- Joined

- Oct 31, 2016

- Messages

- 2,720

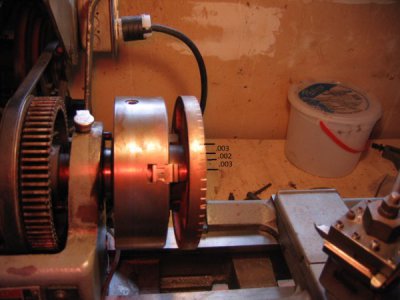

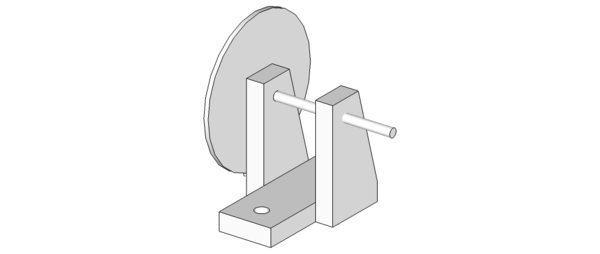

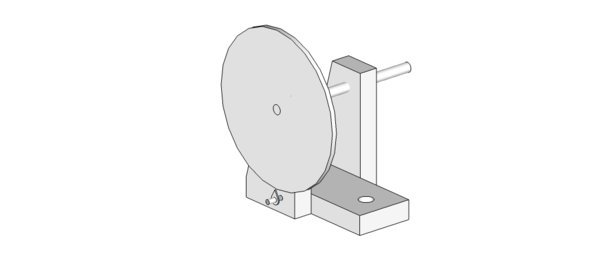

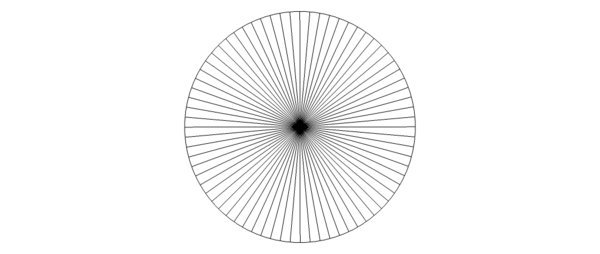

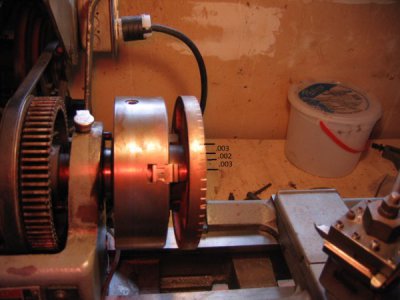

I need a rotary table. My lathe came with a fixture that could be secured to a milling table that was threaded to accept a lathe chuck. I thought that this could be the basis for a rotary table. Any of my lathe chucks or backing plates can be mounted on this fixture. A picture of it mounted in my Craftsman 12x36 lathe is attached. I don't want to take it out of the chuck because I will loose my reference. So I apologize for not having a better picture of it. The lathe has an indexing feature with 60 holes equally spaced around one of the gears. So I chucked the fixture in my lathe and proceeded to scribe marks using the indexing feature around the outside diameter of the fixture. The marks were just over .300 apart. When I got all the way around the last mark was just over .200 from the first mark. A picture is attached. I thought with the indexing feature on my lathe the marks should have been properly spaced around the outside diameter of the fixture. I checked the run out on the fixture in the chuck and the run out is .006. I don't know if that has any bearing on this.

The only two things that I can think of that might have caused this is 1) I didn't have the fixture tight enough in the chuck and each time I scribed a mark the fixture moved an infinitesimal amount or 2) the chuck was not tight enough on the lathe spindle and moved every time I scribed a mark.

Any ideas on what caused this?

Chuck

The only two things that I can think of that might have caused this is 1) I didn't have the fixture tight enough in the chuck and each time I scribed a mark the fixture moved an infinitesimal amount or 2) the chuck was not tight enough on the lathe spindle and moved every time I scribed a mark.

Any ideas on what caused this?

Chuck