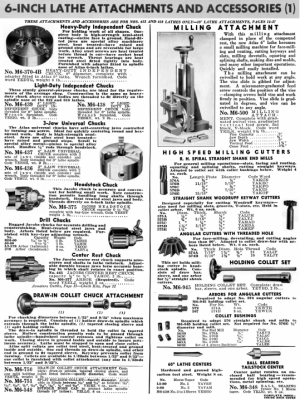

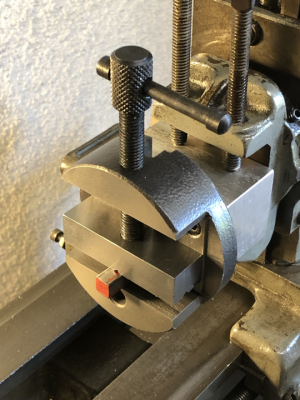

I picked up a milling attachment for my Atlas 10100 Mk.2 and am about to make some of the sleeves to adapt the holder for different size in endmill shanks. I've seen it written that the weldon shank endmills are NOT to be used with a sleeve using the set screw on the flat as it may sieze the endmill in the holder. After searching and watching several videos I'm a bit confused as to why ?? The information I keep turning up advises not using a chuck (3 or 4 jaw, drill chuck) as both the endmill and chuck jaws are hardened, and so won't grip reliably and the endmill can draw itself out of the chuck while in use.

The milling attachment endmill holder for the Mk.2 has a set screw provided for what I assume is to engage the flat on the weldon style endmill shanks. The original setup also included IIRC 4 adapter sleeves (mine were missing) for use of smaller than 0.500 endmill shanks. If the weldon shank endmills were meant to be used with this holder and it's included adapter sleeves why all the warning not to do so ?? What I'm struggling to understand is if a regular 3 or 4 jaw chuck cannot reliably hold the endmill due to both the jaws and endmill being hardened, and I'm supposed to ensure that the slotted shank weldon endmills are not lined up with the set screw in the endmill holder adapters...then what exactly is supposed to be holding the endmill in place when all you have for retention is a set screw bearing against a smooth hardened shank instead of the slot cut into the weldon shank endmill which would allow the set screw to bear against the flat locking the endmill in place. What am I missing here...??

If the weldon style endmill shanks WERE NOT meant to be used with this endmill holder then what is providing the retaining force keeping the endmill in place instead of allowing it to draw itself out of the holder while in operation similar to what is said to happen if an endmill is used in a chuck ??

It's a bit hard to grasp how a smooth shank hardened endmill could be locked firmly in place by a single set screw so that it wouldn't rotate in the endmill holder in operation when the clamping force of a 4 jaw chuck isn't up to the task from what I've read.

Here's a mr. pete video where he talks about thsi at the 6:40 mark...

9

The milling attachment endmill holder for the Mk.2 has a set screw provided for what I assume is to engage the flat on the weldon style endmill shanks. The original setup also included IIRC 4 adapter sleeves (mine were missing) for use of smaller than 0.500 endmill shanks. If the weldon shank endmills were meant to be used with this holder and it's included adapter sleeves why all the warning not to do so ?? What I'm struggling to understand is if a regular 3 or 4 jaw chuck cannot reliably hold the endmill due to both the jaws and endmill being hardened, and I'm supposed to ensure that the slotted shank weldon endmills are not lined up with the set screw in the endmill holder adapters...then what exactly is supposed to be holding the endmill in place when all you have for retention is a set screw bearing against a smooth hardened shank instead of the slot cut into the weldon shank endmill which would allow the set screw to bear against the flat locking the endmill in place. What am I missing here...??

If the weldon style endmill shanks WERE NOT meant to be used with this endmill holder then what is providing the retaining force keeping the endmill in place instead of allowing it to draw itself out of the holder while in operation similar to what is said to happen if an endmill is used in a chuck ??

It's a bit hard to grasp how a smooth shank hardened endmill could be locked firmly in place by a single set screw so that it wouldn't rotate in the endmill holder in operation when the clamping force of a 4 jaw chuck isn't up to the task from what I've read.

Here's a mr. pete video where he talks about thsi at the 6:40 mark...

9