4 3/8-16 holes in plate to bolt the Chuck to it

May have to figure a way to mount a spare 6" 3jaw to it also , this plate is getting holy.

Going to start a thread on chucks in QA to see witch would be best

Going to start a thread on chucks in QA to see witch would be best

Thanks for the help

I made a plug that fits the Chuck back hole snugly and a reemed 3/8 center hole to center the Chuck on plate , then drilled , taped 4 3/8-16 holes in plate to bolt the Chuck to it

May have to figure a way to mount a spare 6" 3jaw to it also , this plate is getting holy.

Going to start a thread on chucks in QA to see witch would be best

Going to start a thread on chucks in QA to see witch would be bestThanks for the help