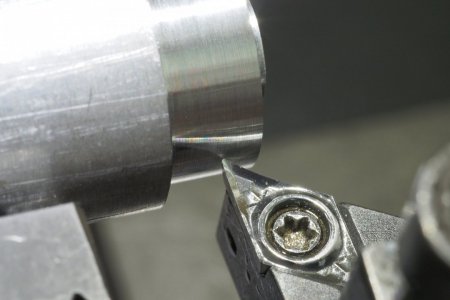

Okay, I think there is some confusion regarding CCGT inserts. Lots of hobby guys think any insert with the designation "CCGT" is a high positive ground insert primarily intended for use with aluminum but "can" be used with steel and SS. The insert the OP linked to above is a CCGT intended for use with steel. The difference between this CCGT insert and the high positive rake CCGT inserts intended for use with aluminum is the CHIPBREAKER. The very high positive rake chip breaker on a CCGT insert intended for use with aluminum is usually designated as an AK or H01 chip breaker; on the insert the OP used, the chipbreaker is a CK and it is a finishing insert for steel.

I totally get using carbide inserts so you can learn to use your lathe. Many, if not most, hobby guys start out this way but you are going to find that HSS holds so many advantages that it is well worth taking the time to learn to grind a tool. I took a look back in your postings and you are using a tiny mini-lathe that is totally unsuitable for use with carbide tooling. It doesn't have the speed, power or rigidity required for use with carbide tooling so you are really setting yourself up for a hard time. Do yourself a big favor and start using HSS. Tool grinding isn't hard to learn and if you need some tools to get started while you are learning to grind your own, I know a few guys who can grind them for you for a reasonable price. With care, a HSS tool will last for a decade or more so you'll have time to learn to do it on your own.