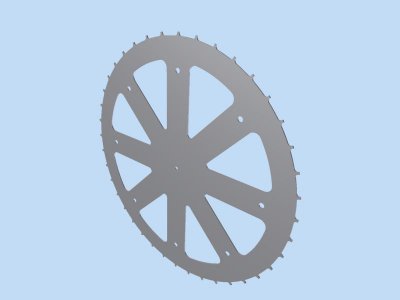

I’m in the beginning stages of a project where I will be machining two large chain sprockets (picture a 40-tooth bicycle chainring, but at 20” diameter). For the curious, I am building 2 automatic, solar powered compost drum rotators.

The material will be 14ga steel (or stainless). To save time and make sure the sprockets end up the same, I plan to bolt the two blanks together and mill them at the same time. The blanks will be circles with the outside diameter being the top of each tooth.

Once set up, the plan is to plunge through with an endmill, then rotate the rotisserie table 6 degrees (milling), withdraw the end mill, rotate another 3 degrees, and plunge through again. I’ll repeat this process 40 times to create the sprockets. The 10” rotary table I have has a good perimeter degree gauge so I’m confident I can hit the angles accurately enough. I also plan on having a support block clamped to the mill table to brace the blanks while plunging.

My question, is there a type of endmill that is better for plunging through without walking or wobbling? The end mill I’ll need will be something like 23/64” or 9mm diameter.

The material will be 14ga steel (or stainless). To save time and make sure the sprockets end up the same, I plan to bolt the two blanks together and mill them at the same time. The blanks will be circles with the outside diameter being the top of each tooth.

Once set up, the plan is to plunge through with an endmill, then rotate the rotisserie table 6 degrees (milling), withdraw the end mill, rotate another 3 degrees, and plunge through again. I’ll repeat this process 40 times to create the sprockets. The 10” rotary table I have has a good perimeter degree gauge so I’m confident I can hit the angles accurately enough. I also plan on having a support block clamped to the mill table to brace the blanks while plunging.

My question, is there a type of endmill that is better for plunging through without walking or wobbling? The end mill I’ll need will be something like 23/64” or 9mm diameter.