-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Requesting advice on motor/pulley setup for Sears 109 21270

- Thread starter Deepcover

- Start date

- Joined

- Apr 5, 2013

- Messages

- 391

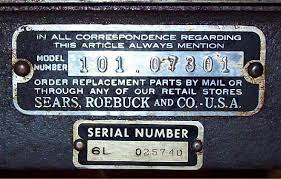

Hi aoresteen , the model I have is a Atlas/Craftsman 101.07301 , my bad I should have said that . The 101.07031 has bronze sleeve type bearings , all the other versions of the Atlas 6" lathe have roller or ball bearings .Mark,

I am not aware of a 109.07031 model. Can you post a photo of the model tag?

Thanks!

This is not my tag but just like it except for the serial # , mine doesn't have one

Here is a good read about the Dunlap 109 . Dunlap and Atlas are two different Co.s , although Sears sold both as the Craftsman

AA109, Craftsman 80, Dunlap, Simpson & Courlan Lathes

History and development of the Craftsman, Dunlap, Companion, Metalcraft, Metalmaster, AA109, 109, Simpson and Courlan and manufactured by the American

www.lathes.co.uk

Last edited:

- Joined

- May 21, 2022

- Messages

- 46

The biggest problem with the 109 is not the spindle, it is the speed. It is just not slow enough. If you have just a plain pulley in the headstock you need to get the "planetary" backgear set with a 3 step pulley. Like this one:

This will reduce the spindle speed to 1/5 of the speed when engaged. It is a must on the 109. My109.0703 109.0702 didn't have one (although it came with one from the factory when it was made in 1941) when I got it. I bought the best one I could find off of eBay (I am in the process of replacing the bearings in the backgear - they have a reputation for being noisy).

You can see one being pulled apart at 9:42 in this video:

With a regular pulley & motor, the 109 can have speeds of 580 to 2040 RPM which is way to fast to cut gears or work with steel. Even with the planetary backgear unit, with a 1750 RPM motor your lowest speed will be around 116 rpm. Better, but it needs to be down in the 55 RPM range to be truly useful.

To control the speed of a 109, options are:

1) DC motors with VFD, or

2) Countershaft setup, or

3) a slower AC motor of say 900 RPM and forgo high speeds altogether.

I've decided on building a countershaft, option 2.

I found an esoteric mention of a Craftsman countershaft for the 109 on the British website www.lathe.co.UK. It reads:

"...Obviously aware of the limitations imposed by this arrangement, the Company (Craftsman) offered later versions with the option of a double-step pulley on the motor and a proper countershaft assembly, thus doubling the number of speeds and giving, according to the handbook, a range from 55 to 465 rpm in backgear and from 380 to 3050 in direct drive - a very much more satisfactory arrangement."

This is the only reference that I have been able to find about the existence of a factory countershaft setup for the 109. I'd just like to see a photo of it so I could start making one. Perhaps they are wrong but I hope not.

Bent shafts on the 109 are due to worn bearings, too fast speeds and improper tool alignment (operator error).

For $120 You can get a new replacement spindle made from 4140 steel that is far stronger that the original ones made 70 years ago. I bought one and opted for the original 1/2" x 20 TPI thread but they are available with a 3/4" x 16 TPI. Look on eBay.

My need for a lathe is to make 7/8" x 2" round parts out of aluminum which the 109 can do very well.

This will reduce the spindle speed to 1/5 of the speed when engaged. It is a must on the 109. My

You can see one being pulled apart at 9:42 in this video:

With a regular pulley & motor, the 109 can have speeds of 580 to 2040 RPM which is way to fast to cut gears or work with steel. Even with the planetary backgear unit, with a 1750 RPM motor your lowest speed will be around 116 rpm. Better, but it needs to be down in the 55 RPM range to be truly useful.

To control the speed of a 109, options are:

1) DC motors with VFD, or

2) Countershaft setup, or

3) a slower AC motor of say 900 RPM and forgo high speeds altogether.

I've decided on building a countershaft, option 2.

I found an esoteric mention of a Craftsman countershaft for the 109 on the British website www.lathe.co.UK. It reads:

"...Obviously aware of the limitations imposed by this arrangement, the Company (Craftsman) offered later versions with the option of a double-step pulley on the motor and a proper countershaft assembly, thus doubling the number of speeds and giving, according to the handbook, a range from 55 to 465 rpm in backgear and from 380 to 3050 in direct drive - a very much more satisfactory arrangement."

AA109, Craftsman 80, Dunlap, Simpson & Courlan Lathes

History and development of the Craftsman, Dunlap, Companion, Metalcraft, Metalmaster, AA109, 109, Simpson and Courlan and manufactured by the American

www.lathes.co.uk

This is the only reference that I have been able to find about the existence of a factory countershaft setup for the 109. I'd just like to see a photo of it so I could start making one. Perhaps they are wrong but I hope not.

Bent shafts on the 109 are due to worn bearings, too fast speeds and improper tool alignment (operator error).

For $120 You can get a new replacement spindle made from 4140 steel that is far stronger that the original ones made 70 years ago. I bought one and opted for the original 1/2" x 20 TPI thread but they are available with a 3/4" x 16 TPI. Look on eBay.

My need for a lathe is to make 7/8" x 2" round parts out of aluminum which the 109 can do very well.

Last edited:

- Joined

- Dec 25, 2011

- Messages

- 10,552

The model number of the Atlas 6" is either 612 or 618. The four 6" models made by Atlas and sold by Sears are 101.07300, 101.07301. 101.21400 and 101.21200. In each case, "101" is the Sears Contractor Code for Atlas.

The first model listed is very rare and was only made for one year. The last model number listed was the ball-bearing Mk 2. The 101.21400 is the same except for badge as the 618.

The first model listed is very rare and was only made for one year. The last model number listed was the ball-bearing Mk 2. The 101.21400 is the same except for badge as the 618.

- Joined

- Dec 25, 2011

- Messages

- 10,552

And the 101.07301 used a lot of 618 parts but the headstock was different as it used sintered bronze spindle bearings and a ball thrust bearing. But in any case, the lathes with Sears model numbers beginning with 109 were built for Sears by AA (sometimes seen as Double-A).

- Joined

- Apr 5, 2013

- Messages

- 391

- Joined

- May 21, 2022

- Messages

- 46

aoresteen , I think the countershaft assy . from the older Atlas 6" machines would be a good match for what you need .

Here is the older one .

View attachment 408301

Yes, I've been looking for that one with no luck. I just bought one for an Atlas 10/12" that I will have to re-work a bit for my 109. Is yours for sale?

- Joined

- Apr 5, 2013

- Messages

- 391

Sorry Tony , not for sale . I'm in the market for one myself as mine is missing the eccentric lever and has a repair . There is a guy on the bay that has a lot of stuff , a guy from here dealt with him , I don't know how it turned out but the guy said he was slow to respond to questions .

Mark .

Mark .

Atlas Craftsman 6 inch Lathe PICK YOUR PARTS 618 also 3 complete lathes | eBay

I am not cleaning anything any more. All this stuff has been sitting on my garage since my dad got sick I am guessing 11 years or more now. ding or mark on everything. If I can not then I must take pictures of everything.

www.ebay.com

- Joined

- May 21, 2022

- Messages

- 46

Sorry Tony , not for sale . I'm in the market for one myself as mine is missing the eccentric lever and has a repair . Their is a guy on the bay that has a lot of stuff , a guy from here dealt with him , I don't know how it turned out but the guy said he was slow to respond to questions .

Mark .

Atlas Craftsman 6 inch Lathe PICK YOUR PARTS 618 also 3 complete lathes | eBay

I am not cleaning anything any more. All this stuff has been sitting on my garage since my dad got sick I am guessing 11 years or more now. ding or mark on everything. If I can not then I must take pictures of everything.www.ebay.com

Thanks! I sent him a PM on eBay. Let's see if and when he responds.