- Joined

- Sep 1, 2018

- Messages

- 74

There is rebuilding, refurbishing and cleanup.

One must understand what the end result will be with each option to consider return on investment.

A South Bend with worn ways will be different than one without but consider the real difference in cut.

Cutting at center and lowering tool as a worn way and the difference in depth of cut is minimal.

Rigidity and other features of any lathe when new limit how good it can be.

Lipstick on a pig is a good line here.

A worn but cleaned up South Bend works almost as good as the exact same machine when new in proper hands.

It may be better to tear down and clean all then paint and tune to adjust ships and gibs.

The money saved can be used for tooling or put aside for the next machine...and there will be...on lathe 9 or so and was not even looking for last one...

Sent from my SAMSUNG-SM-G930A using Tapatalk

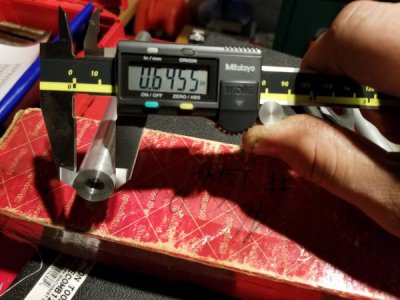

Is there a way to give me a little more insight as to what you mean ? My primary use will be gunsmithing. So let`s say I have a Rem700 1" dia. bull barrel I need to thread for a compensator(last 1/2" of barrel). I have 8" sticking out of the chuck and 16" in the spindle being supported by a spider. I`m also using a steady rest because I`m way past my 2x dia............. Because of one reason or another that is the only way to place the work in the machine. At that same point is heavy wear in the bed and the carriage drops A LOT(.125). What would I do to compensate for that drop in the bed ? All hypothetical of course but could easily be a real world scenario..My threads would destroyed no ? If I tighten the gibs I can`t move the carriage back for the next pass. I`m so new to this that I don`t even know how far off I am in this scenario ? LOL....What do I do ?? I`m trying to get a visual as to what you could do ? Thanks, AJ