Greetings,

I've had Box #2 for a full week now. Thank you all for your patience. Since I last posted here, priorities of the real world have prevailed, until this evening. So, I had a week to consider options. My thinking is that the wood/wood screw interface just won't hold up to the pounding, regardless of quantity. Installing inserts and using machine screws would be more robust but I expect the plywood would get pounded out (releasing the inserts) pretty quickly. I considered cutting a rectangle of 1/4" ply, snug fit to the box interior, and gluing it to the inside of the lid, to take some of the lateral loads off of the screws. But, I think that would just break the corner joints on the side panels. I decided to weld up a frame out of 3/4 x 3/4 x 1/8 angle iron.

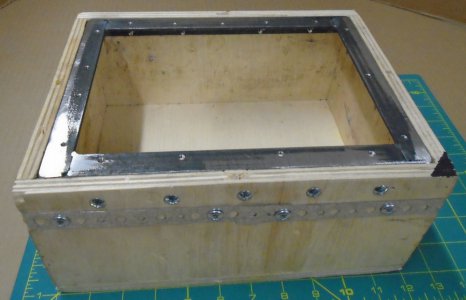

Here it is mounted in the box.

The screw holes were laid out coarsely with a measuring tape so I made the hole pattern obviously asymmetrical to make R&R a no-brainer. I ended up with 16 screws to hold the lid to the frame and the same number for frame to box. I hope everyone uses a power screwdriver to R&R the cover so you won't think bad thoughts (about me).

The screws are 8-32 x 3/4 long, truss head (the type commonly used to hold drawer pulls). Snug is good enough.

If I were starting from scratch, I think I would build two frames (top and bottom) and just screw the 6 plywood panels on. No glue, no nails. Time will tell how the frame approach holds up.

Tuesday I'll make my selections, add some goodies and repackage. Maybe get it in the mail Tuesday, Wednesday for sure.