I was wrong. I just went to my mill and measured the OD of the flexible tubing to be about 0.44 inch. This is smaller than what is at Heyco or McMaster. Their smallest OD is .57 (what they call a Trade size of 1/4) so the connectors must be different as well. If we cannot find the same match, we will have to change the conduit, connectors, and make the holes larger in the motor electrical feed box and the main/big control electrical box.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pm-940m-cnc (pre-assembled)

- Thread starter fugawii

- Start date

I am sure it is metric. PM 940M VS CNC . My first mill ever. However, my quick searches do not yield the flex tubing in metric .... I left a picture of it on another Thread. https://www.hobby-machinist.com/threads/pm-940m-cnc.76539/

Thanks for your help. Going to have to give this a rest. Its time to get organized for taxes! Milling is more interesting,

Thanks for your help. Going to have to give this a rest. Its time to get organized for taxes! Milling is more interesting,

Hi Megaplow,

I am interested, but having a lot of trouble trying to find a true replacement of what is on my machine: flexible, steel covered with plastic and small OD etc. I have not tried calling PM yet to see if they could just get some of the conduit for us, but will wait to hear back from you. Do you have the same conduit as I (see below)? Is this what you want/need? PM does seem to stock items which are not mentioned on their web site so maybe they have the conduit or can get it with their next shipment from China!

I looked at your Mill pics. Your PM 940M VS CNC looks similar if not identical to mine pre your reworks, so it probably had the same conduits. I, rotated by 180 degrees, and mounted my electrical cabinet on the right side of the Mill vertical post rather than the wall. The room size is small so I put my mill stand on dolly wheels so that I can move the whole thing short distances if I want to. I measured the OD on the conduit to the x-stepper. While it is soft plastic I think the OD is 0.435 to 0.440" and has about per 5mm rib spacing. This would be about 11mm OD. However, after looking around on the web, I think this might be what is call as 12mm nominal. Mine is steel reinforced making the inside smaller. I even looked on Aliexpress.com and Alibaba.com but did not really have any luck. Aliexpress has lot of flexible conduit priced inexpensively, but I do not think any of them have steel inside...just plastic tubing. I am not for sure what the plastic is composed of, but it should be oil resistant? I have seen multiple compositions, but the most common is PVC which is not solvent resistant but is water proof. Alas I keep looking. The closest looking product I have found is priced in British Pounds and is about $78 US plus tax and shipping for a 25 meter roll. Check it out: https://uk.rs-online.com/web/p/conduit/7840094/ The good thing is that Allied is a supplier in the states so shipping would not be so much:

However, again this is PVC.

However, again this is PVC.

Given that you are in CA and I am in PA and that shipping will probably be a significant portion of the cost, it may make more sense for each of us to purchase separately.

Lastly, I have some extra conduit pieces of various lengths... heavy duty flexible liquid proof steel, but bends. It is great stuff and I do not have a burning need. If I knew what you needed maybe some of it would help you out. I did use a piece of it to reconnect the E-stop box. When the controls were on the back the distance from cabinet to E-stop was short. It is about the same diameter as the conduit used on the lamp, but is much heavier and a little more flexible. The connectors are not metric and so I had to make a thread adapter to connect to the E-stop arm. Anyway, if any of them would work for you it would be good. I do not know what shipping would cost you, but after you know what you need I could see if I have a piece and if so I could weight it.

Dave

I am interested, but having a lot of trouble trying to find a true replacement of what is on my machine: flexible, steel covered with plastic and small OD etc. I have not tried calling PM yet to see if they could just get some of the conduit for us, but will wait to hear back from you. Do you have the same conduit as I (see below)? Is this what you want/need? PM does seem to stock items which are not mentioned on their web site so maybe they have the conduit or can get it with their next shipment from China!

I looked at your Mill pics. Your PM 940M VS CNC looks similar if not identical to mine pre your reworks, so it probably had the same conduits. I, rotated by 180 degrees, and mounted my electrical cabinet on the right side of the Mill vertical post rather than the wall. The room size is small so I put my mill stand on dolly wheels so that I can move the whole thing short distances if I want to. I measured the OD on the conduit to the x-stepper. While it is soft plastic I think the OD is 0.435 to 0.440" and has about per 5mm rib spacing. This would be about 11mm OD. However, after looking around on the web, I think this might be what is call as 12mm nominal. Mine is steel reinforced making the inside smaller. I even looked on Aliexpress.com and Alibaba.com but did not really have any luck. Aliexpress has lot of flexible conduit priced inexpensively, but I do not think any of them have steel inside...just plastic tubing. I am not for sure what the plastic is composed of, but it should be oil resistant? I have seen multiple compositions, but the most common is PVC which is not solvent resistant but is water proof. Alas I keep looking. The closest looking product I have found is priced in British Pounds and is about $78 US plus tax and shipping for a 25 meter roll. Check it out: https://uk.rs-online.com/web/p/conduit/7840094/ The good thing is that Allied is a supplier in the states so shipping would not be so much:

Given that you are in CA and I am in PA and that shipping will probably be a significant portion of the cost, it may make more sense for each of us to purchase separately.

Lastly, I have some extra conduit pieces of various lengths... heavy duty flexible liquid proof steel, but bends. It is great stuff and I do not have a burning need. If I knew what you needed maybe some of it would help you out. I did use a piece of it to reconnect the E-stop box. When the controls were on the back the distance from cabinet to E-stop was short. It is about the same diameter as the conduit used on the lamp, but is much heavier and a little more flexible. The connectors are not metric and so I had to make a thread adapter to connect to the E-stop arm. Anyway, if any of them would work for you it would be good. I do not know what shipping would cost you, but after you know what you need I could see if I have a piece and if so I could weight it.

Dave

My 940 cnc has the same conduit, however the ends are just regular old strain relief cord grips (cable glands) with the rubber grip part removed. I don't see why you couldn't just remove the current wires and replace them with some SJOOW or SOOW cable (extension cord stuff rated for oil). 50' will give you a bunch left over after you re-wire the steppers.

FYI the difference between SJOOW and SOOW is the voltage rating. SJOOW is 300v and SOOW is 600v, so SOOW has much thicker insulation making the overall diameter of the wire much larger.

PZ

eBoot Plastic Waterproof Adjustable 3.5-13mm Cable Glands Joints, PG7, PG9, PG11, PG13.5, PG16, Pack of 20 - - Amazon.com

eBoot Plastic Waterproof Adjustable 3.5-13mm Cable Glands Joints, PG7, PG9, PG11, PG13.5, PG16, Pack of 20 - - Amazon.com

www.amazon.com

Amazon.com: Custom Cable Connection 16/4 SOOW 16 AWG 4 Conductor 600 Volt Portable Power Cable - 25 Foot Roll in a Bag: Home Audio & Theater

Buy Custom Cable Connection 16/4 SOOW 16 AWG 4 Conductor 600 Volt Portable Power Cable - 25 Foot Roll in a Bag: Electrical Wire - Amazon.com ✓ FREE DELIVERY possible on eligible purchases

www.amazon.com

Amazon.com: Custom Cable Connection 50 Foot - SJOOW 16 AWG 4 Conductor 300V Portable Power Cable - 50 Foot Roll in a Bag: Home Improvement

Buy Custom Cable Connection 50 Foot - SJOOW 16 AWG 4 Conductor 300V Portable Power Cable - 50 Foot Roll in a Bag: Electrical Wire - Amazon.com ✓ FREE DELIVERY possible on eligible purchases

www.amazon.com

FYI the difference between SJOOW and SOOW is the voltage rating. SJOOW is 300v and SOOW is 600v, so SOOW has much thicker insulation making the overall diameter of the wire much larger.

PZ

Hi PZ,

Thanks. Another wire option is good! I kind of like the look of the flexible conduit and have managed to stay with the original size on my 940M up until now. If possible I would prefer not to have to resize the holes in the connector boxes or have a kludge connector. Anyway, my problem is not too severe, the x-axis cable is just a bit short and so as you can see the cable at the connector broke when I ran the x-axis near the the full swing.

I have been reading some of your other posts and enjoying them and the photos. I was following your belt drive and the Acorn conversions. Thanks.

If you do not mine I have a couple of questions about your other posts? If it is too much, please just say so.

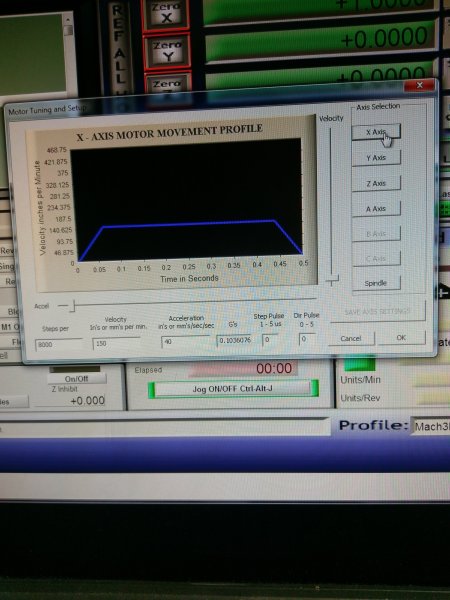

1) I am still running the nMotion/Mach3 and it does not seem to be all that bad so maybe I will hold off on the Acorn upgrade for a while. When my machine came with the initial nMotion setup code it had the three axis max velocities set to x, y, z = 50, 40, 20 in/min and 8000 steps per (inch). I think in one post that you talked about the maximum velocities you could get out of your machine. I know mine will go a lot higher, but how did you determine the limit? Was it determined at the velocity where motor steps were missed and and so might not return to the same location. If so is this not highly dependent upon the load? (I had assumed that was why the factory set it up at 50, 40, 20. The y stage is stacked under the x stage so it must accelerate and move more mass. y has to move all of the mass of x stage plus its own mass and friction. The z axis head is just very heavy so it is not simply the inertia that has to be accounted for, but gravity. I did a poor man's weight measurement of the z axis stage etc and got over 250 #s. )

2) I recently made a bunch of x-y plane 8-9" radius cuts over ~180 degrees and it all worked very well and repeatable, but the machine was kind of noisy when both x and y are swinging. I was running at about 30in/min. I was cutting plywood for a "honey do" project so the cutting speed was not a big issue. While I find the limited documentation to be troubling, I have had few problems with nMotion. Maybe I am just not experienced enough, but if my machine is running "OK", what do I gain by changing over to Acorn. Is the motion a lot smoother? Maybe the software is just easier to use?

3) In your spindle motor and belt drive conversion.... maybe you want to post the answer on that forum rather than here. I could not find where you mentioned the details/models of your motor and driver. Could you do so? (Maybe just a picture of the motor and driver labels.) Also could you post your Fusion 360 code that your wrote when you drew up the nice schematic of the 940 spindle head? Having this could be handy.

4) In the photo it looks like with your new DC spindle servo motor will have the encoder on the motor, not the spindle. Do you think with the belt drive you would be able to do rigid tapping? Does the Hobby version of Acorn and software provide for rigid tapping? G84? It does not seem that Mach3 provides for G84 since in the documentation the description of G84 is a faded font. Likewise, at Centroid, the comparison page of controller boards mentions rigid tapping for the more expensive boards, but not for Acorn. Anyway, I suppose if a mill had the mechanical capability of accurate spindle speed and phase control and can reverse without excessive back lash, which your might after the conversion, then you might be able to write G-code to mimic G84. I was thinking about trying to build an auxiliary stepper hanging off the side of the head assembly directly driving the spline via tooth belt drive. The idea would be to disengage the normal spindle gears by turning the gear/speed select nob midway between speed 1 and 2 and then driving the spline via the stepper. I thought I might be able to use the 4th axis motor and driver for this drive. I suppose one could just replace the current 3phase drive motor with a servo system, but the current head gears have about 1.25 +-.25 degree back-lash at the spindle.

Thanks.

Dave

Thanks. Another wire option is good! I kind of like the look of the flexible conduit and have managed to stay with the original size on my 940M up until now. If possible I would prefer not to have to resize the holes in the connector boxes or have a kludge connector. Anyway, my problem is not too severe, the x-axis cable is just a bit short and so as you can see the cable at the connector broke when I ran the x-axis near the the full swing.

I have been reading some of your other posts and enjoying them and the photos. I was following your belt drive and the Acorn conversions. Thanks.

If you do not mine I have a couple of questions about your other posts? If it is too much, please just say so.

1) I am still running the nMotion/Mach3 and it does not seem to be all that bad so maybe I will hold off on the Acorn upgrade for a while. When my machine came with the initial nMotion setup code it had the three axis max velocities set to x, y, z = 50, 40, 20 in/min and 8000 steps per (inch). I think in one post that you talked about the maximum velocities you could get out of your machine. I know mine will go a lot higher, but how did you determine the limit? Was it determined at the velocity where motor steps were missed and and so might not return to the same location. If so is this not highly dependent upon the load? (I had assumed that was why the factory set it up at 50, 40, 20. The y stage is stacked under the x stage so it must accelerate and move more mass. y has to move all of the mass of x stage plus its own mass and friction. The z axis head is just very heavy so it is not simply the inertia that has to be accounted for, but gravity. I did a poor man's weight measurement of the z axis stage etc and got over 250 #s. )

2) I recently made a bunch of x-y plane 8-9" radius cuts over ~180 degrees and it all worked very well and repeatable, but the machine was kind of noisy when both x and y are swinging. I was running at about 30in/min. I was cutting plywood for a "honey do" project so the cutting speed was not a big issue. While I find the limited documentation to be troubling, I have had few problems with nMotion. Maybe I am just not experienced enough, but if my machine is running "OK", what do I gain by changing over to Acorn. Is the motion a lot smoother? Maybe the software is just easier to use?

3) In your spindle motor and belt drive conversion.... maybe you want to post the answer on that forum rather than here. I could not find where you mentioned the details/models of your motor and driver. Could you do so? (Maybe just a picture of the motor and driver labels.) Also could you post your Fusion 360 code that your wrote when you drew up the nice schematic of the 940 spindle head? Having this could be handy.

4) In the photo it looks like with your new DC spindle servo motor will have the encoder on the motor, not the spindle. Do you think with the belt drive you would be able to do rigid tapping? Does the Hobby version of Acorn and software provide for rigid tapping? G84? It does not seem that Mach3 provides for G84 since in the documentation the description of G84 is a faded font. Likewise, at Centroid, the comparison page of controller boards mentions rigid tapping for the more expensive boards, but not for Acorn. Anyway, I suppose if a mill had the mechanical capability of accurate spindle speed and phase control and can reverse without excessive back lash, which your might after the conversion, then you might be able to write G-code to mimic G84. I was thinking about trying to build an auxiliary stepper hanging off the side of the head assembly directly driving the spline via tooth belt drive. The idea would be to disengage the normal spindle gears by turning the gear/speed select nob midway between speed 1 and 2 and then driving the spline via the stepper. I thought I might be able to use the 4th axis motor and driver for this drive. I suppose one could just replace the current 3phase drive motor with a servo system, but the current head gears have about 1.25 +-.25 degree back-lash at the spindle.

Thanks.

Dave

I defiantly don't mind responding with my $0.02.

1.) I locked a part in the vice that was about as large as I figured I would ever machine and then created a program in Fusion 360 that mimicked moves I figured I would make (LOTS of adaptive). Then I ran it, adjusted velocity, and accel. I repeated this several times until I got it locked down with no missing steps. I got some very low numbers with the nMotion, but with the Acorn I'm at 100ipm in the x and y, and 65ipm in the z. One thing that GREATLY contributes to stepper noise and missed steps is "smoothing" always use it in Fusion adaptive processes. Even truing it to 0.0005" makes a HUGE difference. Acorn also has smoothing built in, once I turned that on, things got even better. After all of this was said and done, and I ran a few parts I realized that missing steps is more often than not related to bad programming. Asking the controller to process 200 lines of G code to go around a 0.5" radius makes no sense. The "noise" comes from the stepper constantly changing speed going though an arc.. and adaptive moves will do it all the time, so be careful.

2.) I kinda answered this with #1, but SMOOTHING! Turn smoothing on and run the same path again and see what it does. What you gain by going to the Acorn is mostly piece of mind, but there are also things like built in smoothing, great documentation, and their only tech support (fourm) is great. The nMotion/M3 can get the job done, but it's not the quality I was looking for. When I realized the estop circuit was a normally open circuit, that was kinda the icing on the cake for me. I take safety very seriously and a normally open estop circuit is a HUGE no, no. If they cut that very simple corner, where else did they cut corners? Like I said, nMotion and M3 will get it done, but I like piece of mind. Centroid has been doing aftermarket CNC control for a long time, and they are right here in the US of A.

3.) I didn't post motor specs because the motor really isn't feasible as a hobby grade spindle motor... even used units on ebay go for about $2k+ for a motor/drive. I pulled them out of a machine in a scrap pile... so they were essentially free to me. It's a 1.5kw Lenze AC servo, 7k RPM motor. Anyone in industry will tell you that Lenze/AC Tech is a big hitter in the motor control world (I rank them above Allen Bradly for quality). I think most hobby guys would be looking at a DMM level servo motor for a hobby application, and no doubt they would work too.

4.) Most, if not all, servo motors have the encoder built in these days. I cannot use this for feedback to the Acorn even if I wanted to, there just isn't a provision for it in the drive. Past that, I would ONLY use a 1:1 encoder for rigid tapping, just too much at risk to try anything else. Also, the Acorn is capable of ridged tapping, cut2cut has his setup for it and he is simply using a nice 1.5hp motor and high quality VFD. I believe you have to have the Pro level software, but I'm not sure. He does have an encoder attached to his spindle to accomplish it, and as far as I know it works great.

Your idea about a 4th axis driving the spindle would likely work if you could figure out how to program it... but for the cost of an encoder, not worth it IMO.

I'll also include the negatives to the Acorn.

Hope this all helps! If you have more question, feel free to ask them in my build thread.

PZ

1.) I locked a part in the vice that was about as large as I figured I would ever machine and then created a program in Fusion 360 that mimicked moves I figured I would make (LOTS of adaptive). Then I ran it, adjusted velocity, and accel. I repeated this several times until I got it locked down with no missing steps. I got some very low numbers with the nMotion, but with the Acorn I'm at 100ipm in the x and y, and 65ipm in the z. One thing that GREATLY contributes to stepper noise and missed steps is "smoothing" always use it in Fusion adaptive processes. Even truing it to 0.0005" makes a HUGE difference. Acorn also has smoothing built in, once I turned that on, things got even better. After all of this was said and done, and I ran a few parts I realized that missing steps is more often than not related to bad programming. Asking the controller to process 200 lines of G code to go around a 0.5" radius makes no sense. The "noise" comes from the stepper constantly changing speed going though an arc.. and adaptive moves will do it all the time, so be careful.

2.) I kinda answered this with #1, but SMOOTHING! Turn smoothing on and run the same path again and see what it does. What you gain by going to the Acorn is mostly piece of mind, but there are also things like built in smoothing, great documentation, and their only tech support (fourm) is great. The nMotion/M3 can get the job done, but it's not the quality I was looking for. When I realized the estop circuit was a normally open circuit, that was kinda the icing on the cake for me. I take safety very seriously and a normally open estop circuit is a HUGE no, no. If they cut that very simple corner, where else did they cut corners? Like I said, nMotion and M3 will get it done, but I like piece of mind. Centroid has been doing aftermarket CNC control for a long time, and they are right here in the US of A.

3.) I didn't post motor specs because the motor really isn't feasible as a hobby grade spindle motor... even used units on ebay go for about $2k+ for a motor/drive. I pulled them out of a machine in a scrap pile... so they were essentially free to me. It's a 1.5kw Lenze AC servo, 7k RPM motor. Anyone in industry will tell you that Lenze/AC Tech is a big hitter in the motor control world (I rank them above Allen Bradly for quality). I think most hobby guys would be looking at a DMM level servo motor for a hobby application, and no doubt they would work too.

4.) Most, if not all, servo motors have the encoder built in these days. I cannot use this for feedback to the Acorn even if I wanted to, there just isn't a provision for it in the drive. Past that, I would ONLY use a 1:1 encoder for rigid tapping, just too much at risk to try anything else. Also, the Acorn is capable of ridged tapping, cut2cut has his setup for it and he is simply using a nice 1.5hp motor and high quality VFD. I believe you have to have the Pro level software, but I'm not sure. He does have an encoder attached to his spindle to accomplish it, and as far as I know it works great.

Your idea about a 4th axis driving the spindle would likely work if you could figure out how to program it... but for the cost of an encoder, not worth it IMO.

I'll also include the negatives to the Acorn.

- It's more expensive

- Software can get expensive if you want full probing cycles

- It's only 4 axis capable

- Limited I/O

- You have to have the Pro version of the software to run the MPG

- MPG is expensive compared to others (but it's very nice, and wireless!)

Hope this all helps! If you have more question, feel free to ask them in my build thread.

PZ

Hi PZ,

Thank you for the extensive answers. I am sure I will have more question as I progress.

I have the standard $175 Mach3 version that was available Dec 2017, Version R3.043.066 I miss-understood the PM940M literature at the time of purchase and thought that the nmotion only had a parallel port interface so while waiting for the arrival of the Mill from China I looked around for an old PC that would still have a parallel port. I found a pretty good machine on Craigslist, Gateway with Intel quad processor running at 2.6GHz and 4GB RAM. I replaced the Vista OS with 32 bit Win7 Enterprise so it only accesses 3GB of the memory. From my perspective, another disadvantage of the Acorn is that it requires Win10. I have a number of expensive software programs that do not run on Win10 so I have all of my other machines running on Win7....

So tonight, I mounted a dial gauge in my 100lb vise (photo) and tested the x-axis motion... to try out a simpler version of your speed test. My 940M came with a memory stick with a Mach3 profile already programed: the x-axis set to a max velocity of 50in/sec and an acceleration of 20in/sec-sec. I wrote some code that basically moved the x-axis off the gauge by an inch then ran the x-stage back and forth 3 ins. several times at a test velocity and acceleration and then returned the spindle back to the dial gauge to see if the setting had change. I figured that 3 inch of travel would always be more than enough to ensure that the motion had always reached the coasting velocity. I put in a 0.5 sec. pause at the end of each movement just so I would have time to shut the process down should something go really badly. At the end of the motion the stage moved back to the zero position and stopped so I could measure any error due to missing steps. I could not see any change on the dial gauge reading, that is, it it returned to the zero each time. Here was about 0.003 backlash so I the code with the motion always approaching the gauge from the same direction to avoid this. (The backlash is a screw and bearing problem and not a stepper or Mach3 problem and can be compensated for.) I took the velocity up to 150in/min and acceleration up to 40in/sec-sec. I ran this, and other slower speeds several times and never saw any positioning error, except one time when it may have been operator error and the stepper just spun and the table never moved at all! I am not for sure what that was about and I could not repeat it? The vise and dial gauge was the table load. I did not turn on the spindle as I wanted to wanted to always touch to the same point on an end mill. What I did observe in all of this and I hope to correct was that at the highest velocity and de-acceleration to a stop, 40 in./sec-sec the entire mill would rock just a bit.... an unwanted vibration. I am guessing one of my stand corners is not sitting on the floor with the same pressure as the other three corners. It could also simply be that the 200 lb. electronics control box, which is hanging on the side of my vertical post, causes the mill to wobble. I should probably put a post under it and take a bit of the weight off of the lathe vertical. I do not really see any reason to have such a high acceleration setting as it represents a small portion of the time of each movement. I did not try to go any faster as I was called away.

I tend to think that if there is going to be missing steps they are most likely to occur during the acceleration/de-acceleration as this is when the stepper is working the hardest. Once at speed the stepper just has to over come stage friction and force to drive a cutter into the material.

When I find a little more time I will test the y-axis and then maybe the z-axis. Then I can move on to test more complicated motions where at least two axis are driven at the same time. I do not expect to do very well on the z-axis as I have not removed the crank/worm gear to screw drive and it makes considerable noise at is flops back and forth. ( I hate to give up this manual vertical means.) However, I expect that vibration or jerking of many forms on the mill will translate to jerking the stepper motors and might cause a micro-step error if the velocity/acceleration settings are near the limit of performance.

I do agree with you about the estop and safety. It is a serious issue. I will take the cover all of my switch box and measure the switch to see if it is normally open or closed. The drawings show it as being unsafe, but then why should I believe the drawing. Maybe they updated the design since your machine was built. For safe operation, if an estop wire comes loose at the stop should be activated. If mine is not that way, I may look to see if there is a fix for this.

Thank you for the extensive answers. I am sure I will have more question as I progress.

I have the standard $175 Mach3 version that was available Dec 2017, Version R3.043.066 I miss-understood the PM940M literature at the time of purchase and thought that the nmotion only had a parallel port interface so while waiting for the arrival of the Mill from China I looked around for an old PC that would still have a parallel port. I found a pretty good machine on Craigslist, Gateway with Intel quad processor running at 2.6GHz and 4GB RAM. I replaced the Vista OS with 32 bit Win7 Enterprise so it only accesses 3GB of the memory. From my perspective, another disadvantage of the Acorn is that it requires Win10. I have a number of expensive software programs that do not run on Win10 so I have all of my other machines running on Win7....

So tonight, I mounted a dial gauge in my 100lb vise (photo) and tested the x-axis motion... to try out a simpler version of your speed test. My 940M came with a memory stick with a Mach3 profile already programed: the x-axis set to a max velocity of 50in/sec and an acceleration of 20in/sec-sec. I wrote some code that basically moved the x-axis off the gauge by an inch then ran the x-stage back and forth 3 ins. several times at a test velocity and acceleration and then returned the spindle back to the dial gauge to see if the setting had change. I figured that 3 inch of travel would always be more than enough to ensure that the motion had always reached the coasting velocity. I put in a 0.5 sec. pause at the end of each movement just so I would have time to shut the process down should something go really badly. At the end of the motion the stage moved back to the zero position and stopped so I could measure any error due to missing steps. I could not see any change on the dial gauge reading, that is, it it returned to the zero each time. Here was about 0.003 backlash so I the code with the motion always approaching the gauge from the same direction to avoid this. (The backlash is a screw and bearing problem and not a stepper or Mach3 problem and can be compensated for.) I took the velocity up to 150in/min and acceleration up to 40in/sec-sec. I ran this, and other slower speeds several times and never saw any positioning error, except one time when it may have been operator error and the stepper just spun and the table never moved at all! I am not for sure what that was about and I could not repeat it? The vise and dial gauge was the table load. I did not turn on the spindle as I wanted to wanted to always touch to the same point on an end mill. What I did observe in all of this and I hope to correct was that at the highest velocity and de-acceleration to a stop, 40 in./sec-sec the entire mill would rock just a bit.... an unwanted vibration. I am guessing one of my stand corners is not sitting on the floor with the same pressure as the other three corners. It could also simply be that the 200 lb. electronics control box, which is hanging on the side of my vertical post, causes the mill to wobble. I should probably put a post under it and take a bit of the weight off of the lathe vertical. I do not really see any reason to have such a high acceleration setting as it represents a small portion of the time of each movement. I did not try to go any faster as I was called away.

I tend to think that if there is going to be missing steps they are most likely to occur during the acceleration/de-acceleration as this is when the stepper is working the hardest. Once at speed the stepper just has to over come stage friction and force to drive a cutter into the material.

When I find a little more time I will test the y-axis and then maybe the z-axis. Then I can move on to test more complicated motions where at least two axis are driven at the same time. I do not expect to do very well on the z-axis as I have not removed the crank/worm gear to screw drive and it makes considerable noise at is flops back and forth. ( I hate to give up this manual vertical means.) However, I expect that vibration or jerking of many forms on the mill will translate to jerking the stepper motors and might cause a micro-step error if the velocity/acceleration settings are near the limit of performance.

I do agree with you about the estop and safety. It is a serious issue. I will take the cover all of my switch box and measure the switch to see if it is normally open or closed. The drawings show it as being unsafe, but then why should I believe the drawing. Maybe they updated the design since your machine was built. For safe operation, if an estop wire comes loose at the stop should be activated. If mine is not that way, I may look to see if there is a fix for this.

When the stepper "spun but the table never moved at all" you where missing steps. In my experience a stepper won't miss just one step or micro step, it misses all the steps until the speed becomes low enough that it can actually get going again. Remember, if the motor misses a step, that means it basically stopped for an instant, but the controller is still driving it at what ever speed it was at when it missed the step, which means you essentially have unlimited acceleration. Think about it like this, you're on a train that is moving, and you fall off, you're not going to be able to get back on that train until it slows to the point you can catch it. So that sound you heard was the stepper trying to rotate, but not actually rotating (missing steps).

Hope this makes sense.

PZ

Hope this makes sense.

PZ