-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PM-833VT boring trouble

- Thread starter Tammy63

- Start date

I was surprised as well they were not metric. Even checked with a gage and against a 5/8-11 bolt. They are 2.5 inches long. I haven't installed any yet and I guess while I'm at it, need to check if I need to shim as well. Not sure how tight they need to be though.

- Joined

- Apr 20, 2019

- Messages

- 169

so I ordered some SS bolts from McMaster

That’s interesting! I’ll check my bolts when I reassemble the mill over winter.I now have 4 new grade 8 bolts

My mill had two brass shims at the front, to my uneducated eye I did wonder how much bearing surface there was with two shims like this.

This thread has helped me keep an eye out for a potential rigidity issue, thankyou.

- Joined

- Dec 26, 2015

- Messages

- 2,148

I'm finding this thread very interesting. I would have expected the 833 to have higher rigidity overall. The idea that the column-to-base bolts need replacing is kind of mind boggling considering this is a Taiwanese build. My Rong Fu 45 (which had integral power downfeed) was substantially more rigid than the PM-935 that replaced it - see attached. Not that this is apples-to-apples, as the 935 provides lots of head configuration options because of the RAM/knuckle that aren't available on a benchtop square-columm mill - but still . . . . .

I can't imagine getting tolerances better than ±0.001" in boring operations without power downfeed on the quill. The column interface is too sloppy if it's set up to move up/down as the means of boring dive, and feeding the quill manually during boring operations means inconsistent tool pressure and erratic results. And BTW, I have found that even the highest standard stainless fastener in this size range has about half the tensile strength of a steel grade 8 equivalent.

Thanks for posting.

I can't imagine getting tolerances better than ±0.001" in boring operations without power downfeed on the quill. The column interface is too sloppy if it's set up to move up/down as the means of boring dive, and feeding the quill manually during boring operations means inconsistent tool pressure and erratic results. And BTW, I have found that even the highest standard stainless fastener in this size range has about half the tensile strength of a steel grade 8 equivalent.

Thanks for posting.

Attachments

Just my thoughts but the holes are close to the radius on the column. The washers have a slight gap underneath due to resting on the radius and are not allowing for a good clamp. Hopefully this weekend I'll get them put in and check column movement. Still debating whether I want to make clearance for the washers or not use them.

I installed the bolts and tightened them to a calibrated that's #$%* tight. You can only use an open ended wrench due to clearance. Took the movement out of the column from .004" to .002". Now I need to run a part and see how it behaves.

Back at it and still not happy..

You can see how flat this is or should I say how it's not.

This is @ 93flbs and you can see the gap..

I cut some washers down and grinded the column down to remove as much of the rounded edges as possible and tightened all 4 bolts to 93flbs

And I can still move the column .001 and if a push with all I can I can get. 002

I don't know if I'm asking too much from this PM mill but I feel for what I paid for it and with PM posting it only has. 0003 of run-out and that's all it has I feel it should not have any movement in it..

You can see how flat this is or should I say how it's not.

This is @ 93flbs and you can see the gap..

I cut some washers down and grinded the column down to remove as much of the rounded edges as possible and tightened all 4 bolts to 93flbs

And I can still move the column .001 and if a push with all I can I can get. 002

I don't know if I'm asking too much from this PM mill but I feel for what I paid for it and with PM posting it only has. 0003 of run-out and that's all it has I feel it should not have any movement in it..

Attachments

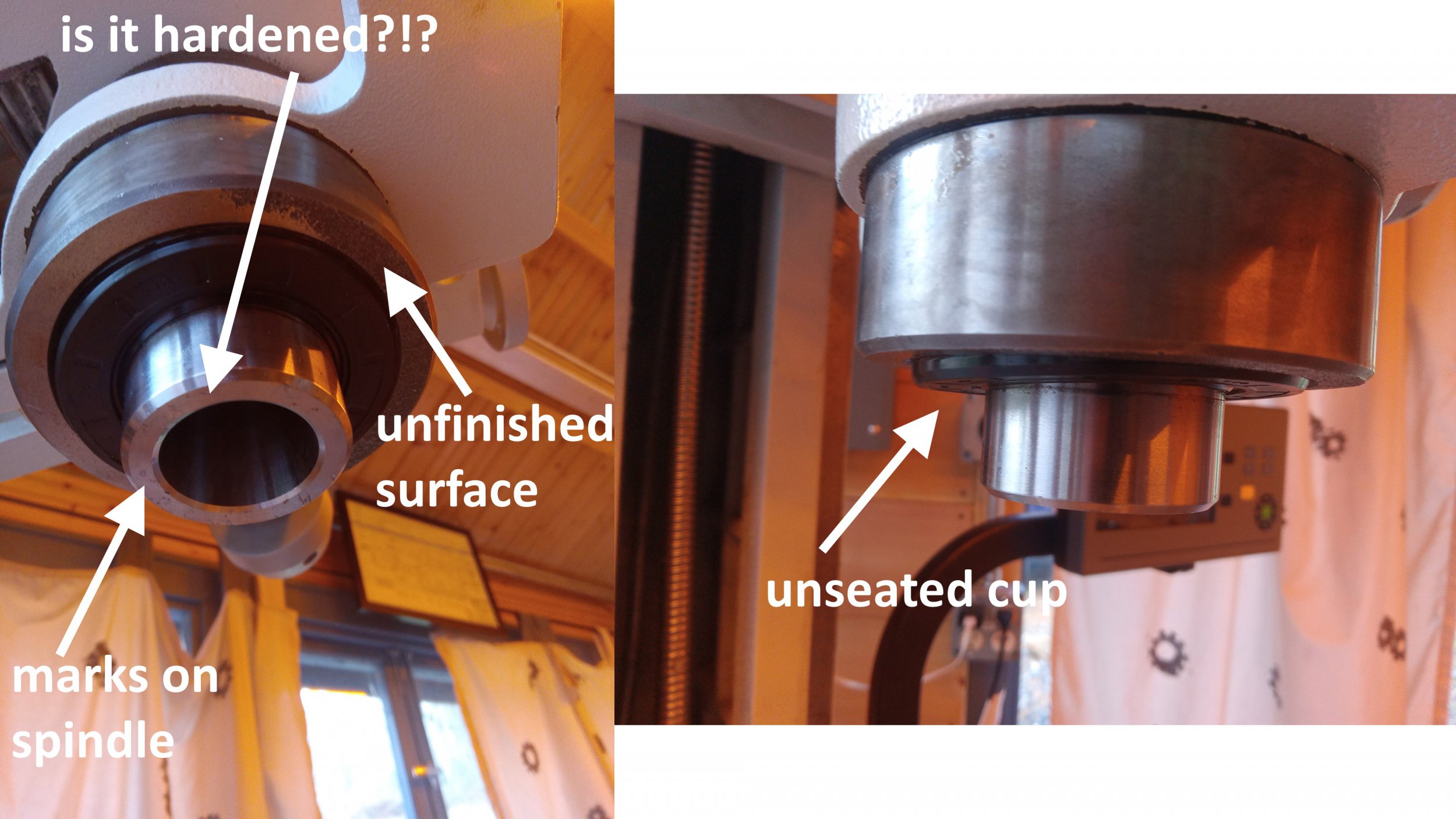

My experience with the PM833 has been miserable. Compared to the PM25, the PM833 is quite a disappointment. Roll pins where there should be bolts, overly long drawbar, all hand tapped bolt holes, unhardened spindle, bolts that were missing and uninstalled by the factory. Taiwanese seems to mean little, at least here. And frankly Chinese equipment has caught up. But the PM833 is probably still a value given the sheer weight and size of the castings.

YOUR ISSUE, most of the problems I noticed were in the head (especially play in the quill that might impact boring). I asked PM for a replacement head and they refused (although usually Matt is great):

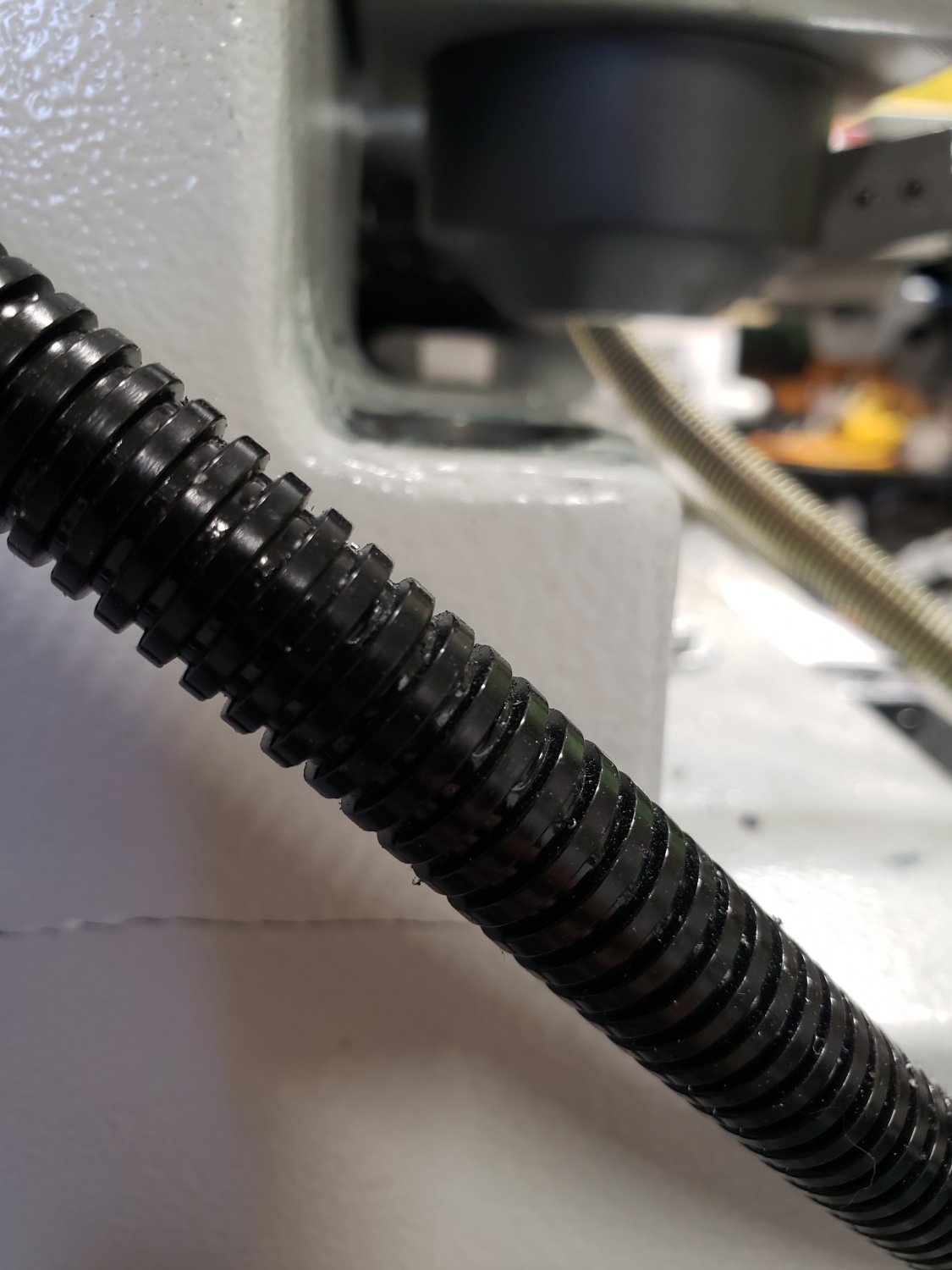

YOUR ISSUE might partially stem from quill slop. I noticed substantial radial play in my quill. The quill's slip fit is poorly toleranced:

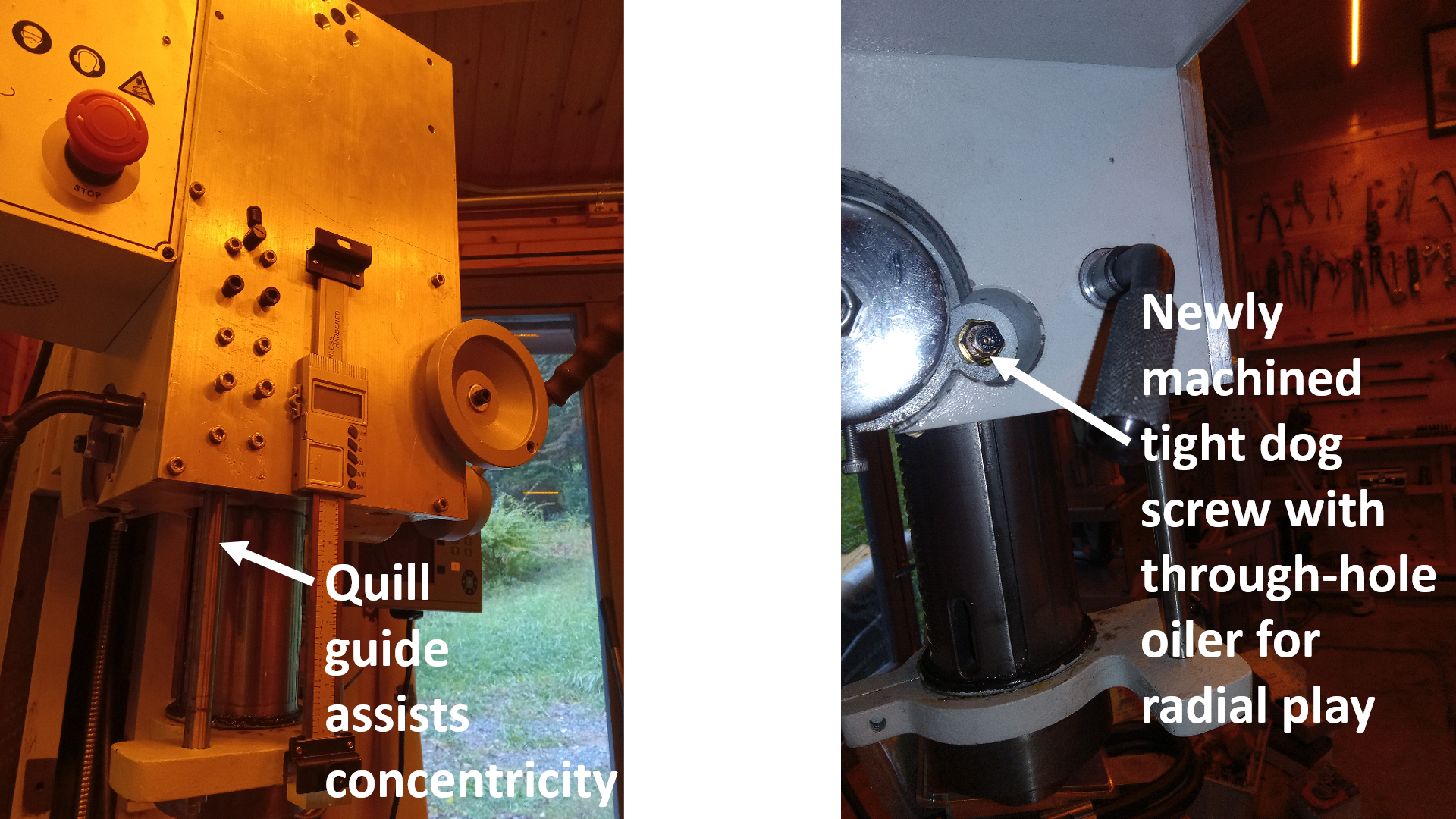

I've tried to fix this as shown:

This is all part of a CNC conversion, but at this point I should have simply paid for a Skyfire CNC through the American distributor (https://www.tripletreecnc.com/skyfire-svm-2). The PM833 was a mistake.

YOUR ISSUE, most of the problems I noticed were in the head (especially play in the quill that might impact boring). I asked PM for a replacement head and they refused (although usually Matt is great):

YOUR ISSUE might partially stem from quill slop. I noticed substantial radial play in my quill. The quill's slip fit is poorly toleranced:

I've tried to fix this as shown:

This is all part of a CNC conversion, but at this point I should have simply paid for a Skyfire CNC through the American distributor (https://www.tripletreecnc.com/skyfire-svm-2). The PM833 was a mistake.