- Joined

- Jan 16, 2016

- Messages

- 302

THE PM-833T COMES WITH A FACTORY QUILL STOP .

UNFORTUNATELY , IT IS NOT VERY USEFUL .

IT CAN BE SET TO THE DESIRED HEIGHT BUT MOVES AS SOON AS YOU TAP IT .

IT ALSO CANNOT BE MOVED IN PRECISE INCREMENTS

WITH THE DESIRE TO HAVE A SOLID & ADJUSTABLE TO .001" STOP , I BOUGHT

AN "EDUCATED NUT" ( IT's GRADUATED ) THAT IS INTENDED FOR A BRIDGEPORT .

THESE THINGS ARE GREAT BECAUSE OF THE INSTANT UP/DOWN FEATURE

ADAPTING THIS TO THE PM MILL REQUIRES SOME NEW PARTS .

THE ORIGINAL CAST IRON BRACKET WAS REPLACED WITH PARTS CUT FROM STEEL .

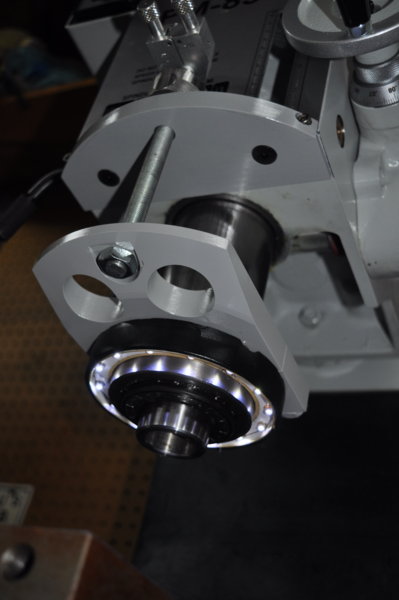

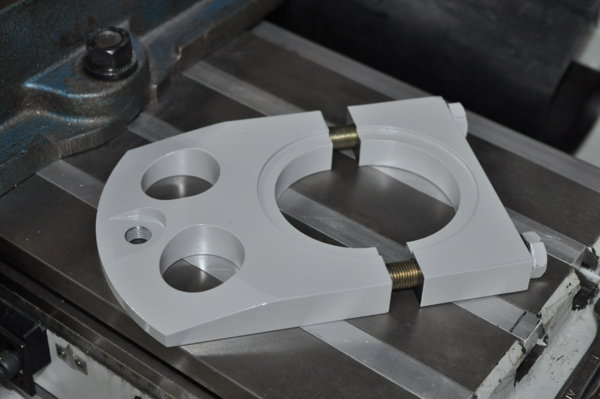

I WANTED A LOWER SECTION THAT IS EASILY REMOVABLE SO IT IS MADE TO CLAMP

ON THE QUILL IN TWO PARTS LIKE A CONNECTING ROD WITH MASSIVE 1/2-20 BOLTS .

IT WAS BORED OUT TO 2" AND THEN CHUCKED ON THE LATHE

MY HORVATH ECCENTRIC CHUCK ALLOWED ME TO CHUCK ON A DIAMETER THAT

ACTUALLY EXCEEDS THE SWING OF MY LATHE BY OFFSETTING THE CENTER !

THE UPPER SECTION ALSO NEEDS TO BE SOLIDLY MOUNTED . I ONLY HAD 3/16'

CLEARANCE BETWEEN THE MOVING PLATE & THE FIXED ONE OR I WOULD LOSE

SOME QUILL TRAVEL . IT WILL BOLT TO THE UNDERSIDE OF THE HEAD THROUGH

THE ORIGINAL QUILL STOP HOLE AND THE EXTRA ONE THEY PROVIDED FOR NO REASON .

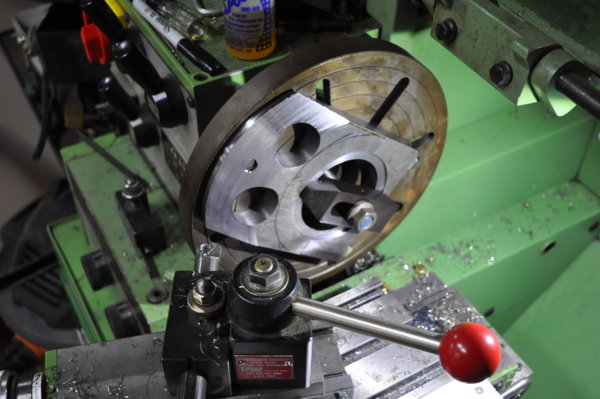

I LIKE THE USE OF CURVES SO THE FIXED SECTION WAS TURNED DOWN ON MY DRIVE PLATE .

IT ALSO IS SECURED BY TWO M5 CAP SCREWS THROUGH THE FACEPLATE HOLES .

IT IS AS SOLID AS A ROCK .

I PUT A MEGA-CHAMFER ON THE UNDERSIDE OF THE MOVING PLATE TO REDUCE MASS

AND REDUCE THE VISUAL OBSTRUCTION .

I FOUND A PRETTY CLOSE MATCH THE THE PAINT COLOR P-M USES SO IT WILL LOOK

LIKE IT BELONGS .

AS AN ADDED BONUS I CAN USE MY TEMPORARY NUT ON THE BOTTOM AND MAKE A STOP

THAT WORKS GOING UP OR DOWN .

UNFORTUNATELY , IT IS NOT VERY USEFUL .

IT CAN BE SET TO THE DESIRED HEIGHT BUT MOVES AS SOON AS YOU TAP IT .

IT ALSO CANNOT BE MOVED IN PRECISE INCREMENTS

WITH THE DESIRE TO HAVE A SOLID & ADJUSTABLE TO .001" STOP , I BOUGHT

AN "EDUCATED NUT" ( IT's GRADUATED ) THAT IS INTENDED FOR A BRIDGEPORT .

THESE THINGS ARE GREAT BECAUSE OF THE INSTANT UP/DOWN FEATURE

ADAPTING THIS TO THE PM MILL REQUIRES SOME NEW PARTS .

THE ORIGINAL CAST IRON BRACKET WAS REPLACED WITH PARTS CUT FROM STEEL .

I WANTED A LOWER SECTION THAT IS EASILY REMOVABLE SO IT IS MADE TO CLAMP

ON THE QUILL IN TWO PARTS LIKE A CONNECTING ROD WITH MASSIVE 1/2-20 BOLTS .

IT WAS BORED OUT TO 2" AND THEN CHUCKED ON THE LATHE

MY HORVATH ECCENTRIC CHUCK ALLOWED ME TO CHUCK ON A DIAMETER THAT

ACTUALLY EXCEEDS THE SWING OF MY LATHE BY OFFSETTING THE CENTER !

THE UPPER SECTION ALSO NEEDS TO BE SOLIDLY MOUNTED . I ONLY HAD 3/16'

CLEARANCE BETWEEN THE MOVING PLATE & THE FIXED ONE OR I WOULD LOSE

SOME QUILL TRAVEL . IT WILL BOLT TO THE UNDERSIDE OF THE HEAD THROUGH

THE ORIGINAL QUILL STOP HOLE AND THE EXTRA ONE THEY PROVIDED FOR NO REASON .

I LIKE THE USE OF CURVES SO THE FIXED SECTION WAS TURNED DOWN ON MY DRIVE PLATE .

IT ALSO IS SECURED BY TWO M5 CAP SCREWS THROUGH THE FACEPLATE HOLES .

IT IS AS SOLID AS A ROCK .

I PUT A MEGA-CHAMFER ON THE UNDERSIDE OF THE MOVING PLATE TO REDUCE MASS

AND REDUCE THE VISUAL OBSTRUCTION .

I FOUND A PRETTY CLOSE MATCH THE THE PAINT COLOR P-M USES SO IT WILL LOOK

LIKE IT BELONGS .

AS AN ADDED BONUS I CAN USE MY TEMPORARY NUT ON THE BOTTOM AND MAKE A STOP

THAT WORKS GOING UP OR DOWN .