- Joined

- Dec 22, 2023

- Messages

- 123

I am going to make a new dual v belt sheave for my new to me Logan lathe. I have an 5" diameter aluminum biscuit, 3" long. I chucked it up in my 4 jaw but am wondering where I should be indicating - at the end nearest the chuck, the middle or the end farthest from the chuck?

Also, order of operations? I thought I would chuck it as close as I could in the 4 jaw for run out,

face the end,

Center drill and drill the (undersize) mounting hole.

Rough the sheave form pretty close to final dimensions, maybe .030 over size.

Ream the center hole to final diameter.

Cut the key way in the bore.

Mount the sheave to an arbor/mandrel.

Do the final machining on the belt grooves.

Oh, and Merry Christmas to everyone!!

Also, order of operations? I thought I would chuck it as close as I could in the 4 jaw for run out,

face the end,

Center drill and drill the (undersize) mounting hole.

Rough the sheave form pretty close to final dimensions, maybe .030 over size.

Ream the center hole to final diameter.

Cut the key way in the bore.

Mount the sheave to an arbor/mandrel.

Do the final machining on the belt grooves.

Oh, and Merry Christmas to everyone!!

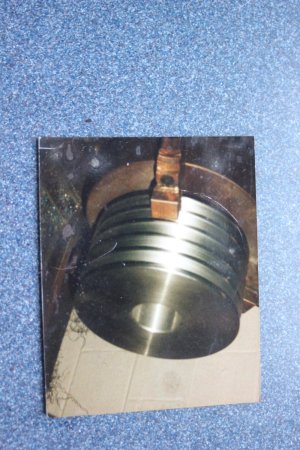

Found some pics of some that I shipped out to Cali for a breakdown . Done on my first lathe . 1760 Voest .

Found some pics of some that I shipped out to Cali for a breakdown . Done on my first lathe . 1760 Voest .