- Joined

- Aug 23, 2020

- Messages

- 55

Some things I've come up with for the course.

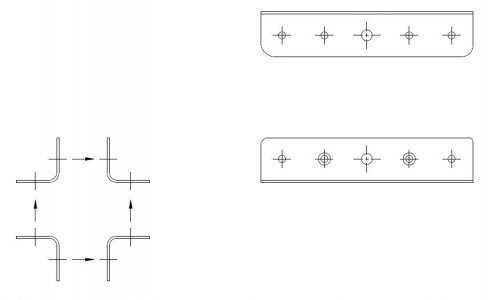

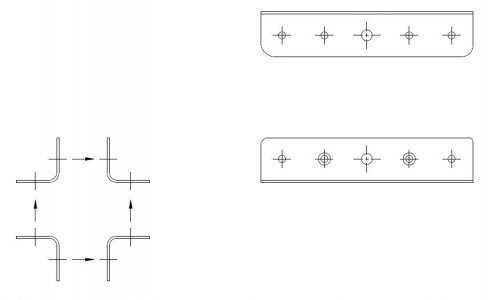

The goals would be simply to make the angles bent from sheet-metal and drill holes in a straight line across the flanges. Different holes can have different functions, such as rivets, countersunk rivets, or screws/bolts. Lots to talk about just with that. After the group makes these angles, they can assemble the pieces together. Alignment of the respective pieces requires matching the holes - starting with pilot holes and up-size drilling would be necessary.

Another lesson would use the lathe to make a simple bushing from round stock. To simplify, we can start with tube stock. To make it more challenging, the bushing can have a shoulder. Even more challenging would be to control the diameter of the bushing so that it press-fits into a hole (and drill+ream the mating hole).

Both of these offer a step-by-step series of operations, and time permitting allow the group to accomplish more or less tasks, depending on their ability and time available.

The goals would be simply to make the angles bent from sheet-metal and drill holes in a straight line across the flanges. Different holes can have different functions, such as rivets, countersunk rivets, or screws/bolts. Lots to talk about just with that. After the group makes these angles, they can assemble the pieces together. Alignment of the respective pieces requires matching the holes - starting with pilot holes and up-size drilling would be necessary.

Another lesson would use the lathe to make a simple bushing from round stock. To simplify, we can start with tube stock. To make it more challenging, the bushing can have a shoulder. Even more challenging would be to control the diameter of the bushing so that it press-fits into a hole (and drill+ream the mating hole).

Both of these offer a step-by-step series of operations, and time permitting allow the group to accomplish more or less tasks, depending on their ability and time available.