- Joined

- Sep 24, 2012

- Messages

- 502

This is a shot in the dark, but I'm looking for name/contact info for someone willing to open up the headstock of a Rivett 1R watchmaker's lathe.

Before you ask, NO, I can't seem to do it myself.

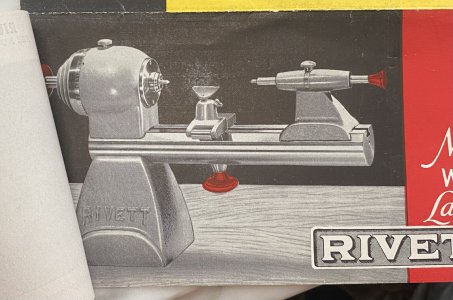

Those were the lathes with the ball-bearing headstocks instead of Rivett's traditional cone spindles. The lathe I'm hoping to have worked on has some severe issues - the headstock will turn given enough effort, but it's extremely bumpy-feeling when turned. I've been told the worst thing to do is try to turn it - which is what I've done several times before I was told about the damaging effects of turning by force. And....that's not the only issue... the internal locking pin (inside the spindle) that secures the collet appears to be snapped off & missing.

I have read about a guy named James P. Riser who seems to be exactly the kind of guy I'd like to see tackle the job, but he seems unreachable.

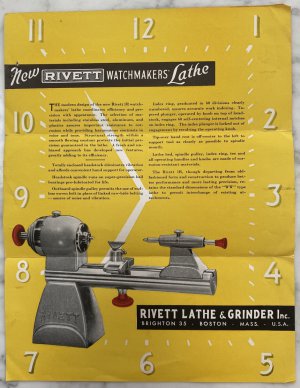

I'm attaching pics of an old Rivett brochure to show the lathe in question.

Suggestions welcome.

Before you ask, NO, I can't seem to do it myself.

Those were the lathes with the ball-bearing headstocks instead of Rivett's traditional cone spindles. The lathe I'm hoping to have worked on has some severe issues - the headstock will turn given enough effort, but it's extremely bumpy-feeling when turned. I've been told the worst thing to do is try to turn it - which is what I've done several times before I was told about the damaging effects of turning by force. And....that's not the only issue... the internal locking pin (inside the spindle) that secures the collet appears to be snapped off & missing.

I have read about a guy named James P. Riser who seems to be exactly the kind of guy I'd like to see tackle the job, but he seems unreachable.

I'm attaching pics of an old Rivett brochure to show the lathe in question.

Suggestions welcome.