@7milesup

First, I want to say that I don't remember ever seeing a bandsaw wheel that wasn't crowned and didn't have a tire. However, I don't consider myself an expert. Just another contributor.

Assuming the blade teeth are positioned nearest the groove/flange, I think the groove, on this wheel, is there to clear the blade kerf. I don't anticipate any problem with that. It should work just fine if you make sure the groove is deep/wide enough for the blades you use.

If the OEM parts manual doesn't show a tire, I guess the saw doesn't use a tire. If it works well, acquiesce to the OEM designers.

This class of saw has very short distance between the blade guides and the wheel tangents, so not having a crown or an elastomeric tire may work just fine.

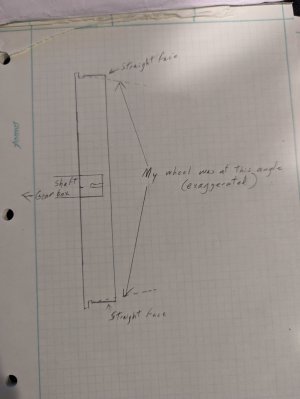

The taper (cone) you represented, in the sketch, looks like a problem to me. It sounds like the wheel OD is now essentially cylindrical. If it works well, IMO, declare a victory and move on. If the blade teeth create tracks in the groove (or adjacent), the The groove needs to be deeper/wider and the blade guides need to be properly adjusted.