I used electrolysis to remove rust from some very rusty files recently. I used a litter box for the container and welded up a positive electrode from some old threaded ends from some silo staves. This went on the bottom of the tray, followed by an insulating grid made from a fluorescent light fixture grid and a negative electrode made from an old breeze box fan grille. The files were placed on negative electrode and a bath was made from a salt solution using dregs from cleaning out the water softener. I used a constant current supply and set the current at 10 amps which set the voltage at about 6 volts. After six hours, it had done a decent job of removing some very heavy rust encrustations.

If using a sodium chloride solution as the electrolyte, chlorine gas can be generated so the process should be carried out outdoors. It also seemed to me that the solution became quite alkaline due to chlorine being liberated , replaced by the hydroxyl ion so protective gloves are warranted. Washing soda can be used for the electrolyte, which will remove the possibility of chlorine gas but there is still some gassing evident. I would expect the gasses are CO2, hydrogen, and oxygen so the process is still best carried out outdoors.

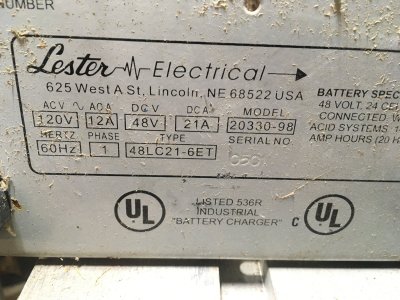

View attachment 516715