- Joined

- Sep 10, 2013

- Messages

- 594

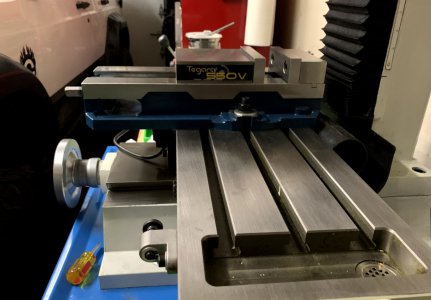

I like my PM932m PDF. Only thing is the motor and oil seals suck. The spindle seal has leaked oil from day one. And the motor lasted about 20 hr of run time. It now has a metric motor with a VFD. It runs quieter smother and I can now run carbide tooling. I can power tap within reason of coarse, and have not broken a tap in a long time, and now with the tapping head it is very useful. The head seals still leaks and I have to clean oil up every time I use it, but it gets the job done. The finish it great and with the DRO Pros it is a good hobby mill and don’t take up a lot room. I would go with Taiwan mill.

CH

CH