tq60 --> Yes, aluminium. Melted it myself into round stock.

This is the result of my investigation:

First the chirping sound . . . disengaged the lead screw drive train,-still chirping.

Removed the belt,- same thing.

There are two belt pulleys at the motor end. One for the low speed range and another for the high speed range.

I pulled the low speed pulley and the axle was bone dry and covered with brown dust.

Ran the lathe without the pulley and the chirping went away.

The lathe was purchased not long ago and hasn't been used more than a few hours so the workers that put it together didn't bother to lube the thing.

I put on some grease, mounted the pulley and no noise when running.

Problem solved.

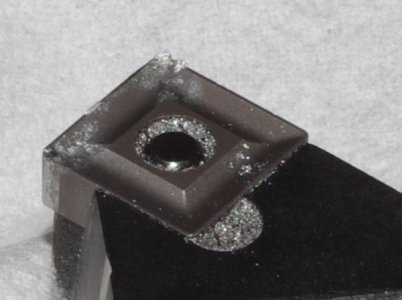

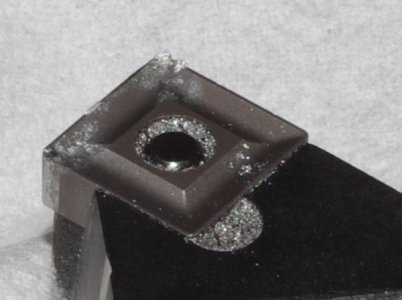

As for the poor finish I cleaned the insert and had a close look at the tip (see image).

Looks like build up after turning aluminium dry.

Turned the insert around, and I still don't get a mirror finish, but it is at least consistent and the lathe runs effortlessly.

This is a step forward, and the next steps are correct rpm, correct DOC, correct feed rate, casting round stock out of known good aluminium known to machine well.

This is the result of my investigation:

First the chirping sound . . . disengaged the lead screw drive train,-still chirping.

Removed the belt,- same thing.

There are two belt pulleys at the motor end. One for the low speed range and another for the high speed range.

I pulled the low speed pulley and the axle was bone dry and covered with brown dust.

Ran the lathe without the pulley and the chirping went away.

The lathe was purchased not long ago and hasn't been used more than a few hours so the workers that put it together didn't bother to lube the thing.

I put on some grease, mounted the pulley and no noise when running.

Problem solved.

As for the poor finish I cleaned the insert and had a close look at the tip (see image).

Looks like build up after turning aluminium dry.

Turned the insert around, and I still don't get a mirror finish, but it is at least consistent and the lathe runs effortlessly.

This is a step forward, and the next steps are correct rpm, correct DOC, correct feed rate, casting round stock out of known good aluminium known to machine well.

Last edited: