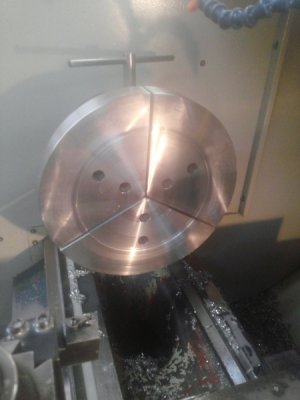

I can't recall using soft jaws myself. I have seen others use them. Ussually they were used in conjunction with a medium size production run. I think they were bored a little smaller than the OD of the part so the outer edges gripped the part diameter so there would be six points of contact. I think the machinist used a steel ring. The ring was placed over the soft jaws. Then they were expanded to hold the ring tight leaving the inside clear to be bored out to size. I saw something the looked like a three sided star shape that the jaws could be tightened down on so the outer diameter of the jaws could be turned to size if the part needed be held by its inside diameter. I hope I have explained it clearly, I can see it in my mind but sometimes putting it in words is hard.

Its been a long time since I worked in that shop. One thing for sure that interrupted cut is hard on the tool bit.

Its been a long time since I worked in that shop. One thing for sure that interrupted cut is hard on the tool bit.