- Joined

- Dec 30, 2014

- Messages

- 259

Guys,

I spent a few hours yesterday practicing parting off on the lathe. First let me say I'm sort of talking myself thru this because I think I have read up on the procedure and watched countless videos on the subject. Yesterday I thought I was doing pretty good on the 6061. Today I did a few more with the aluminum and didn't have any problems. So, I pop a 1" piece of 1018 in the chuck and the first attempt goes pretty good. Then the next one starts to chatter like crazy and I have been out there for an hour with no luck finding out what changed.

I'm using a Grizzly G0752 using an import AXA QCTP. I have rigged up a drip oiler because I want to be able to keep both hands on the hand wheel of the cross slide for better control and more even feed.

When it is going well, I part off a narrow piece, loosen the jaws and pull out a bit more for another go. This way I don't have to loosen the lock on the apron.

i have re sharpened the cutter, tried a 1/8" cutter (I was using 5/64") I tried choking up the cutter in the holder to the point that there is no way I would make it thru to the center. I tried slower and faster rpm. I had been using about 350rpm. I re chucked the part. I even have two holders and they both behave the same. I went back to 6061 and although I was able to get it done, I could tell it wasn't working as easily as before. I checked the tool square to the stock and on center. And, I'm not even getting far enough into the work to create and side bind on the tool.

Hum... Frustrating part is I was just about to think I was figuring this out, now I feel like I need sharper teeth so I can try chewing it off!

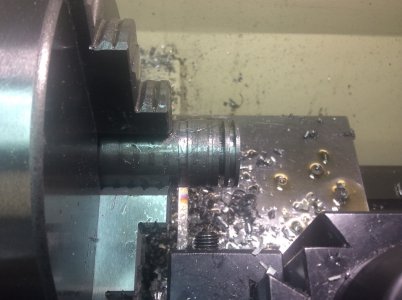

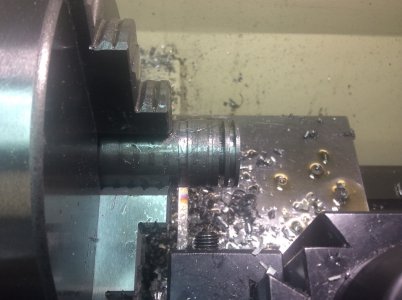

Here are a few pics of the setup.

I spent a few hours yesterday practicing parting off on the lathe. First let me say I'm sort of talking myself thru this because I think I have read up on the procedure and watched countless videos on the subject. Yesterday I thought I was doing pretty good on the 6061. Today I did a few more with the aluminum and didn't have any problems. So, I pop a 1" piece of 1018 in the chuck and the first attempt goes pretty good. Then the next one starts to chatter like crazy and I have been out there for an hour with no luck finding out what changed.

I'm using a Grizzly G0752 using an import AXA QCTP. I have rigged up a drip oiler because I want to be able to keep both hands on the hand wheel of the cross slide for better control and more even feed.

When it is going well, I part off a narrow piece, loosen the jaws and pull out a bit more for another go. This way I don't have to loosen the lock on the apron.

i have re sharpened the cutter, tried a 1/8" cutter (I was using 5/64") I tried choking up the cutter in the holder to the point that there is no way I would make it thru to the center. I tried slower and faster rpm. I had been using about 350rpm. I re chucked the part. I even have two holders and they both behave the same. I went back to 6061 and although I was able to get it done, I could tell it wasn't working as easily as before. I checked the tool square to the stock and on center. And, I'm not even getting far enough into the work to create and side bind on the tool.

Hum... Frustrating part is I was just about to think I was figuring this out, now I feel like I need sharper teeth so I can try chewing it off!

Here are a few pics of the setup.