I am considering getting a PM-833T and replacing the original single phase motor with a 3 phase motor and a VFD so I can get to a higher RPM (around 3,000.) It seems that the PM-833TV (electronic speed control version) will lose substantial power at low RPM due to the fact that it is the same gear ratio for the entire range. So my conclusion after checking and scouring the web for information that I am better off with a modified PM-833T vs getting the TV version.

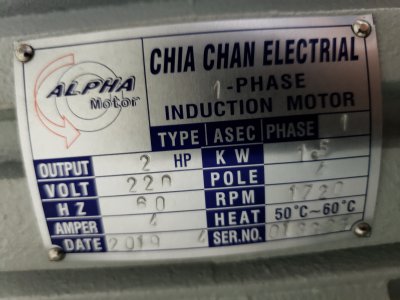

I am looking for information about the original single phase motor rated RPM. I could not find this information anywhere. I will greatly appreciate if one of the PM-833T owners can take a look and report back.

Any other ideas, shared experience or warnings are welcome.

Thank you!

Ariel

I am looking for information about the original single phase motor rated RPM. I could not find this information anywhere. I will greatly appreciate if one of the PM-833T owners can take a look and report back.

Any other ideas, shared experience or warnings are welcome.

Thank you!

Ariel