- Joined

- Jul 6, 2021

- Messages

- 12

First of all, I'm unbelievably grateful to all of you for jumping on this problem with me. Thank you.

Here's where I'm at tonight.

Passes, Feeds, and Materials

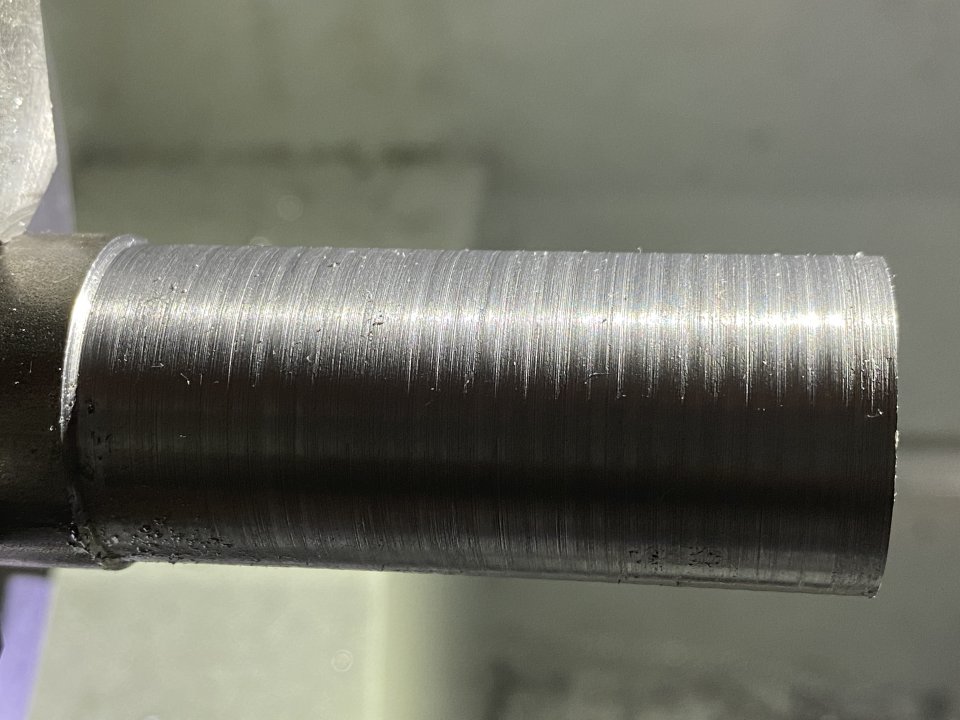

Disclaimer: Many of these passes have crap finish for other reasons. I'm not talking about the overall finish here, that's a totally different topic; I'm specifically investigating the ever present, regular, ripples.

Boy am I blowing through bar stock on test bars. Gotta order more metal. Sticking with free machining steel and 6061 aluminum for now. If I ever get this resolved, I'll have fun with the brass (so pretty but sooo $$$).

Every pass used the same HSS tool. I've replicated this using some other off the shelf tooling with the same results.

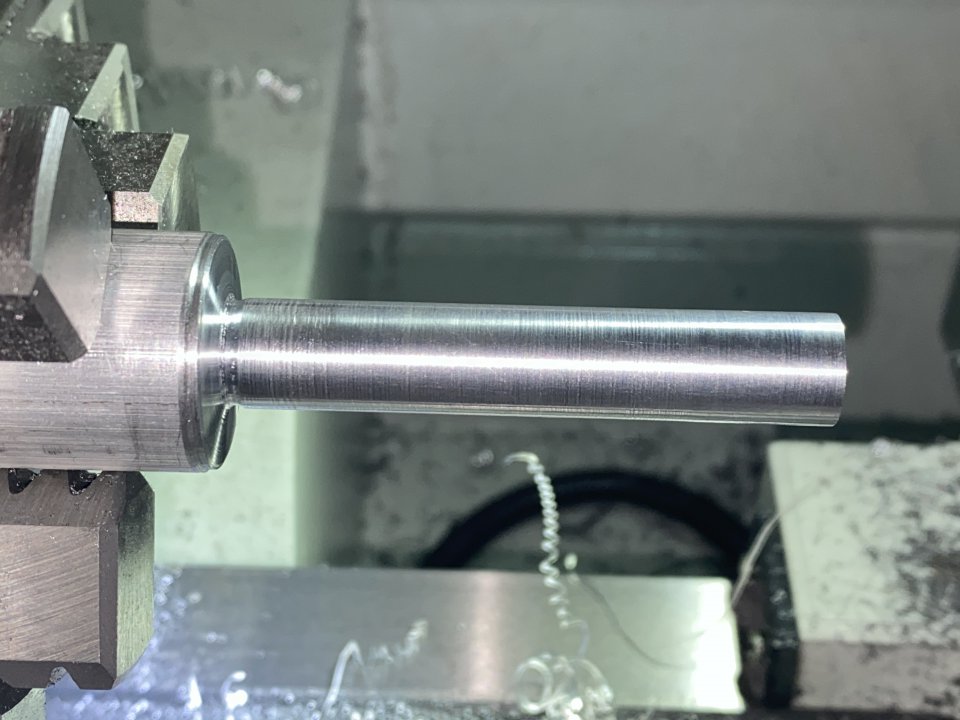

500ish RPM, Manual Feed, 6061, .020 DOC -- Work piece was about .500

I'm not well practiced in manual feeding but it's clear that the pattern didn't show up. I did feel as the pinion transitioned from one gear to the next. This tripped up my smooth turning from time to time. Generally, OK.

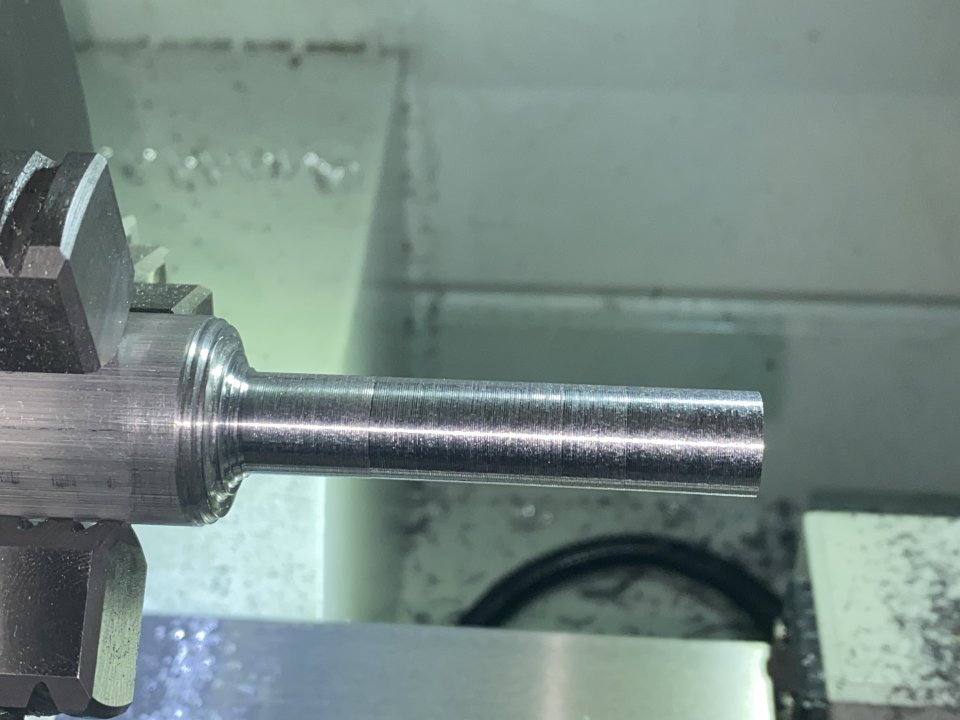

500 RPM, .010/rev, 6061, .020 DOC

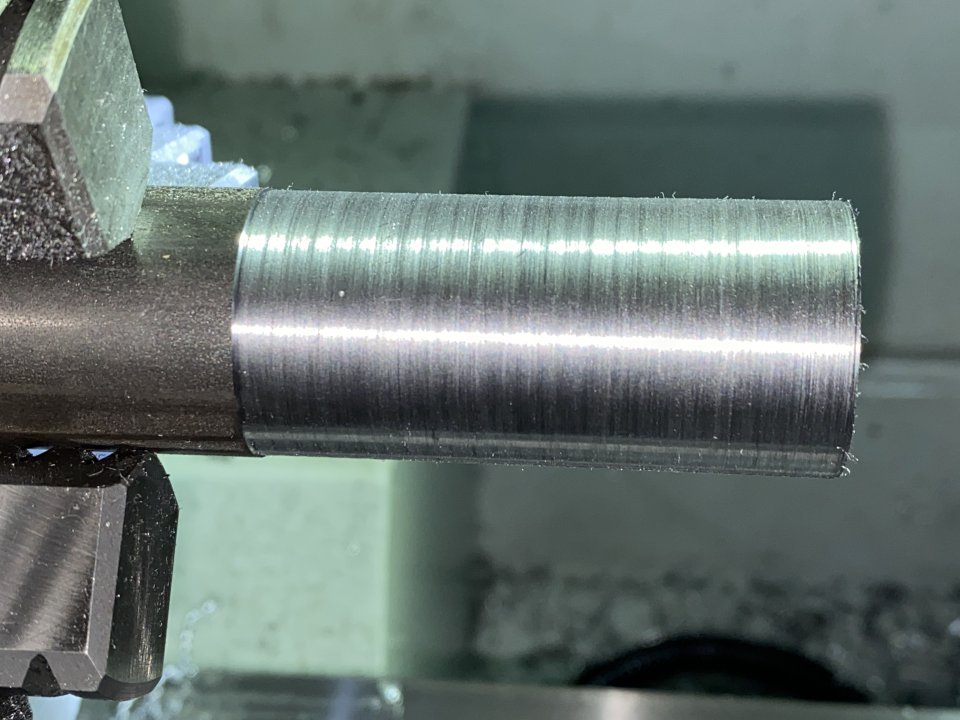

300ish RPM, .0025/rev, 12L14, .020 DOC

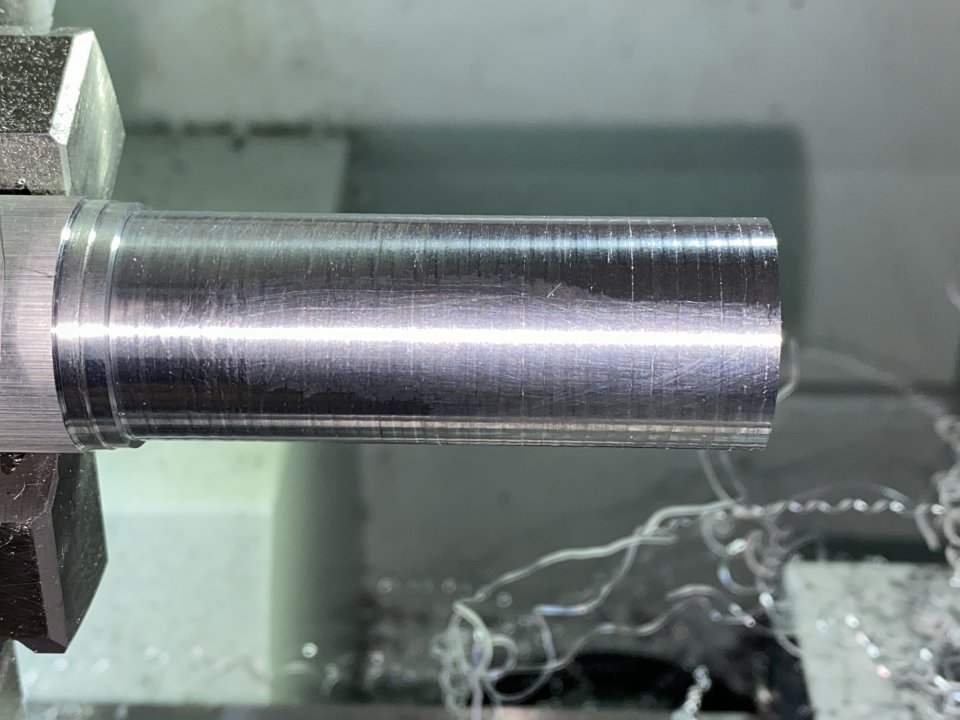

Here are two more passes on the 12L14 but I forgot to write down which was which on the feeds. Both were faster than the slowest which is .0025. As I see it, both of these also clearly show the pattern.

Applying pressure to the hand wheel either helping or opposing the direction of motion doesn't seem to make a difference.

EDIT: The pattern is apparent when power feeding away from the chuck as well.

EDIT: Tail support also makes no difference.

PM also suggested swapping out some change gears to see if there is some eccentricity in them somewhere. I'll try that when I get back next week.

One more test I should try out is a manual spring pass after a power feed pass. This just occurred to me as I was writing so I'll add that to the test list for the next session.

Here's a video running at .0025 in steel. The wine you hear is another annoying issue I'm experiencing with the VFD. That I've solved with ear plugs.

I'll try just about anything at this point. I'm really impressed with this lathe all around but this power feed issue is really making life tricky. I discovered it during initial adjustment when I was working on bed leveling and tailstock alignment. Both are operations during which I was hoping to leverage power feed for consistent cuts.

That's all I have for now.

Regards,

Eilif

Here's where I'm at tonight.

Passes, Feeds, and Materials

Disclaimer: Many of these passes have crap finish for other reasons. I'm not talking about the overall finish here, that's a totally different topic; I'm specifically investigating the ever present, regular, ripples.

Boy am I blowing through bar stock on test bars. Gotta order more metal. Sticking with free machining steel and 6061 aluminum for now. If I ever get this resolved, I'll have fun with the brass (so pretty but sooo $$$).

Every pass used the same HSS tool. I've replicated this using some other off the shelf tooling with the same results.

500ish RPM, Manual Feed, 6061, .020 DOC -- Work piece was about .500

I'm not well practiced in manual feeding but it's clear that the pattern didn't show up. I did feel as the pinion transitioned from one gear to the next. This tripped up my smooth turning from time to time. Generally, OK.

500 RPM, .010/rev, 6061, .020 DOC

300ish RPM, .0025/rev, 12L14, .020 DOC

Here are two more passes on the 12L14 but I forgot to write down which was which on the feeds. Both were faster than the slowest which is .0025. As I see it, both of these also clearly show the pattern.

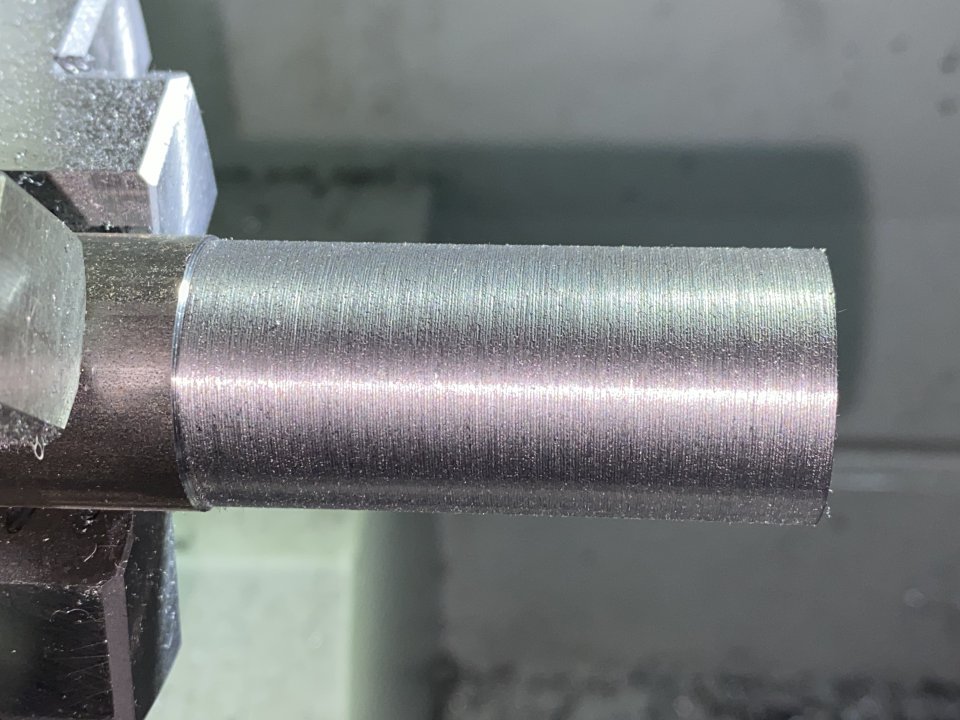

Measuring the Ripples

I took this super lovely pass in 6061. It is glassy smooth to the touch apart from the ripples. I put a tenths DTI on the carriage and ran it over the surface. I measure between 5 and 9 tenths between the low and high spots consistently. I can repeat this measurement on the surface plate if we want to remove the carriage as a source of measurement error.Other observations and Feedback from Precision Mathews

At their suggestion, and in line with the post from "the other forum" I did some inspection of the rack and pinion while under power. I was unable to see anything visually wrong. I snuck an indicator in and was able to measure about 1.5 thou of runout/wobble on the pinion shaft about .25 from the gear. Hard to know if this is having an impact.Applying pressure to the hand wheel either helping or opposing the direction of motion doesn't seem to make a difference.

EDIT: The pattern is apparent when power feeding away from the chuck as well.

EDIT: Tail support also makes no difference.

PM also suggested swapping out some change gears to see if there is some eccentricity in them somewhere. I'll try that when I get back next week.

One more test I should try out is a manual spring pass after a power feed pass. This just occurred to me as I was writing so I'll add that to the test list for the next session.

Here's a video running at .0025 in steel. The wine you hear is another annoying issue I'm experiencing with the VFD. That I've solved with ear plugs.

I'll try just about anything at this point. I'm really impressed with this lathe all around but this power feed issue is really making life tricky. I discovered it during initial adjustment when I was working on bed leveling and tailstock alignment. Both are operations during which I was hoping to leverage power feed for consistent cuts.

That's all I have for now.

Regards,

Eilif

Last edited: