- Joined

- Jun 20, 2022

- Messages

- 235

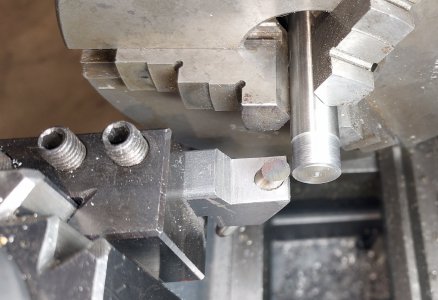

Saw a few tangential tool holder builds, and some made round tool holders of the same ilk. Thought this is an easy-ish project. Lathe, portaband, grinder and drill press are the only tools needed. All milling operations can easily be done in the tool holder on the lathe that the tool goes in with a cutter in a collet chuck.

This is unfinished/test piece, but test cuts leave VERY nice surface finish. Test cuts on 12l14 and drill rod both look great. Perhaps because it is so easy to get the tool razor sharp with one lick on the grinder.

So for fellow beginners looking for a project to develop skills this is a nice project done in a couple evenings with minimal tools.

Super cheap. Uses only a chunk of 1/2" scrap steel for the body, and a broken 1/4" end mill or drill bit.

Unfortunately I badly screwed up the set screw drilling because of the slope the bit wandered. It still works fine but I may re-make it. It still needs relief cuts along the front and sides so the tool can face off work without rubbing.

This is unfinished/test piece, but test cuts leave VERY nice surface finish. Test cuts on 12l14 and drill rod both look great. Perhaps because it is so easy to get the tool razor sharp with one lick on the grinder.

So for fellow beginners looking for a project to develop skills this is a nice project done in a couple evenings with minimal tools.

Super cheap. Uses only a chunk of 1/2" scrap steel for the body, and a broken 1/4" end mill or drill bit.

Unfortunately I badly screwed up the set screw drilling because of the slope the bit wandered. It still works fine but I may re-make it. It still needs relief cuts along the front and sides so the tool can face off work without rubbing.