I recently purchased a PM1236T and brought it into my basement through a Bilco entryway door and thought I would document it here for anyone else considering such a move.

I had a 9x20 lathe for many years and wanted to upgrade it, so sold it a few years ago planning on purchasing a replacement, but life got in the way and I finally got the new lathe last December. Following is a series of photos of how I got it from my garage and into the basement. I also built my own stand for it instead of purchasing the PM one.

Here is the customary picture of the crate as it arrived. The driver from ABF was great and moved it into my garage on his pallet jack.

I called a fellow member of a business association I am in to see how much it would cost his moving company to move the lathe from my garage and into the basement. I’m glad I was sitting down when I got that estimate, minimum charge $800 and it could be more. That would be a hard no!

I moved my Burke Millrite into my basement by placing the main casting on a skid and hiring a local towing company to use their flatbed to lower it down the stairs at the Bilco entry door. That worked well, so I decided to the the same with the lathe. Since the lathe was already on a pallet that looked suitable with some modifications, first order of business was get it off the lower shipping pallet. My engine hoist was not wide enough to get in far enough to lift it, so I used my car floor jack to get underneath and the cut out pallet piece by piece and put up on blocks so I could make my modifications.

Once the main pallet was up on blocks, I moved the cross risers from the bottom to the top to maintain the strength they added to the pallet and giving me runners on the bottom that could be used to when sliding it down the stairs.

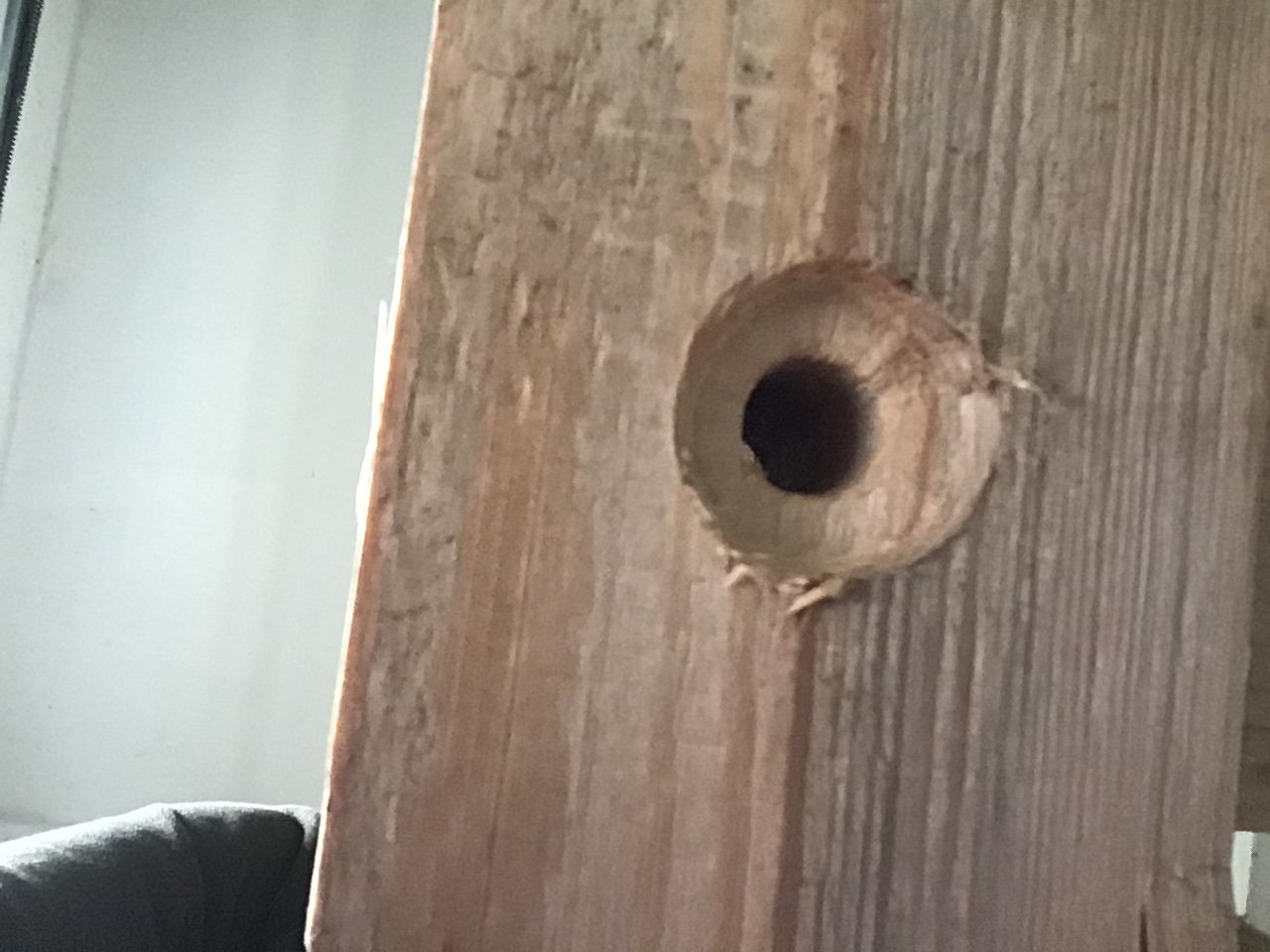

The carriage bolt heads were sitting proud of the bottom runners and I was concerned that would make it more difficult to slide, so I used a spade drill sharpened on the backside to counterbore the holes by inserting the drill from the bottom and then drilling from the top. This worked FAR better than I anticipated. It’s nice when something works better than you imagine.

I was concerned there would be too much stress for the bottom runners when the skid tips from the end of the flatbed to the stairs, so I added some wood between the skid and the lathe in the center to give it more rigidity. Apparently I did not take a picture of that, but imagine blocking about midway along the lathe length that closes the gap between the lathe and skid.

I was concerned there would be too much stress for the bottom runners when the skid tips from the end of the flatbed to the stairs, so I added some wood between the skid and the lathe in the center to give it more rigidity. Apparently I did not take a picture of that, but imagine blocking about midway along the lathe length that closes the gap between the lathe and skid.

Next post will have pictures of bringing it into the basement.

I had a 9x20 lathe for many years and wanted to upgrade it, so sold it a few years ago planning on purchasing a replacement, but life got in the way and I finally got the new lathe last December. Following is a series of photos of how I got it from my garage and into the basement. I also built my own stand for it instead of purchasing the PM one.

Here is the customary picture of the crate as it arrived. The driver from ABF was great and moved it into my garage on his pallet jack.

I called a fellow member of a business association I am in to see how much it would cost his moving company to move the lathe from my garage and into the basement. I’m glad I was sitting down when I got that estimate, minimum charge $800 and it could be more. That would be a hard no!

I moved my Burke Millrite into my basement by placing the main casting on a skid and hiring a local towing company to use their flatbed to lower it down the stairs at the Bilco entry door. That worked well, so I decided to the the same with the lathe. Since the lathe was already on a pallet that looked suitable with some modifications, first order of business was get it off the lower shipping pallet. My engine hoist was not wide enough to get in far enough to lift it, so I used my car floor jack to get underneath and the cut out pallet piece by piece and put up on blocks so I could make my modifications.

Once the main pallet was up on blocks, I moved the cross risers from the bottom to the top to maintain the strength they added to the pallet and giving me runners on the bottom that could be used to when sliding it down the stairs.

The carriage bolt heads were sitting proud of the bottom runners and I was concerned that would make it more difficult to slide, so I used a spade drill sharpened on the backside to counterbore the holes by inserting the drill from the bottom and then drilling from the top. This worked FAR better than I anticipated. It’s nice when something works better than you imagine.

Next post will have pictures of bringing it into the basement.