- Joined

- Dec 30, 2014

- Messages

- 259

I went thru all of the items brought up so far. I did tighten up the gibs more, but I think they we okay.

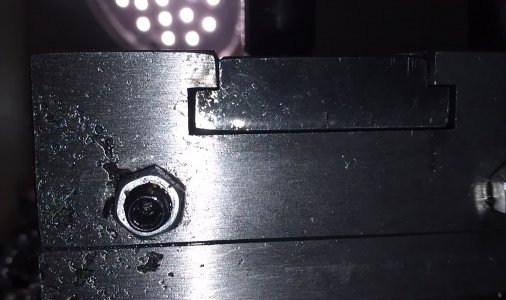

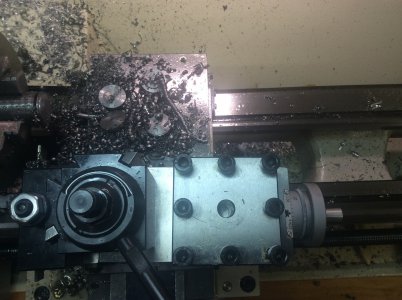

I think my tool post and compound need some attention. The fit must not be right because I can see it Rock forward a bit under a load. I'll work on that issue.

i was able to rotate the compound in line with the cross slide to give the tool post more surface under it instead of sitting skew across the end of the compound. That helped a lot, so I think I'm going to take a good look at the way it mounts and see what I can do to fix it.

Question abouts chips during parting. Seems like I see this with aluminum as well as steel. Toward the beginning of the cut the chip is long, continuous and shinny on the under side as it comes off. This, while the cut is smooth and no issues. But, as the cut progresses the chip starts to change to a flat broken flat color and sort of looks like fudge, not shinny. (is that how you spell something that shines?)

anyhow, the toolpost and compound seem to be the biggest part of my trouble.

thanks for helping me out! Let me know what the chips mean? I'm not sure it is the feed changing due to decreasing diameter but that makes the most sense, unless it is related to heat as it starts getting deeper and heats up?

jim

I think my tool post and compound need some attention. The fit must not be right because I can see it Rock forward a bit under a load. I'll work on that issue.

i was able to rotate the compound in line with the cross slide to give the tool post more surface under it instead of sitting skew across the end of the compound. That helped a lot, so I think I'm going to take a good look at the way it mounts and see what I can do to fix it.

Question abouts chips during parting. Seems like I see this with aluminum as well as steel. Toward the beginning of the cut the chip is long, continuous and shinny on the under side as it comes off. This, while the cut is smooth and no issues. But, as the cut progresses the chip starts to change to a flat broken flat color and sort of looks like fudge, not shinny. (is that how you spell something that shines?)

anyhow, the toolpost and compound seem to be the biggest part of my trouble.

thanks for helping me out! Let me know what the chips mean? I'm not sure it is the feed changing due to decreasing diameter but that makes the most sense, unless it is related to heat as it starts getting deeper and heats up?

jim