- Joined

- Dec 27, 2014

- Messages

- 4,093

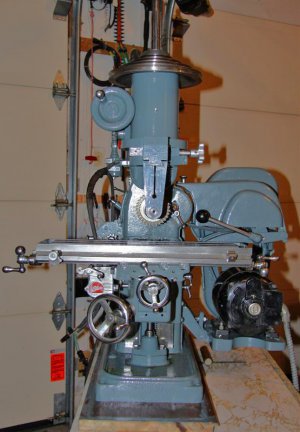

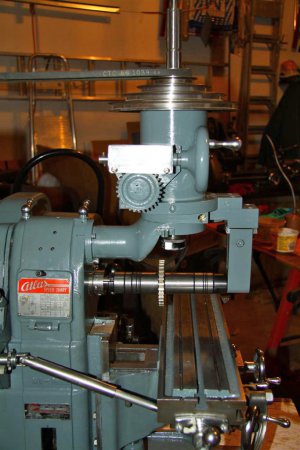

I ran a horizontal (don't remember it's name) for years, converted to CNC. I had a 12" angle plate which I used much of the time. In use the operator stood behind the table to the machine's left, facing the table. (wish I could remember what it was called, I'd only seen that one machine. It had been modified extensively, once had two spindles, side by side, operated independently, with a provision to move from one to the other. That was before I was put on it.

In any case, it was far more stable than any Bridgeport type machine, capable of the same sort of work, and you could watch the tooling 100%.

In any case, it was far more stable than any Bridgeport type machine, capable of the same sort of work, and you could watch the tooling 100%.