-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

POTD- PROJECT OF THE DAY: What Did You Make In Your Shop Today?

- Thread starter wachuko

- Start date

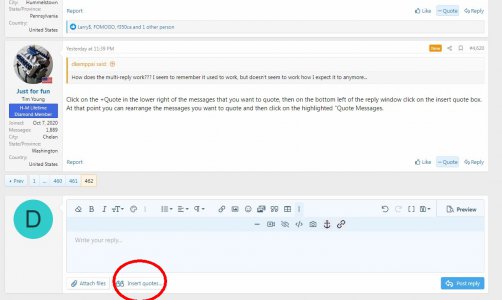

I must be dense... Where's the insert quote button? When I click the "Quote", after having selected multiple messages with the "+quote" button, next to videos and table, all I get is a blank quote...

View attachment 461988

Hit +quote on each item that you want to quote

Then go to the blank reply window and hit insert quotes

Yep, like I said. Dense... lol!

Thanks.

I finally got tired of the way the Carriage Lock operates on my Mini-Lathe. A little background: shortly after I got a Carriage Lock from Little Machine Shop, I modified it (of course) – as designed, it mounts to the Carriage using the holes intended for a Follower Rest (and Yes, I replaced the clunky re-positionable lever with a smaller one soon after I did the original installation):

It was better than nothing, but couldn't be reached if you were working close to the Head Stock; plus I wanted to use those holes for a Swarf Shield:

The shield on the left has embedded magnets to hold it against the Head Stock and a "wiper" that the shield attached to the Carriage passes under. I made several sizes of the Carriage-mounted shields to suit varying length workpieces. To make this possible, I modified the Carriage Lock and moved it to the other side of the Carriage:

This worked well, but due to the Gib Adjusting Screws (and an M4 Hex Screw I use in an added tapped hole to lock the Cross-Slide) there wasn't room for a lever, so I substituted an M6 SHCS. The only issue with this was when I was using a center in the Tail Stock the SHCS was blocked. On even slightly larger lathes there is the possibility of adding a lock in the Apron area, but not a lot of space on a Mini-Lathe, so I put up with what I had. A couple of weeks ago I thought of an answer, and finally made it this morning:

1144 Stressproof: M6-1.0 on one end, a 3mm thick shoulder and a 5mm hex on the other; paired with an inexpensive 5mm, 12-point combination wrench and Voila:

The Carriage goes from free moving to locked with just a flick of the wrench!

This was my first experience with 1144: it machines beautifully, even on my Mini-Lathe & Mini-Mill. However, it made me remember why I like working in Aluminum & Brass: Cutting Oil, Hot Chips & Magnetic Chips – it takes three times as long to clean up!!

It was better than nothing, but couldn't be reached if you were working close to the Head Stock; plus I wanted to use those holes for a Swarf Shield:

The shield on the left has embedded magnets to hold it against the Head Stock and a "wiper" that the shield attached to the Carriage passes under. I made several sizes of the Carriage-mounted shields to suit varying length workpieces. To make this possible, I modified the Carriage Lock and moved it to the other side of the Carriage:

This worked well, but due to the Gib Adjusting Screws (and an M4 Hex Screw I use in an added tapped hole to lock the Cross-Slide) there wasn't room for a lever, so I substituted an M6 SHCS. The only issue with this was when I was using a center in the Tail Stock the SHCS was blocked. On even slightly larger lathes there is the possibility of adding a lock in the Apron area, but not a lot of space on a Mini-Lathe, so I put up with what I had. A couple of weeks ago I thought of an answer, and finally made it this morning:

1144 Stressproof: M6-1.0 on one end, a 3mm thick shoulder and a 5mm hex on the other; paired with an inexpensive 5mm, 12-point combination wrench and Voila:

The Carriage goes from free moving to locked with just a flick of the wrench!

This was my first experience with 1144: it machines beautifully, even on my Mini-Lathe & Mini-Mill. However, it made me remember why I like working in Aluminum & Brass: Cutting Oil, Hot Chips & Magnetic Chips – it takes three times as long to clean up!!

Cleaning the big garage continues today, early this morning while i was still full of energy i moved all the engines from one side to the other except for one, i plan to get that one running. I also found a tubing bender i made like 20 years ago. The bottom of the new shelf is now full of engines, i hoped to have finished cleaning by now because i have cars needing work done but if i put this off it will have to wait for a full year at least.

Finishing up the new PC. Needed to add one small hole in the case. Was a hard spot to reach into, so I cheated.

Have done this several times before. It works really well, but looks so wrong!

Also got rid of the Pool. It's now the "Pool That Is No More". Banded it to a pallet, collected all the chemicals, and gave it to a friend of the family who was interested in it. The only things left to do are clean up the pad of sand, a little bit of landscaping and add topsoil and seed.

Somewhere in between the dog melted into a sunbeam. Not sure how she can live with herself, spending one of the last sunny days just lazing around. Maybe there's a lesson here...

Have done this several times before. It works really well, but looks so wrong!

Also got rid of the Pool. It's now the "Pool That Is No More". Banded it to a pallet, collected all the chemicals, and gave it to a friend of the family who was interested in it. The only things left to do are clean up the pad of sand, a little bit of landscaping and add topsoil and seed.

Somewhere in between the dog melted into a sunbeam. Not sure how she can live with herself, spending one of the last sunny days just lazing around. Maybe there's a lesson here...

The whole evening, all that was accomplished was this.

It's the ends of two 30m fiber pairs, fished through an existing wall, into the basement via the attic, to the network 'closet'. One will run 1.25G for the main network, and the other will be a 10G drop to the FreeNAS box.

And this was all the leftover! (The aqua ones, not plugged in yet) That was close!

Only problem is I long ago ran out of SFP ports in the switch. So could really use a 10G SFP+ switch, but they ain't cheap! There are plenty of PCIe slots in the FreeNAS box for more dual SFP+ NICs. Might be cheaper to drop an extra NIC in the FreeNAS box and bridge them. (Throughput and latency through bridged connections are pretty poor for the 10G in that box tho...) But, that's a problem for another night.

It's the ends of two 30m fiber pairs, fished through an existing wall, into the basement via the attic, to the network 'closet'. One will run 1.25G for the main network, and the other will be a 10G drop to the FreeNAS box.

And this was all the leftover! (The aqua ones, not plugged in yet) That was close!

Only problem is I long ago ran out of SFP ports in the switch. So could really use a 10G SFP+ switch, but they ain't cheap! There are plenty of PCIe slots in the FreeNAS box for more dual SFP+ NICs. Might be cheaper to drop an extra NIC in the FreeNAS box and bridge them. (Throughput and latency through bridged connections are pretty poor for the 10G in that box tho...) But, that's a problem for another night.

Took a break from tools . 1 log .....3 days ! 12' x 49" diameter oak log has been sitting in the back yard for 2 years . Now cut , split and residing on the back patio ready for the woodstove this winter . My body hurts .