-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Joined

- Oct 27, 2016

- Messages

- 288

Hang on a sec, you have every known extra on that mill but no power feed on the X axis?

BTW nice looking setup.

David.

- Joined

- Oct 7, 2020

- Messages

- 2,335

It's there. You have to look a little closer.

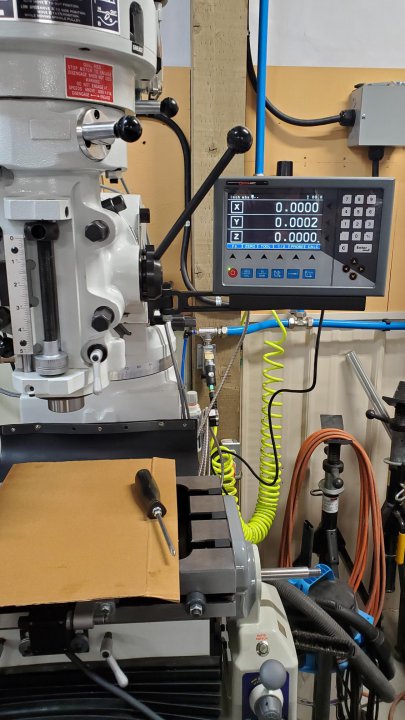

Here is a photo in the middle of installing everything.

Here is a photo in the middle of installing everything.

- Joined

- Oct 7, 2020

- Messages

- 2,335

I don't have a any experience other then the two that I own, I really like the MX-200 from Precision Matthews that I have on the mill. It's easy to read and easy to use.

I have the MX-100 on the lathe, if I had to do it over a would have spent the extra money and bought the MX-200 for the lathe as well.

I have the MX-100 on the lathe, if I had to do it over a would have spent the extra money and bought the MX-200 for the lathe as well.

- Joined

- Dec 26, 2015

- Messages

- 2,139

Tim, just out of curiosity, why do you feel that way? I have always been leery of the touch sensitive thin film plastic displays being rugged enough for shop environments and prefer the actual button with a tactile response. Nothing more frustrating than thinking you've entered a calibration value only to discover after the next cut that it didn't take the entry.I have the MX-100 on the lathe, if I had to do it over a would have spent the extra money and bought the MX-200 for the lathe as well.

- Joined

- Oct 7, 2020

- Messages

- 2,335

David, As you know I have limited experience with DROs and machining in general. The main reason I like the MX200 is the easy of use and the visibility of the numbers. Not that it is needed but the graphical display on drilling a bolt hole circle for instance is really nice. The display, the MX-200 displays real letter and words, where the MX-100 has the broke up LED type letters some of them almost look like a symbol rather then a letter. On my lathe with the MX100 during the day the light coming in the shop from behind me makes it harder to read the numbers. That and to get to some of the features which I my not have to get to very often are in sub menus that are not as easy as the MX200.

As far as the touch screen goes so far even with light gloves on, I haven't had a problem. I guess time will tell, especially when I get more experience and more confident on what I'm doing. Now I'm measuring twice or more entering the numbers thinking about it and making sure I have the numbers entered right before I ever make the cut. LOL

Tim

As far as the touch screen goes so far even with light gloves on, I haven't had a problem. I guess time will tell, especially when I get more experience and more confident on what I'm doing. Now I'm measuring twice or more entering the numbers thinking about it and making sure I have the numbers entered right before I ever make the cut. LOL

Tim

Every time I un-pallet one of these machines, it seems there is the cataclysmic moment where somebody is gonna lose a few fingers, or all will be fine. So far, so good.Mine had lift gate too. It was quite harrowing. I thought for sure it was going to fall off.

- Joined

- Oct 27, 2016

- Messages

- 288

Now I see it in the original photo, thanks, I thought that was odd.It's there. You have to look a little closer.

Here is a photo in the middle of installing everything.

View attachment 406325

Very nicely setup machine.

- Joined

- Oct 7, 2020

- Messages

- 2,335

Thank You