- Joined

- Dec 26, 2015

- Messages

- 2,139

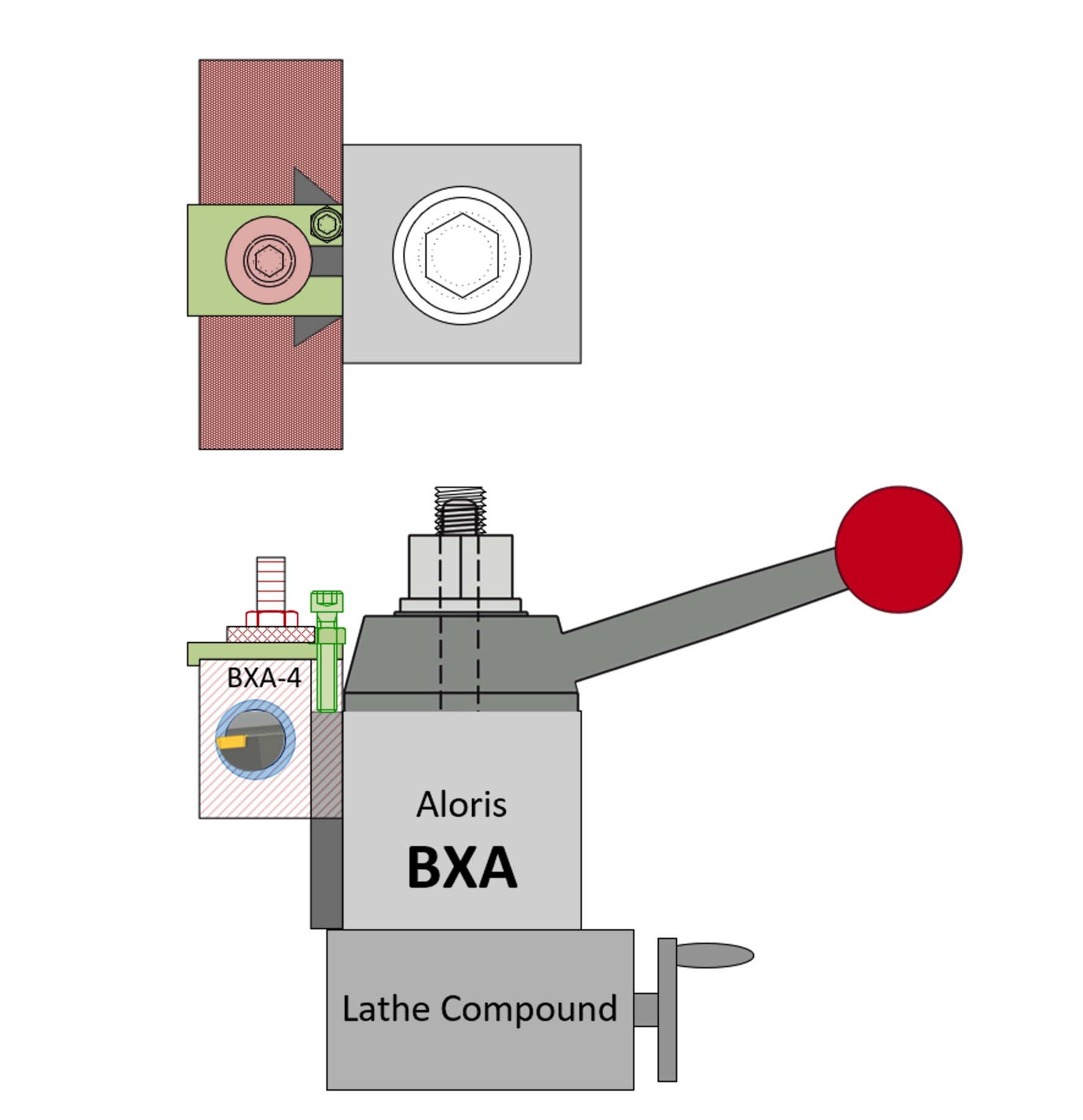

If you are having trouble getting a toolholder high enough to make centerline, make yourself an elevation fixture for the QC tool holder.

It looks like this:

Below is a drawing to further illustrated the concept. It took me 15 minutes to make one of these on the mill. The fixture slides between the top of the QC tool holder and the locking nut (red in the drawing below) and is locked into position there. Then the screw (shown in green) is lowered, pushing against the top of the wedge of the QCTP, which in turn elevates the tool holder. If that screw has a locknut, that will secure the screw such that the tool height is maintained when the tool is removed and reinstalled. Hope this is clear. It functions the same way as putting a block under the height adjustment knob, but stays attached to the tool holder when it's removed.

It looks like this:

Below is a drawing to further illustrated the concept. It took me 15 minutes to make one of these on the mill. The fixture slides between the top of the QC tool holder and the locking nut (red in the drawing below) and is locked into position there. Then the screw (shown in green) is lowered, pushing against the top of the wedge of the QCTP, which in turn elevates the tool holder. If that screw has a locknut, that will secure the screw such that the tool height is maintained when the tool is removed and reinstalled. Hope this is clear. It functions the same way as putting a block under the height adjustment knob, but stays attached to the tool holder when it's removed.